KBK Light Crane Manufacturer & Supplier Overview| Top 10 Supplier

Light kbk crane manufacturer and supplier overview. Check top 10 light kbk crane manufacturers & suppliers, kbk crane design, standards, features, prices.

Category: Featured

Your Trusted Overhead KBK Crane Manufacturer & Supplier

KBK Light Crane Manufacturer & Supplier Overview

Top 10 Light KBK Crane Manufacturers & Suppliers, KBK Crane Design, Standards, Features, Prices

Light kbk crane manufacturer and supplier overview. Check top 10 light kbk crane manufacturers & suppliers, kbk crane design, standards, features, prices.

Comprehensive Guide on Top KBK Crane Manufacturers and Suppliers

Choosing the right KBK crane manufacturer and supplier is a critical decision for industries relying on efficient material handling systems. The selection process involves various considerations to ensure the optimal performance and reliability of the crane systems. In this comprehensive guide, we delve into the importance of making informed choices when it comes to KBK crane manufacturers and suppliers, exploring key factors that influence the decision-making process.

Importance of Choosing the Right KBK Crane Manufacturer

Selecting a reputable KBK crane manufacturer is crucial for ensuring the quality, safety, and efficiency of your material handling operations. The manufacturer's expertise, commitment to innovation, and adherence to industry standards significantly impact the performance and longevity of the KBK crane system.

Considerations for Selecting KBK Crane Suppliers

Beyond the manufacturing process, the choice of a reliable KBK crane supplier plays a vital role in the overall success of your material handling solution. Factors such as delivery times, customer support, and the availability of spare parts contribute to a smooth and uninterrupted operation of the KBK crane.

Key Factors Influencing the Decision

Several key factors influence the decision when choosing a KBK crane manufacturer and supplier. These factors include the specific application requirements, industry standards, customization options, and after-sales support. Understanding and prioritizing these factors will guide you towards making an informed and beneficial decision for your material handling needs.

In the following sections, we will explore the top KBK crane manufacturers and suppliers in various countries, examine typical designs and features, and provide insights into the global KBK crane market. This guide aims to equip industries with the knowledge needed to navigate the selection process and make choices that align with their operational goals.

Top KBK Crane Manufacturers and Suppliers by Country

Germany

Konecranes:

Overview: Konecranes is a global leader in lifting equipment, including KBK crane systems. With a strong presence in Germany, the company is known for its advanced crane technology and commitment to safety and reliability.

Key Features:

Innovative KBK crane solutions.

Emphasis on safety features and precision.

Customizable designs to suit diverse industrial needs.

Applications: Konecranes' KBK crane systems find applications across various industries, including manufacturing, logistics, and automotive.

STAHL CraneSystems:

Overview: STAHL CraneSystems is a German company specializing in crane technology, and they offer a range of KBK crane solutions. They are recognized for their quality engineering and reliable material handling solutions.

Key Features:

Diverse KBK crane configurations for different applications.

Focus on durability and performance.

Customization options based on specific requirements.

Applications: STAHL CraneSystems' KBK crane systems are utilized in manufacturing facilities, warehouses, and industrial environments.

These suppliers are well-regarded in the German KBK crane industry, and their offerings encompass a wide range of solutions to meet the diverse needs of businesses in the region. It's advisable to conduct thorough research and consider specific project requirements when choosing a supplier for KBK crane systems.

United States

In the United States, there are several reputable KBK crane manufacturers and suppliers. Here are two well-known companies in the KBK crane industry:

Gorbel Inc.:

Overview: Gorbel Inc. is a leading material handling equipment manufacturer based in the United States. They offer a variety of crane solutions, including KBK crane systems. Gorbel is recognized for its commitment to innovation and providing high-quality lifting solutions.

Key Features:

Diverse range of KBK crane systems for different applications.

Emphasis on safety features and ergonomic design.

Customization options to meet specific requirements.

Applications: Gorbel's KBK crane systems are used in industries such as manufacturing, automotive, and warehousing.

Demag Cranes and Components:

Overview: Demag Cranes and Components, a subsidiary of Terex Corporation, is a global player in the crane manufacturing industry. They provide various material handling solutions, including KBK crane systems, known for their reliability and advanced technology.

Key Features:

High-performance KBK crane systems with advanced control features.

Adaptability to different industrial environments.

Comprehensive product range catering to various load capacities.

Applications: Demag's KBK crane systems find applications in manufacturing, logistics, and other industries across the United States.

These companies have a strong presence and reputation in the U.S. market, offering quality KBK crane systems designed to enhance material handling efficiency and safety. When selecting a supplier, it's advisable to evaluate specific project requirements and consider factors such as load capacities, customization options, and after-sales support.

China

In China, a rapidly growing manufacturing hub, several key players dominate the KBK crane industry. Here are two notable companies recognized for their contributions to the Chinese KBK crane sector:

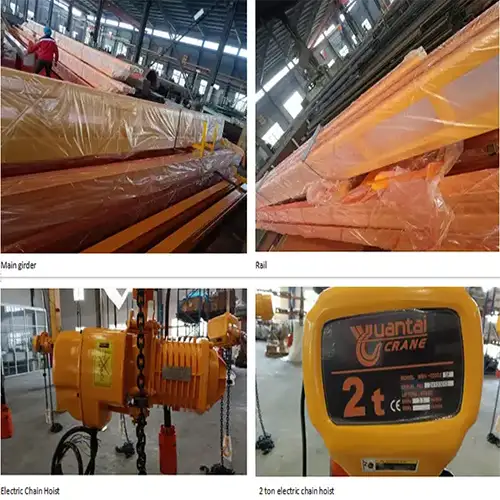

Henan Yuantai Crane Machinery Group Co., Ltd.:

Overview: Henan Yuantai Crane Machinery Group, based in China, is a prominent manufacturer specializing in various types of cranes, including KBK crane systems. The company is known for its comprehensive range of lifting solutions and a strong commitment to quality.

Key Features:

Diverse KBK crane system designs, including single-girder and double-girder configurations.

Customization options for specific industry requirements.

Adherence to international standards for safety and performance.

Applications: Henan Hengyuan's KBK crane systems are widely applied in manufacturing, logistics, and construction industries across China.

Nucleon (Xinxiang) Crane Co., Ltd.:

Overview: Nucleon is a leading crane manufacturer with operations in Xinxiang, China. The company is recognized for its innovation and advanced crane technologies. Nucleon provides a range of KBK crane systems designed for efficient material handling in various applications.

Key Features:

High-performance KBK crane systems suitable for different load capacities.

Focus on technological advancements and product reliability.

Customization options to meet specific client needs.

Applications: Nucleon's KBK crane systems find applications in manufacturing, warehouses, and other industrial sectors in China.

Both of these companies have established themselves as key players in the Chinese KBK crane industry, offering reliable and innovative solutions to meet the diverse needs of the country's growing manufacturing landscape. When considering a KBK crane supplier in China, factors such as product range, customization options, and adherence to safety standards should be carefully evaluated.

Japan

In Japan, a country known for its advanced technology and precision engineering, there are reputable KBK crane manufacturers and trusted suppliers. Here are notable companies contributing to the Japanese KBK crane market:

KITO Corporation:

Overview: KITO Corporation is a renowned Japanese company specializing in the manufacturing of lifting equipment, including KBK crane systems. With a global presence, KITO is known for its high-quality and technologically advanced lifting solutions.

Key Features:

Diverse KBK crane system designs with a focus on safety and efficiency.

Innovation in material handling technology, including electric chain hoists.

Adherence to stringent quality standards.

Applications: KITO's KBK crane systems are widely used in various industries in Japan, including manufacturing, logistics, and construction.

Mitsubishi Electric Corporation:

Overview: Mitsubishi Electric is a Japanese multinational company with a broad range of products and services. In the field of cranes, Mitsubishi Electric provides advanced automation solutions, including KBK crane systems.

Key Features:

Integration of cutting-edge technologies for precise and efficient material handling.

Customizable KBK crane solutions to meet specific industry needs.

Strong emphasis on energy efficiency and environmental sustainability.

Applications: Mitsubishi Electric's KBK crane systems are applied in manufacturing processes, warehouses, and other industrial settings in Japan.

These companies exemplify the commitment to quality and technological innovation characteristic of the Japanese manufacturing landscape. When considering a KBK crane manufacturer or supplier in Japan, factors such as technology integration, customization options, and a track record of reliability should be taken into account.

United Kingdom

In the United Kingdom, there are leading KBK crane manufacturers and recognized suppliers that contribute to the country's material handling solutions. Here are notable companies in the UK's KBK crane industry:

Pelloby Ltd:

Overview: Pelloby is a leading UK-based manufacturer of cranes and lifting equipment, including KBK crane systems. The company has a rich history in designing and manufacturing bespoke lifting solutions for various industries.

Key Features:

Custom design and manufacturing of KBK crane systems tailored to specific customer needs.

Expertise in both standard and bespoke crane solutions for diverse applications.

Comprehensive support, including installation, servicing, and maintenance.

Applications: Pelloby's KBK crane systems find applications in manufacturing, workshops, and warehouses across the UK.

Street Crane Company:

Overview: Street Crane Company is a well-established crane manufacturer with a strong presence in the UK and international markets. They specialize in producing a wide range of lifting solutions, including KBK crane systems.

Key Features:

Extensive experience in designing and manufacturing various types of cranes, including KBK systems.

High-quality components and robust construction for durability and reliability.

Innovation in crane technology to meet evolving industry needs.

Applications: Street Crane's KBK crane systems are used in manufacturing, logistics, and construction sectors in the UK.

When considering KBK crane manufacturers or suppliers in the United Kingdom, factors such as customization capabilities, industry expertise, and after-sales support are crucial for making an informed decision.

Canada

In Canada, several established KBK crane manufacturers and trusted suppliers contribute to the country's material handling industry. Here are notable companies in Canada's KBK crane sector:

Engineered Lifting Systems & Equipment Inc. (ELS):

Overview: ELS is a well-known Canadian company specializing in the design, manufacturing, and installation of lifting systems, including KBK crane solutions. With a focus on custom-engineered solutions, ELS serves a wide range of industries.

Key Features:

Expertise in providing customized KBK crane systems tailored to specific applications.

A commitment to quality, safety, and compliance with industry standards.

Comprehensive services, including installation, maintenance, and support.

Applications: ELS's KBK crane systems find applications in manufacturing, aerospace, and other industrial sectors across Canada.

Demag Cranes & Components Corp.:

Overview: Demag, a globally recognized name in crane technology, has a strong presence in Canada. The company offers a diverse range of lifting solutions, including KBK crane systems, designed to meet the needs of various industries.

Key Features:

Innovative and technologically advanced KBK crane systems for efficient material handling.

High-quality components and engineering for reliability and long-term performance.

Extensive support services, including maintenance and modernization options.

Applications: Demag's KBK crane systems are used in manufacturing, logistics, and distribution facilities across Canada.

When considering KBK crane manufacturers or suppliers in Canada, factors such as customization capabilities, industry experience, and adherence to safety standards should be taken into account for optimal material handling solutions.

India

In India, several prominent KBK crane manufacturers and reliable suppliers contribute to the country's diverse industrial landscape. Here are notable companies in India's KBK crane sector:

Bharat Bijlee Ltd.:

Overview: Bharat Bijlee is a well-established Indian company with expertise in providing a range of electric hoists and cranes, including KBK crane solutions. The company is known for its commitment to quality and innovation in material handling technology.

Key Features:

Comprehensive range of KBK crane systems catering to various load capacities.

Integration of advanced technologies for precision and efficiency in material handling.

Customization options to suit specific industrial applications.

Applications: Bharat Bijlee's KBK crane systems find applications in manufacturing, engineering, and construction sectors in India.

WMI Konecranes India:

Overview: WMI Konecranes is a part of the globally renowned Konecranes group and operates in India with a focus on providing lifting solutions, including KBK crane systems. The company is known for its commitment to safety, reliability, and sustainable solutions.

Key Features:

Diverse range of KBK crane systems designed for various industrial applications.

Emphasis on safety features and compliance with international standards.

Comprehensive service offerings, including installation, maintenance, and modernization.

Applications: WMI Konecranes' KBK crane systems are applied in manufacturing, warehousing, and logistics operations across India.

When evaluating KBK crane manufacturers or suppliers in India, factors such as product range, industry experience, and after-sales support should be considered to ensure the selection of a suitable and reliable solution.

Brazil

In Brazil, several noteworthy KBK crane manufacturers and reputed suppliers contribute to the country's material handling industry. Here are prominent companies in the Brazilian KBK crane sector:

GH Cranes & Components Brazil:

Overview: GH Cranes & Components is a global player with a presence in Brazil, offering a wide range of lifting solutions, including KBK crane systems. The company is known for its commitment to innovation, safety, and efficiency in material handling.

Key Features:

Comprehensive selection of KBK crane systems suitable for diverse applications.

Integration of advanced technologies for precise and reliable operations.

Customization options to meet specific industrial requirements.

Applications: GH Cranes & Components' KBK crane systems are utilized in manufacturing, construction, and logistics sectors in Brazil.

Demag Cranes & Components (Terex):

Overview: Demag, now part of the Terex Corporation, is a well-established brand offering a range of lifting and material handling solutions, including KBK crane systems. The company is recognized for its quality products and global presence.

Key Features:

Extensive portfolio of KBK crane systems designed for different load capacities.

Emphasis on safety features and compliance with international standards.

Robust construction for long-term performance and reliability.

Applications: Demag's KBK crane systems find applications in various industries, contributing to the efficiency of material handling processes in Brazil.

When considering KBK crane manufacturers or suppliers in Brazil, evaluating factors such as product quality, adherence to safety standards, and the ability to provide tailored solutions is crucial for making informed decisions.

South Korea

In South Korea, several major KBK crane manufacturers and reliable suppliers contribute to the country's material handling industry. Here are key players in the South Korean KBK crane sector:

Kukdong Hoist Co., Ltd.:

Overview: Kukdong Hoist is a major player in the South Korean crane industry, offering a diverse range of lifting solutions, including KBK crane systems. The company is known for its engineering expertise and commitment to delivering high-quality products.

Key Features:

Specialization in manufacturing various types of cranes, including KBK systems.

Customization options to meet specific industrial requirements.

Focus on innovation and technological advancements in crane design.

Applications: Kukdong Hoist's KBK crane systems are utilized in manufacturing, logistics, and other industries in South Korea.

Korea Crane Co., Ltd.:

Overview: Korea Crane is a reputable manufacturer providing a wide array of crane solutions, including KBK crane systems. The company is recognized for its reliable products and dedication to customer satisfaction.

Key Features:

Diverse range of KBK crane systems catering to different industrial needs.

Adherence to international safety and quality standards.

Ongoing commitment to research and development for improved crane technology.

Applications: Korea Crane's KBK crane systems are deployed in various sectors, contributing to efficient material handling in South Korea.

When evaluating KBK crane manufacturers or suppliers in South Korea, factors such as product quality, technological features, and the ability to customize solutions should be considered for optimal decision-making.

Australia

In Australia, the material handling industry benefits from leading KBK crane manufacturers and trusted suppliers. Here are key players in the Australian KBK crane sector:

Hoisting Equipment Specialists (HES):

Overview: HES is a leading provider of hoisting and lifting solutions, including KBK crane systems, in Australia. The company is recognized for its comprehensive range of products and commitment to safety and efficiency.

Key Features:

Extensive experience in the supply of KBK crane systems for various applications.

Customized solutions to meet specific lifting and handling requirements.

Emphasis on quality, compliance, and adherence to industry standards.

Applications: HES's KBK crane systems find applications in manufacturing, warehousing, and construction projects across Australia.

Konecranes Australia:

Overview: Konecranes is a globally renowned company with a significant presence in Australia. It offers a wide range of lifting equipment, including KBK crane systems, known for their reliability and advanced features.

Key Features:

Innovative and technologically advanced KBK crane solutions.

Comprehensive service and support network for clients.

Commitment to sustainability and safety in crane operations.

Applications: Konecranes' KBK crane systems are utilized in diverse industries, contributing to efficient and safe material handling in Australia.

When considering KBK crane manufacturers or suppliers in Australia, it's crucial to assess factors such as product reliability, after-sales support, and the ability to meet specific industry requirements.

Types of Light KBK Crane Systems

Single-Girder KBK Cranes

The single-girder KBK crane system is characterized by its simple yet robust design. It features a single horizontal beam, or girder, that supports the trolley and lifting mechanism. The design ensures optimal load distribution and facilitates smooth movement along the KBK Rail System.

Ceiling-Mounted vs. Freestanding Crane Design:

Ceiling-Mounted Design:In this configuration, the single-girder KBK crane is attached to the ceiling structure, maximizing floor space. This is ideal for facilities where floor space is at a premium, allowing unobstructed movement below the crane.

Freestanding Design:Freestanding single-girder KBK cranes are supported by their own structure, eliminating the need for attachment to the ceiling. This design provides flexibility in installation and is suitable for facilities with specific layout requirements or limitations in ceiling structure support.

Double-Girder KBK Cranes

Double-girder KBK cranes, distinguished by two horizontal girders supporting the trolley and lifting mechanism, are engineered for enhanced load capacities. This design allows these cranes to handle heavier loads compared to their single-girder counterparts. The increased load capacity makes them well-suited for applications demanding robust lifting capabilities.

Superior Stability and Precision

Ceiling-Mounted vs. Freestanding Crane Design:

Articulated KBK Cranes

Articulated KBK cranes, known for their versatility, feature an articulated girder that allows for increased flexibility in movement. This unique design enables the crane to navigate around obstacles, reach confined spaces, and perform intricate maneuvers, making it a valuable asset in settings with dynamic material handling requirements.

Ceiling-Mounted vs. Freestanding Crane Design:

Monorail KBK Crane Systems

Efficient Linear Movement

Monorail KBK crane systems are characterized by a single rail, offering efficient linear movement along a defined path. The design ensures a streamlined and predictable trajectory for the trolley and lifting mechanism. This configuration is particularly effective for tasks that involve moving loads along a specific route within a facility.

KBK Rails

Structure and Composition

KBK rails form the backbone of the entire Light KBK Crane system, providing the essential structure for the trolley and hoisting mechanisms. These rails are typically made from high-strength materials, ensuring durability and load-bearing capacity. The modular design of KBK rails allows for easy installation and customization.

Types of KBK Rails

- Straight Rails:Standard straight rails provide a linear path for the trolley and hoisting mechanisms, offering simplicity in design and operation.

- Curved Rails:Curved KBK rails allow for changes in direction, enabling the crane to navigate around obstacles or follow a specific layout within a facility.

- Switches and Intersections:KBK rail systems often include switches and intersections, facilitating the creation of complex layouts and providing flexibility in material handling routes.

KBK rails and mounted devices for light kbk crane systems

Enclosed kbk rails to have the trolley travelling inside to ensure smooth travelling in dusty workshops or facilities or in clean rooms

Trolleys

Trolleys are the components that move along the KBK rails, supporting the hoisting mechanism and the load. Different types of trolleys cater to specific load capacities, movement requirements, and functionalities:

- Manual Trolleys:Operated by manual force, these trolleys are suitable for lighter loads and applications where precise control is necessary.

- Electric Trolleys:Powered by electric motors, these trolleys offer automated movement, enhancing efficiency in material handling processes.

The kbk hoist trolley can be manual travelling for lighter loads handing

Electric trolley for quick and high efficiency workstation kbk cranes

Types of KBK Crane Hoists

KBK crane hoists are responsible for lifting and lowering the load. Different types of hoists are available to accommodate various load capacities and operational needs:

- Electric Chain Hoists:Commonly used for medium to heavy loads, electric chain hoists offer efficient and controlled lifting.

- Wire Rope Hoists:Suitable for heavier loads and more demanding applications, wire rope hoists provide robust lifting solutions.

- Air Hoists:Utilizing compressed air for operation, air hoists are often preferred in environments where electricity may not be suitable.

European style light electric hoist for kbk crane system with pendant control or remote control

Light kbk crane with electric chain hoist , which can be designed with low headroom design and explosion proof hoist design

Typical KBK Crane Manufacturing Standards, Standard KBK Crane Designs

Germany

Manufacturing Standards:

German KBK crane manufacturers adhere to rigorous engineering and safety standards set by organizations such as DIN (Deutsches Institut für Normung - German Institute for Standardization).

Compliance with ISO standards ensures the quality and safety of KBK crane systems.

Standard KBK Crane Designs:

Germany offers diverse KBK crane designs to cater to different industrial needs.

Single-girder, double-girder, and articulated KBK cranes are among the standard designs available.

Key Features and Innovations:

Precision Control: German KBK cranes are known for their precision in load handling, allowing for meticulous control in manufacturing processes.

Advanced Automation: Integration of advanced automation features enhances efficiency and reduces manual intervention.

Seamless Integration: KBK cranes seamlessly integrate into complex manufacturing processes, providing a streamlined material handling solution.

Typical Applications:

Automotive Manufacturing: KBK cranes are extensively used on automotive assembly lines for the precise handling of components.

Precision Engineering: In precision engineering, KBK cranes play a crucial role in handling delicate parts with accuracy.

High-Tech Industries: The high-tech sector benefits from KBK cranes' ability to meet the stringent demands of advanced manufacturing processes.

Price Range:

German KBK cranes are positioned in the premium pricing segment.

The higher cost reflects the engineering excellence, advanced features, and precision control offered by these systems.

Exporting Countries:

Germany is a major exporter of KBK cranes, supplying these high-quality systems to various countries across the globe.

Export destinations include both developed and emerging industrial markets where the demand for advanced material handling solutions is significant.

United States

Manufacturing Standards:

KBK crane manufacturers in the United States strictly adhere to stringent safety and quality regulations set by organizations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute).

Compliance with these standards ensures the reliability and safety of KBK crane systems.

Standard KBK Crane Designs:

The United States offers versatile KBK crane designs to cater to a wide range of industrial applications.

These designs are adaptable to various industries, making them suitable for diverse material handling needs.

Key Features and Innovations:

Incorporation of Advanced Technology: U.S.-manufactured KBK cranes are equipped with advanced technological features to enhance efficiency in material handling operations.

Efficient Material Handling: The focus is on providing solutions that contribute to streamlined and efficient material handling processes.

Typical Applications:

Manufacturing: KBK cranes are commonly used in manufacturing facilities for the handling of materials and components.

Warehousing: In warehouse environments, KBK cranes play a pivotal role in optimizing storage and retrieval processes.

Construction: KBK cranes find applications in construction sites for efficient material transport and positioning.

Price Range:

The pricing of KBK cranes in the United States varies based on specific features, configurations, and capacities.

Customers can choose from a range of options that align with their budget and application requirements.

Exporting Countries:

U.S.-manufactured KBK cranes are exported to global markets, contributing to the international demand for reliable and technologically advanced material handling solutions.

China

Manufacturing Standards:

Chinese KBK crane manufacturers adhere to both domestic and international manufacturing standards. They ensure the production of high-quality and compliant crane systems.

The adherence to international standards facilitates the export of Chinese KBK cranes to various global markets.

Standard KBK Crane Designs:

China offers a diverse range of KBK crane designs to cater to different industrial requirements. This includes configurations with single and double-girder setups.

The flexibility in designs allows Chinese KBK cranes to be suitable for various applications across industries.

Key Features and Innovations:

Cost-Effective Solutions: Chinese KBK cranes are known for providing cost-effective material handling solutions without compromising on quality.

Adaptable Designs: The designs of KBK cranes from China are adaptable to different operational needs, making them versatile for various industries.

Advanced Technology: Incorporation of advanced technological features ensures efficiency and reliability in material handling processes.

Typical Applications:

Chinese KBK cranes are widely used in China's thriving manufacturing sector, including applications in the automotive and electronics industries.

Their adaptability and cost-effectiveness make them suitable for various material handling tasks within industrial facilities.

Price Range:

Chinese KBK cranes are competitively priced due to lower manufacturing costs, making them an attractive option for businesses seeking efficient material handling solutions.

Exporting Countries:

Chinese KBK crane manufacturers actively export their products globally, contributing to the international market for material handling equipment.

Japan

Manufacturing Standards:

Japanese KBK crane manufacturers adhere to high engineering standards, ensuring the production of precision equipment with a focus on safety and quality.

The commitment to these standards reflects the meticulous engineering processes involved in manufacturing KBK cranes in Japan.

Standard KBK Crane Designs:

Japanese KBK cranes often feature specialized designs tailored for precision handling, especially in industries like electronics.

The designs prioritize precision control and are well-suited for applications requiring delicate parts handling.

Key Features and Innovations:

Emphasis on Precision Control: Japanese KBK cranes place a significant emphasis on precision control, making them suitable for applications that require meticulous handling of components.

Innovative Technologies: Incorporation of innovative technologies ensures that Japanese KBK cranes remain at the forefront of advanced material handling solutions.

Typical Applications:

Japanese KBK cranes find significant use in the electronics industry, where precision handling of delicate parts is crucial. Their specialized designs make them well-suited for such applications.

Price Range:

Japanese KBK cranes are positioned at a premium price range, reflecting the advanced features, precision engineering, and technological innovations incorporated into their design.

Exporting Countries:

Japanese KBK crane manufacturers export their products to countries with advanced manufacturing sectors, seeking high-precision material handling solutions.

United Kingdom

Manufacturing Standards:

KBK crane manufacturers in the United Kingdom adhere to stringent safety and quality standards set by UK regulations. This ensures that the manufactured cranes meet the required safety benchmarks and quality criteria.

Standard KBK Crane Designs:

The designs of KBK cranes in the UK are adaptable, catering to various industrial settings. This adaptability allows for the customization of crane systems to suit the specific needs of different industries.

Key Features and Innovations:

Emphasis on Safety and Efficiency: KBK crane designs from the UK often prioritize safety features to ensure the well-being of workers and the efficiency of material handling processes.

Typical Applications:

UK-manufactured KBK cranes are commonly used in manufacturing, warehousing, and construction activities. Their adaptable designs make them suitable for diverse applications within these sectors.

Price Range:

The pricing of KBK cranes in the United Kingdom is generally moderate, reflecting the balance between features and cost. It offers a cost-effective solution for various industrial applications.

Exporting Countries:

UK-manufactured KBK cranes may be exported to specific markets, depending on the business strategies and global demand for their crane systems.

Canada

Manufacturing Standards:

Canadian KBK crane manufacturers adhere to rigorous safety and quality regulations set by Canadian authorities. This ensures that the cranes meet the required standards for safe and efficient operations.

Standard KBK Crane Designs:

The designs of KBK cranes in Canada are robust, specifically tailored for challenging environments. These designs ensure the durability and reliability of the crane systems, making them suitable for various industrial applications.

Key Features and Innovations:

Cold-Weather Adaptations: Given Canada's diverse climates, KBK crane designs in Canada may incorporate features that adapt to cold weather conditions. This ensures optimal performance even in challenging environments.

Typical Applications:

KBK cranes in Canada find applications in automotive manufacturing and resource extraction. Their robust designs make them suitable for handling heavy loads and operating in demanding industrial settings.

Price Range:

The pricing of KBK cranes in Canada varies based on configurations and specific features incorporated into the crane systems. The pricing reflects the quality and capabilities of the cranes.

Exporting Countries:

Canadian KBK crane manufacturers may consider exporting their crane systems to neighboring markets, depending on the demand and business strategies.

India

Manufacturing Standards:

Indian KBK crane manufacturers adhere to the safety and quality standards set by Indian regulatory authorities. This ensures that the manufacturing processes and the final products meet the required standards for safe and efficient operations.

Standard KBK Crane Designs:

KBK crane designs in India are versatile, catering to diverse industrial applications. These designs are adaptable and can be customized to suit the specific requirements of different industries.

Key Features and Innovations:

Cost-Effective Solutions: Indian KBK crane designs often focus on providing cost-effective solutions, making them suitable for emerging markets. The emphasis is on delivering reliable performance at competitive prices.

Typical Applications:

KBK cranes in India find applications in manufacturing facilities and construction. Their versatile designs make them suitable for various material handling tasks in different industrial settings.

Price Range:

The pricing of KBK cranes in India is competitive, reflecting the lower manufacturing costs in the country. This affordability makes them accessible to a wide range of industries.

Exporting Countries:

Indian KBK crane manufacturers may consider exporting their crane systems to neighboring countries based on market demand and business strategies.

Brazil

Manufacturing Standards:

Brazilian KBK crane manufacturers conform to the safety and quality regulations set by Brazilian authorities. This ensures that the manufacturing processes and the final products meet the required standards for safe and efficient operations in the country.

Standard KBK Crane Designs:

KBK crane designs in Brazil are characterized by their sturdy construction, making them suitable for challenging industrial applications. These designs are built to withstand heavy loads in demanding environments.

Key Features and Innovations:

Heavy-Load Capacity: Brazilian KBK crane designs often emphasize heavy-load capacity, catering to the needs of industries such as automotive and mining where substantial material handling capabilities are essential.

Typical Applications:

KBK cranes in Brazil find applications in the automotive and mining industries. Their robust designs make them well-suited for handling heavy loads in these industrial settings.

Price Range:

The pricing of KBK cranes in Brazil can vary based on specifications and requirements. The pricing structure reflects the features and capacities designed to meet the demands of specific applications.

Exporting Countries:

Brazilian KBK crane manufacturers may consider exporting their crane systems to neighboring countries, depending on market demand and business strategies.

Australia

Manufacturing Standards: Adheres to rigorous Australian safety and quality standards, ensuring compliance with the country's industrial regulations.

Standard KBK Crane Designs: Australian KBK cranes are designed to be adaptable, catering to various industrial settings. The designs are versatile and can be customized based on specific requirements.

Key Features and Innovations: The emphasis is on compliance with Australian safety and quality standards, ensuring that the KBK cranes meet the stringent requirements of the industry. Advanced features may include automation capabilities, efficient material handling, and durability to withstand challenging environments.

Typical Applications: KBK cranes in Australia find applications in diverse sectors, including mining, manufacturing, and various industrial facilities. The adaptable design allows these cranes to handle a range of materials and tasks efficiently.

Price Range: The pricing for Australian KBK cranes is generally moderate, reflecting the competitive market. Prices may vary based on specific features, configurations, and customization options.

Exporting Countries: While Australian KBK crane manufacturers may primarily serve the domestic market, there could be opportunities for exporting to specific markets where Australian engineering and quality standards are recognized and valued.

Comparisons of KBK Crane Markets Worldwide

Designs and Quality

Evaluating Design Innovations

In the global KBK crane market, designs play a pivotal role in meeting diverse industrial needs. Manufacturers worldwide strive for innovation to enhance crane functionality, efficiency, and adaptability. Evaluating design innovations involves looking at:

- Modularity: How well the KBK crane systems can be adapted and expanded based on the evolving needs of different industries.

- Automation Integration: The level of automation and smart features incorporated to streamline material handling processes.

- Adaptability: How easily the crane systems can be customized to fit into different work environments and handle various loads.

- Specialized Designs: Assessing whether manufacturers offer specialized designs catering to specific industries such as automotive, electronics, or heavy manufacturing.

Assessing the Quality Standards

Quality is a critical factor influencing the reliability and longevity of KBK crane systems. Manufacturers worldwide adhere to different quality standards, and assessing these standards involves:

- Compliance: Ensuring that the KBK crane systems comply with relevant safety and engineering standards in the regions they are intended for use.

- Material Quality: Evaluating the materials used in construction to determine durability and resistance to environmental factors.

- Certifications: Checking for certifications and compliance with international quality management systems, ensuring a commitment to consistent quality.

- User Feedback: Considering user reviews and feedback on the performance and longevity of KBK crane systems in real-world industrial applications.

By evaluating design innovations and assessing the quality standards of KBK crane systems globally, potential buyers can make informed decisions based on their specific industrial requirements and preferences.

Price and Affordability

Comparing Price Ranges

Price is a crucial consideration for buyers, and the KBK crane market exhibits variations in pricing based on factors like brand reputation, features, and manufacturing costs. When comparing price ranges:

- Budget Considerations: Understanding the budget constraints and finding KBK crane solutions that offer the best value for the investment.

- Total Cost of Ownership: Considering not just the initial purchase price but also the long-term costs associated with maintenance, upgrades, and operational efficiency.

- Comparing Features: Weighing the features offered by different manufacturers against their respective price points to ensure a cost-effective solution.

Balancing Cost with Quality

While affordability is important, it should not come at the expense of quality. Balancing cost with quality involves:

- Identifying Value: Assessing the overall value proposition, which includes both the cost and the quality of the KBK crane system.

- Long-Term Benefits: Considering the long-term benefits and operational efficiency gained from a high-quality KBK crane system.

- Customization Options: Exploring whether manufacturers offer customization options that align with specific industrial requirements.

Industry Focus and Specialization

Identifying Industry-Specific Expertise

Different industries have unique material handling needs, and KBK crane manufacturers often specialize in catering to specific sectors. When identifying industry-specific expertise:

- Understanding Industry Needs: Evaluating whether manufacturers have a deep understanding of the material handling requirements in a particular industry.

- Custom Solutions: Checking if manufacturers offer custom solutions tailored to the demands of specific sectors.

Choosing Suppliers with Specialized Offerings

Choosing suppliers with specialized offerings involves:

- Researching Product Range: Exploring the range of KBK crane systems offered by a supplier to determine if they have specialized solutions for specific applications.

- Supplier Reputation: Considering the reputation of suppliers in delivering specialized KBK crane systems that meet industry-specific challenges.

Customer Reviews and Testimonials

Analyzing Customer Satisfaction

Customer reviews and testimonials provide valuable insights into the real-world performance of KBK crane systems. When analyzing customer satisfaction:

- Reliability: Evaluating feedback on the reliability and durability of the crane systems in actual working environments.

- After-Sales Support: Considering customer reviews related to after-sales support, maintenance services, and response times.

By comparing price and affordability, understanding industry focus and specialization, and analyzing customer reviews and testimonials, buyers can make informed decisions that align with their budget, industry requirements, and expectations for product quality and support.

| Country | Manufacturing Standards | Standard KBK Crane Designs | Key Features and Innovations | Typical Applications | Price Range | Exporting Countries |

|---|---|---|---|---|---|---|

| Germany | Compliant with strict German engineering and safety standards. | Diverse designs, including single-girder, double-girder, and articulated KBK cranes. | Precision control, advanced automation, and seamless integration into complex manufacturing processes. | Widely used in automotive manufacturing, precision engineering, and high-tech industries. | Premium pricing due to high-quality engineering and advanced features. | Globally |

| United States | Adheres to stringent U.S. safety and quality regulations. | Versatile designs suitable for diverse industrial applications. | Incorporates advanced technology for efficient material handling. | Commonly used in manufacturing, warehousing, and construction. | Varied pricing based on features and configurations. | Global markets |

| China | Meets both domestic and international standards. | Diverse designs catering to different industries, including single and double-girder configurations. | Cost-effective solutions, adaptable designs, and advanced technology. | Widely used in China's booming manufacturing sector, including automotive and electronics. | Competitive pricing due to lower manufacturing costs. | Global |

| Japan | Conforms to high Japanese engineering standards. | Specialized designs for precision handling in industries like electronics. | Emphasis on precision control and innovative technologies. | Mainly used in the electronics industry for delicate parts handling. | Premium pricing for advanced features. | Exports to countries with advanced manufacturing sectors. |

| United Kingdom | Complies with stringent UK safety and quality standards. | Adaptable designs for various industrial settings. | Emphasis on safety and efficiency. | Used in manufacturing, warehousing, and construction activities. | Moderate pricing based on features. | May be exported to specific markets |

| Canada | Adheres to Canadian safety and quality regulations. | Robust designs suitable for challenging environments. | Cold-weather adaptations for Canadian climates. | Utilized in automotive manufacturing and resource extraction. | Varied pricing based on configurations. | May export to neighboring markets |

| India | Complies with Indian safety and quality standards. | Versatile designs suitable for diverse industries. | Cost-effective solutions tailored for emerging markets. | Used in manufacturing facilities and construction. | Competitive pricing due to lower manufacturing costs. | May export to neighboring countries |

| Brazil | Conforms to Brazilian safety and quality regulations. | Sturdy designs for industrial applications. | Heavy-load capacity for demanding environments. | Utilized in automotive and mining industries. | Varied pricing based on specifications. | May export to neighboring countries |

| South Korea | Meets South Korean safety and quality standards. | Advanced designs for precision handling. | Integration with South Korea's advanced manufacturing technologies. | Commonly used in electronics manufacturing and automotive industries. | Competitive pricing with advanced features. | Exports globally |

| Australia | Adheres to Australian safety and quality standards. | Adaptable designs for various industrial settings. | Compliance with Australian safety and quality standards. | Utilized in mining, manufacturing, and industrial facilities. | Moderate pricing based on features. | May export to specific markets |

This table provides a comparative overview of KBK crane manufacturers and suppliers in different countries, considering manufacturing standards, crane designs, key features, typical applications, price range, and exporting countries.

Top KBK Crane Manufacturers and Suppliers Worldwide

Leading Global KBK Crane Manufacturers

DEMAG Cranes:

Overview: A global supplier of industrial cranes and components.

Expertise: Known for providing high-quality KBK crane systems.

Global Reach: Serves various industries with a global presence.

ABUS Kransysteme:

Overview: Germany-based company specializing in hoists and crane systems.

Product Range: Offers a variety of crane solutions, including KBK systems.

German Engineering: Known for precision and quality in engineering.

STAHL CraneSystems:

Overview: A leading German manufacturer of hoists and crane technology.

Product Line: Specializes in various lifting solutions, including KBK crane systems.

Quality Assurance: Recognized for adherence to high-quality standards.

Konecranes:

Overview: Global leader in lifting equipment and crane solutions.

Diverse Offerings: Provides a wide range of crane solutions, including KBK systems.

Innovation: Emphasizes advanced technology and innovation.

Gorbel:

Overview: U.S.-based manufacturer known for ergonomic lifting solutions.

Product Line: Offers various crane and material handling solutions, including KBK systems.

Focus on Ergonomics: Recognized for solutions prioritizing user comfort and safety.

Spanco:

Overview: U.S.-based company providing crane and material handling solutions.

Product Range: Offers a diverse range of solutions, including KBK crane systems.

Customization: Known for providing customized solutions based on customer needs.

KITO Corporation:

Overview: Japanese company specializing in hoists and cranes.

Product Portfolio: Offers a variety of lifting solutions, including KBK systems.

Japanese Precision: Known for precision engineering and reliability.

Street Crane Company:

Overview: UK-based company specializing in overhead crane systems.

Product Focus: Designs and produces a range of crane solutions, including KBK systems.

British Engineering: Known for quality engineering and safety standards.

GH Cranes & Components:

Overview: Spanish company offering a variety of lifting solutions.

Product Line: Provides diverse lifting solutions, including KBK crane systems.

Global Presence: Serves customers internationally.

Columbus McKinnon Corporation:

Overview: U.S.-based global player in material handling solutions.

Product Range: Offers a comprehensive range of material handling solutions, including KBK crane systems.

International Presence: Distributes products globally with a strong network.

These companies collectively contribute to the global KBK crane industry, offering a diverse range of solutions tailored to meet the specific needs of various industries.

How to Choose Your KBK Crane Manufacturer and Supplier

Assessing Specific Application Needs

Understanding Requirements: Identify the specific needs and challenges of your application.

Capacity and Span: Assess load capacities, required spans, and other critical factors.

Environment Considerations: Consider the operating environment, such as temperature, humidity, and potential hazards.

Requesting Customization Options

Custom Solutions: Inquire about the manufacturer's ability to provide customized KBK crane systems.

Adaptability: Ensure the systems can be tailored to match the unique demands of your operations.

Modularity: Check if the systems can be easily expanded or modified to accommodate future changes.

Evaluating After-Sales Support and Services

Maintenance Services: Inquire about the availability of maintenance and servicing packages.

Response Time: Assess the manufacturer's response time for addressing issues or providing technical support.

Training Programs: Check if the supplier offers training programs for operators and maintenance personnel.

Checking Industry Certifications and Compliance

Quality Standards: Ensure the manufacturer complies with relevant quality standards in the industry.

Safety Certifications: Verify that the KBK crane systems adhere to international safety standards.

Environmental Compliance: Check if the systems meet environmental regulations and standards.

Choosing the right KBK crane manufacturer and supplier involves a thorough assessment of your specific needs, ensuring that the selected systems align with your application requirements. Additionally, considering factors like customization options, after-sales support, and adherence to industry standards will contribute to a successful and efficient material handling solution.

Conclusion

Summarizing Key Considerations

On selecting the right KBK crane manufacturer and supplier, several key considerations play a pivotal role. Assessing your specific application needs, seeking customization options, evaluating after-sales support, and ensuring compliance with industry standards are crucial steps in making an informed decision.

Understanding the unique demands of your operations, whether it's in terms of load capacities, environmental conditions, or adaptability, ensures that the chosen KBK crane system aligns seamlessly with your requirements. Customization options, modularity, and the ability to cater to future changes contribute to the long-term efficiency and effectiveness of the crane systems.

Evaluating after-sales support and services is equally vital. Availability of maintenance packages, responsive customer support, and comprehensive training programs contribute to the smooth operation and longevity of the KBK crane systems.

Lastly, checking industry certifications and compliance ensures that the selected KBK crane systems meet the highest standards of quality, safety, and environmental responsibility.

Encouraging Informed Decision-Making for KBK Crane Selection

When selecting a KBK crane manufacturer and supplier, we encourage a meticulous and informed decision-making process. By considering the outlined factors and engaging in thorough discussions with potential suppliers, you pave the way for a successful partnership that enhances your material handling capabilities.

Remember that the right KBK crane system goes beyond being a piece of equipment; it becomes a tailored solution that contributes to the efficiency, safety, and overall success of your operations. We wish you success in finding the perfect KBK crane system that aligns with your unique needs and contributes to the seamless flow of your material handling processes.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch