Single Girder Gantry Crane for Sale – Types & Customization

1 to 20 ton single girder gantry crane for sale. Affordable gantry cranes, customizable spans, electric hoists & controls for various industries.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Single Girder Gantry Cranes for Sale – Types and Customization

1 to 20 ton single girder gantry crane for sale. Affordable gantry cranes for sale, hot sale single beam gantry crane types, and customized solutions, customizable spans, for various industries.

Single Girder Gantry Crane for Sale

Single girder gantry cranes are a common and practical solution for lifting and moving loads in many industries. They consist of a single beam (the girder) supported by legs that move on wheels or rails, making them perfect for outdoor and indoor use. You often find these cranes in workshops, warehouses, and construction sites where space and budget are limited but reliable lifting is still essential.

Why are single girder gantry cranes so popular? For one, they are simpler in design compared to double girder cranes, which means they are usually more affordable and easier to maintain. They work well for medium and light loads, typically ranging from half a ton to 20 tons, depending on the model and customization. Their flexibility allows them to fit various spaces and handle different types of materials safely and efficiently.

In the fast-moving world of material handling, having the right crane can make a big difference. Single girder gantry cranes help businesses improve workflow by reducing manual labor and speeding up load transfers. Whether you're lifting steel coils, machinery parts, or construction materials, these cranes provide a dependable way to move heavy items with less hassle.

This article will walk you through the main types of single girder gantry cranes, their typical uses, and how you can customize them to fit your specific needs. If you're considering buying or upgrading a crane, understanding these basics will help you make a better, more informed choice.

Basics of Single Girder Gantry Cranes

At its core, a single girder gantry crane is a type of overhead crane that uses one main horizontal beam, or girder, to carry the hoist and move loads. The girder is supported by two legs, which usually have wheels that run along ground rails or tracks. This setup allows the crane to move back and forth, carrying loads across an open area without needing a fixed overhead runway.

Key Components of a Single Girder Gantry Crane

- Girder: The single main beam that spans the width of the crane and supports the hoist.

- Legs: Vertical supports attached to the girder, equipped with wheels for movement.

- Hoist: The lifting device mounted on the girder, which can be electric wire rope, chain, or manual.

- Wheels and Rails: Enable the crane to roll along a fixed path for horizontal movement.

- Control System: Usually pendant control or remote control to operate the crane safely.

How Single Girder Gantry Cranes Differ from Double Girder and Other Types

Unlike double girder gantry cranes, which have two parallel girders to support heavier loads and longer spans, single girder cranes use only one girder. This difference makes single girder cranes lighter and less expensive but limits their capacity and span length. For most light to medium tasks, a single girder crane is enough and often more practical.

Another key difference is in the hoist design. On single girder cranes, the hoist usually runs on the lower flange of the girder, which keeps the crane's overall height lower. Double girder cranes allow for bigger hoists that can lift heavier loads and cover wider areas, but at the cost of increased weight and price.

Basic Working Principle

A single girder gantry crane moves loads in three main ways:

- Lifting and lowering: The hoist raises and lowers the load vertically.

- Longitudinal movement: The hoist trolley moves along the girder to position the load anywhere along the crane's span.

- Crane travel: The entire crane moves horizontally along rails on the ground, covering the length of the workspace.

Together, these movements allow precise handling of materials across a large area, with minimal manual effort. The operator controls the crane either by a pendant button or a remote control, ensuring safe and efficient operation.

Types of Single Girder Gantry Cranes

European Style Single Girder Gantry Cranes come in various types, each suited for different lifting tasks and work environments. Knowing the options helps you pick the right crane for your specific needs.

Standard Single Girder Gantry Cranes

These are the most widely used type. They have two legs and a single main beam, designed to move on rails installed on the ground.

Light-Duty Models:

These cranes typically handle loads up to 5 tons. They are great for small workshops, assembly lines, or warehouses where loads are lighter and frequent movement is required.

- Compact design fits limited spaces

- Simple control systems for easy operation

- Lower cost and easier installation

Medium-Duty Models:

Handling capacities usually range from 5 to 20 tons. These are suitable for larger manufacturing plants, outdoor yards, and construction sites where heavier loads are common.

- More robust construction

- Can cover wider spans and higher lifting heights

- Equipped with stronger hoists and control options

Desing Options of Standard Single Girder Gantry Crane for Sale

No cantielver single girder gantry crane

Double cantilever single girder gantry crane for sale

single cantilever single girer gantry crane for sale

Outdoor gantry crane single girder with high wind resistant capability

Semi-Gantry Cranes single Girder for Sale (One Leg on Ground, One on Runway)

Semi-gantry cranes are a hybrid design where one leg of the crane moves on ground rails, and the other side runs on an elevated runway beam. This design is useful when one side of the workspace is obstructed or when existing structures limit full gantry movement.

- Saves space on one side of the work area

- Ideal for loading docks or near walls

- Offers stability with less rail installation

Portable or Mobile Single Girder Gantry Cranes

These 10 ton portable gantry cranes come with wheels that run directly on the floor without fixed rails. They are easy to move around the shop or yard and are perfect for temporary lifting tasks.

- Easy to reposition without complex installation

- Capacity usually up to 3 tons

- Common in maintenance, repair shops, and small factories

Single Girder Rubber Tyred Gantry Cranes

These mobile gantry cranes are equipped with rubber tyres for flexible movement across uneven or paved surfaces, without the need for tracks. Ideal for outdoor or large-yard operations.

- No track installation required

- Typically handles 5–20 tons

- Used in precast yards, fabrication plants, and outdoor storage areas

Specialized Models

- Low-Headroom Cranes:

Designed for places with limited vertical space, these cranes have a compact girder and hoist setup to maximize lifting height while minimizing the crane's own height. - Outdoor Weather-Resistant Cranes:

Built with protective coatings and materials to withstand rain, wind, and corrosion. Suitable for construction sites, shipping yards, and other outdoor environments. - Explosion-Proof Models:

For use in hazardous environments like chemical plants or oil refineries, these cranes are designed with special electrical components to prevent sparks and ensure safety.

Comparison Table of Common Models

| Model Type | Capacity Range | Typical Span (m) | Key Features | Typical Use Cases |

|---|---|---|---|---|

| Light-Duty Standard | 0.5 – 5 tons | 5 – 15 | Compact, simple controls | Small workshops, warehouses |

| Medium-Duty Standard | 5 – 20 tons | 10 – 30 | Robust build, stronger hoists | Manufacturing plants, yards |

| Semi-Gantry | 1 – 15 tons | 8 – 25 | One leg on ground, one on runway | Loading docks, limited space |

| Portable/Mobile | 0.5 – 3 tons | Variable | Wheels on floor, easy movement | Maintenance, repair, light jobs |

| Low-Headroom | Up to 10 tons | Variable | Compact height design | Low clearance workshops |

| Outdoor Weather-Resistant | Up to 20 tons | Variable | Corrosion protection, sealed parts | Construction, shipping yards |

Typical Uses and Applications

Single girder gantry cranes are versatile machines used in a variety of settings. Their simplicity and cost-effectiveness make them a go-to choice for many industries that need reliable lifting without the expense or complexity of larger cranes.

Workshops and Small Manufacturing Plants

In small to medium-sized workshops, single girder gantry cranes help move heavy parts, tools, and equipment with ease. They improve workflow by allowing workers to lift and position materials quickly, reducing manual effort and injury risk.

- Ideal for assembly lines and repair shops

- Handles parts like machine components, molds, and fabricated steel

- Fits limited ceiling height and floor space

Loading and Unloading in Warehouses

Many warehouses use these cranes to load and unload goods from trucks or stack heavy items in storage. Their mobility on rails or wheels allows flexible operation along docks or storage aisles.

- Speeds up loading/unloading processes

- Moves bulky items like pallets, crates, or packaged machinery

- Can be customized with portable designs for temporary use

Construction Sites and Outdoor Operations

On construction sites, where ground conditions and space vary, portable or semi-gantry single girder cranes provide essential lifting support. They assist in moving materials such as steel beams, concrete blocks, and construction equipment.

- Easy to relocate as project needs change

- Weather-resistant models available for outdoor use

- Helps in assembling structural components on site

Shipyards and Ports (Small-Scale Handling)

While large ports use heavy-duty cranes, single girder gantry cranes serve well in smaller shipyards or docks where lighter loads need moving. They assist with lifting ship parts, containers, or repair materials.

- Useful for maintenance and small cargo handling

- Can operate in tight spaces with limited headroom

- Often paired with weatherproof or corrosion-resistant features

Other Industry-Specific Applications

Different industries find single girder gantry cranes handy for unique tasks:

- Automotive plants: Moving engines, chassis, and tooling

- Plastics manufacturing: Handling molds, raw materials, and finished products

- Metal fabrication: Positioning sheets, plates, and smaller assemblies

- Agriculture: Loading heavy equipment and supplies

In all these applications, the key benefit is reliable, flexible lifting without the need for heavy infrastructure or large capital investment.

Key Factors in Choosing a Single Girder Gantry Crane

Choosing the right single girder gantry crane involves more than just picking a model off the shelf. You need to consider several important factors to ensure your crane fits your operation safely and efficiently.

Load Capacity and Safety Factors

The first step is determining the maximum weight you need to lift regularly. Don't just think about your heaviest load — always add a safety margin, typically 10% to 25%, to cover unexpected conditions or future increases.

- Confirm the crane's rated capacity meets or exceeds your maximum load plus safety margin

- Check for compliance with relevant safety standards and certifications

- Consider dynamic loads, like swinging or sudden stops, which can increase stress on the crane

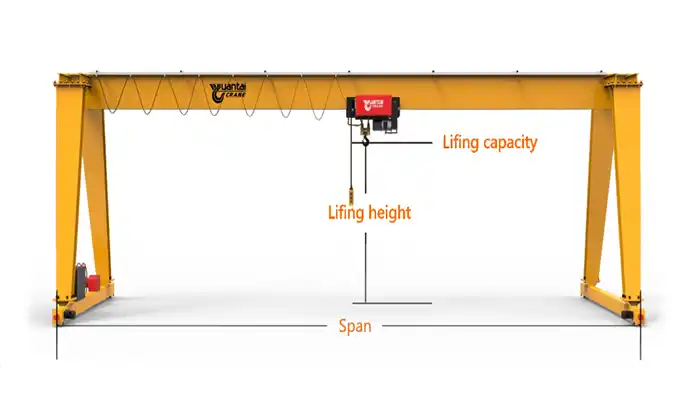

Span and Working Area Requirements

Span refers to the distance between the crane's legs or rails, essentially how wide the crane can cover. Make sure the crane's span matches your workspace and the area you need to reach.

- Measure your workshop or yard width accurately

- Think about any obstructions that may limit crane movement

- Plan for enough clearance around the crane for safe operation

Duty Classification (Frequency and Duration of Use)

Duty classification defines how often and how intensively the crane will be used. This affects the crane's design and components durability.

- Light-duty cranes work well for occasional lifting or short shifts

- Medium to heavy-duty cranes are necessary for continuous or heavy-cycle operations

- Consult standards like ISO or CMAA for duty classification guidelines

Environment (Indoor/Outdoor, Corrosive, Dusty)

The environment where the crane operates has a big impact on its design and materials. For example, outdoor cranes need protection against weather, while dusty or corrosive environments require special coatings and sealed components.

- Indoor cranes may have simpler paint finishes and less weatherproofing

- Outdoor cranes should have corrosion-resistant paint, covers, and sealed electrical parts

- Hazardous environments might require explosion-proof cranes and extra safety features

Power Supply and Control Options

Consider your site's power availability and the preferred control method for the crane. Different cranes support various voltages and control styles.

- Check voltage and phase compatibility with local power supply

- Choose between pendant control, wireless remote control, or cabin operation depending on your needs

- Evaluate if power backup or energy-efficient options are needed

Taking time to evaluate these factors carefully will save you headaches later, ensuring the crane you buy fits your operation's needs and budget perfectly.

Customization Options for Single Girder Gantry Cranes

Every workspace is different, and a one-size-fits-all crane doesn't always work. Luckily, single girder gantry cranes offer plenty of customization options to fit your exact needs and working conditions.

Customized Span and Height for Specific Workspace

The span (distance between crane legs) and height can be tailored to match your workshop or yard dimensions precisely. This ensures the crane covers the full working area without wasting space or risking collisions.

- Adjust span to fit narrow or wide aisles

- Modify lifting height to clear obstacles or fit under ceilings

- Design crane dimensions to match your existing infrastructure

Hoist Types and Capacities

The hoist is the heart of the crane, and you can choose from several types depending on load, precision, and budget:

- Electric Wire Rope Hoists: Best for heavier loads and smooth lifting with good speed control

- Chain Hoists: More compact, ideal for lighter loads and simple applications

- Manual Hoists: Used for very light loads or occasional lifting, cost-effective but labor-intensive

You can also specify the exact lifting capacity you need, from half a ton up to 20 tons or more, depending on the model and design.

Control Systems

How you control the crane impacts safety and ease of use. Common options include:

- Pendant Control: Wired remote control hanging from the crane, simple and reliable

- Wireless Remote Control: Offers freedom to operate at a safe distance without cables

- Cabin Control: Operator sits in a cabin mounted on the crane for precise handling, usually for bigger cranes or complex operations

Mobility Options

Depending on your setup and how you plan to use the crane, different mobility features can be chosen:

- Fixed Rails: Most common, wheels run on fixed ground rails for precise, stable movement

- Wheels on Floor (Portable): Allows the crane to be moved freely without permanent tracks, good for flexible use

- Hydraulic Legs: Some cranes have adjustable legs that raise or lower the crane for easy repositioning or to fit uneven ground

Special Features

You can add features to make your crane work better in your environment:

- Weatherproofing: Protective coatings and sealed electrical parts for outdoor or harsh environments

- Anti-Sway Systems: Reduce load swinging for safer and more accurate handling

- Explosion-Proof Designs: Required in hazardous locations like chemical plants, with special electrical and mechanical safety measures

Materials and Finish

Material choice and paint coatings can improve durability and reduce maintenance:

- Use corrosion-resistant steel or stainless steel in harsh conditions

- Apply industrial-grade paint to protect from rust, UV, and chemicals

- Choose colors or markings that improve visibility and safety

Customizing your single girder gantry crane ensures it fits your operation perfectly, improves safety, and extends the crane's life — all while keeping costs in c

Advantages and Limitations of Single Girder Gantry Cranes

Single girder gantry cranes come with their own set of strengths and some trade-offs. Knowing both helps you decide if they're the right fit for your lifting needs.

Cost-Effectiveness Compared to Double Girder Cranes

One of the biggest benefits of single girder gantry cranes is their lower cost. Since they use only one main beam and lighter structural components, they require less material and simpler fabrication.

- Typically, purchase and installation costs are noticeably lower

- Reduced foundation or rail work compared to heavier cranes

- Ideal for budgets that don't allow for expensive heavy-duty cranes

Simpler Design and Easier Maintenance

With fewer parts and less complexity, these cranes are easier to maintain and service. This means less downtime and lower ongoing costs.

- Easy access to hoists and controls simplifies repairs

- Fewer mechanical parts reduce the chance of breakdowns

- Operators and maintenance teams can learn quickly and manage basic upkeep

Flexibility in Small to Medium Load Handling

Single girder cranes are perfect for light to medium loads, making them suitable across a wide range of industries and tasks. Their smaller size fits well in confined spaces.

- Can be customized for various spans and heights to fit your space

- Portable versions add flexibility in workshops and yards

- Ideal for lifting items like machine parts, pallets, and small equipment

Limitations in Heavier Loads and Longer Spans

Despite their advantages, single girder gantry cranes do have limitations. They are not suited for very heavy loads or wide spans where stability and strength become critical.

- Usually limited to loads up to about 20 tons, depending on design

- Less rigid structure means more deflection over longer spans

- Not recommended for heavy-duty, continuous, or high-frequency lifting tasks

Conclusion

Single girder gantry cranes offer a practical, cost-effective solution for many lifting needs, especially in small to medium-sized operations. Their range of models and customization options means you can find a crane tailored to your specific workspace, load requirements, and environment.

When choosing a crane, consider load capacity, span, duty cycle, environment, and control options carefully. Understanding the pros and cons helps ensure you get the best value and safest operation.

If you're unsure which crane fits your needs or want a custom solution, don't hesitate to reach out to experienced manufacturers or suppliers. They can guide you through the process and provide a crane that matches your exact requirements.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch