Monorail Overhead Cranes 1 to 20 Ton for Workshops & Warehouses

Monorail overhead cranes 1 ton to 20 ton for workshops and warehouses. Tailored overhead crane 1–20 tons, customizable, safe & efficient for your workflow.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Monorail Overhead Cranes for Sale – 1 to 20 Ton Solutions

Monorail overhead cranes are one of the most practical solutions for moving materials efficiently in workshops, warehouses, and small production facilities. Unlike a traditional double-girder bridge crane, a monorail crane runs along a single steel beam, giving it a compact footprint and making it ideal for spaces with limited headroom.

These cranes are designed to handle loads with precision and reduce the need for manual labor. They are particularly suitable for repetitive lifting tasks along a fixed path, such as moving parts from one workstation to another or transporting finished goods in a warehouse aisle.

Key Benefits of Monorail Overhead Cranes:

- Compact Design: Requires less space and can be installed in narrow aisles or low-ceiling workshops.

- Efficient Material Handling: Speeds up production and reduces downtime by allowing smooth, continuous transport of goods.

- Precise Load Movement: The hoist trolley moves along the monorail for accurate placement of materials, even in tight areas.

- Flexible Layouts: Can be installed on straight or curved paths depending on your workflow requirements.

Monorail cranes come in a wide range of capacities, typically from 1 ton to 20 tons, covering light to medium industrial applications. Whether you are lifting small machine parts or heavier components, there's a monorail crane that fits your workshop or warehouse setup.

Practical Tip: Before buying, consider your facility's dimensions, the weight of materials you handle most frequently, and the distance they need to travel. Choosing the right capacity will ensure safety, efficiency, and long-term reliability.

Types of Monorail Overhead Cranes

Monorail overhead cranes come in several designs to meet different workshop and warehouse requirements. Choosing the right type depends on your facility layout, lifting capacity needs, and headroom availability. Let's break down the main types.

Top-Running Monorail Cranes

Top-running monorail cranes are mounted on rails that sit above the crane's working area, usually on runway beams attached to the ceiling or supporting structures. These cranes are ideal for heavier loads and longer spans, making them suitable for industrial workshops with higher ceilings.

Why choose a top-running monorail crane:

- Can handle larger capacities, often approaching the upper range of 20 tons.

- Smooth operation over longer distances without interfering with floor space.

- Durable design for continuous, frequent lifting tasks in production lines.

Practical Tip: These cranes work best where headroom isn't an issue and you need reliable performance for medium to heavy loads.

Underhung / Underslung Monorail Cranes

Underhung monorail cranes are suspended directly from the ceiling or structural beams. The monorail itself acts as the track for the hoist trolley, which moves along it. This design is perfect for low-headroom areas or facilities where floor space must remain free.

Benefits of underhung monorail cranes:

- Space-efficient design for workshops with limited height.

- Cost-effective solution for handling 1–20 ton loads without requiring heavy runway beams.

- Easy installation and maintenance, especially in smaller facilities.

Practical Tip: Make sure the supporting structure can handle the crane's weight plus the maximum load for safety and long-term reliability.

Straight vs. Curved Monorail Systems

Monorail rails can be designed in straight or curved paths depending on workflow needs.

Straight Monorail Systems: Ideal for point-to-point transport of materials along a fixed line. Simple to install and maintain, they are commonly used in warehouses and assembly lines.

Curved Monorail Systems: Useful when materials need to navigate around obstacles or follow a more complex route. Curved tracks allow flexible layouts without multiple transfer points.

Practical Tip: When planning a curved monorail system, consider the minimum bending radius to ensure smooth trolley movement and reduce wear on the hoist.

Key Specifications & Features

When you're looking at a monorail overhead crane, knowing the key specifications is essential. These details help you choose a crane that fits your workshop or warehouse, ensures safe operation, and meets your material handling needs. From load capacity to hoist type, each feature plays a role in how the crane performs day to day.

Here are the main specifications to consider:

- Load Capacity: 1–20 tons: Monorail cranes are designed to lift anywhere from 1 ton up to 20 tons. Choosing the right capacity is critical for safety and efficiency. Overloading a crane can cause excessive wear, reduce its lifespan, and create dangerous working conditions.

- Span and Runway Length Customization: The span, which is the distance between support beams, and the runway length, which is the path the crane travels, can be customized to match your facility layout. Proper planning ensures smooth movement of the crane and prevents operational issues.

- Hoist Options: Electric Chain Hoist, Wire Rope Hoist: The hoist is the lifting mechanism. Electric chain hoists are compact and suitable for lighter loads, while wire rope hoists are more durable and ideal for heavier, more frequent lifts. The right choice depends on your specific material handling requirements.

- Speed: Single or Dual-Speed Lifting and Trolley Travel: Cranes may operate at a single speed or provide dual-speed options. Dual-speed allows precise positioning of loads, which is especially useful in assembly, packaging, or production processes requiring careful handling.

- Duty Classification and Industrial Standards (ISO, CE): Duty classification defines how often the crane can operate and under what load conditions. Ensuring your crane meets ISO or CE standards guarantees safety, reliability, and compliance with industrial regulations.

These specifications gives you a clear picture of how a monorail crane will perform in your facility. Properly matching the crane's capacity, span, hoist type, speed, and duty rating to your operational needs will save time, reduce maintenance costs, and improve overall efficiency.

Applications in Workshops & Warehouses

Monorail overhead cranes are widely used across a variety of industrial settings because of their efficiency and space-saving design. They are especially suited for facilities where materials need to be moved repeatedly along a defined path. By reducing manual lifting and transport, these cranes improve safety and workflow consistency.

Typical Applications:

- Material handling in factories, assembly lines, and storage facilities: Monorail cranes help move raw materials, components, and finished products efficiently from one station to another. In assembly lines, they can transport parts directly to the work area, minimizing downtime and simplifying operations. In storage areas, they enable safe lifting and stacking of heavy items.

- Automotive, metal fabrication, plastics, and light industrial workshops: Workshops in these industries often deal with medium-weight loads such as metal sheets, machine parts, or plastic molds. A monorail overhead crane provides precise control for placing these items, while freeing up floor space for other operations.

- Optimized for repetitive, point-to-point transport: Unlike bridge cranes that can cover a wide area, monorail cranes are perfect for fixed, repetitive movements, such as moving a machine part from a loading dock to a workstation. This makes them ideal for predictable workflows and high-frequency lifting tasks.

Buying Considerations

Choosing the right monorail overhead crane is more than just picking a model from a catalog. Several practical factors need to be considered to ensure safe, efficient, and long-lasting operation in your workshop or warehouse.

Before purchasing, think about the specific tasks the crane will perform, how often it will be used, and the layout of your facility. Matching the crane to your operational needs reduces downtime, prevents damage, and maximizes return on investment.

Key Factors to Consider:

- Available Capacity Range (1–20 ton) and Frequency of Operation: Select a crane with enough lifting capacity for your heaviest loads. Consider not only current needs but also potential future increases. Also, think about how often the crane will operate. Heavy-duty or frequent usage requires a crane rated for continuous operation.

- Space and Headroom Constraints: Measure your workshop or warehouse carefully. Underhung monorail cranes are great for low ceilings, while top-running cranes work better in high-ceiling areas. Make sure the crane's footprint fits without interfering with other equipment or workflows.

- Power Supply Requirements: Check that your facility can support the electrical requirements of the crane, including voltage, phase, and current. In some cases, upgrading your power supply may be necessary to safely run the crane.

- Safety Features: Look for built-in protections such as overload protection, limit switches, and an emergency stop. These features prevent accidents, protect your operators, and extend the crane's service life.

- Maintenance and Service Accessibility: A crane is only as good as its maintenance. Ensure there's easy access for inspections, lubrication, and minor repairs. Consider the availability of spare parts and the reliability of local service providers.

Installation & Maintenance Tips

Installing a monorail overhead crane correctly is critical for safe operation and long-term reliability. A poorly installed crane can lead to operational issues, safety hazards, and frequent maintenance needs.

Key Considerations for Installation and Maintenance:

- Preparing Runway Structures for Monorail Cranes: Ensure that all beams, supports, and columns can handle the crane's weight plus the maximum lifting load. The runway must be level and securely anchored to prevent sway or uneven motion during operation.

- Professional vs. In-House Installation: While some facilities may have skilled staff capable of installing a crane, professional installation is often recommended, especially for larger capacities. Certified installers ensure that the system meets all safety standards and operates smoothly from day one.

- Routine Inspections, Lubrication, and Troubleshooting: Regular inspections are essential to catch wear and tear early. Lubricate moving parts according to the manufacturer's guidelines, check electrical connections, and monitor hoist and trolley performance. Quick troubleshooting of minor issues can prevent costly downtime.

Practical Tip: Keep a log of inspections and maintenance. This not only improves safety but also helps with warranty compliance and long-term reliability.

Cost & Value Considerations

When evaluating a monorail overhead crane, it's important to look beyond the initial price tag. Costs can vary significantly depending on capacity, span, hoist type, and additional features.

Key Cost Factors:

- Pricing Based on Load Capacity, Span, and Hoist Type: Heavier load capacities and longer spans generally cost more. Hoist selection, whether electric chain or wire rope, also affects pricing. Understanding your exact requirements helps avoid paying for unnecessary features.

- Additional Costs: Installation, Customization, Accessories: Don't forget to factor in expenses for professional installation, optional customization for specific workflows, and accessories such as pendant controls, limit switches, or trolleys.

- Long-Term Value: Durability and Energy Efficiency: A well-built crane may have a higher upfront cost but can save money in the long run through reduced maintenance, energy efficiency, and longer operational life. Choosing a reliable supplier ensures both safety and consistent performance.

Practical Tip: Consider total cost of ownership, not just purchase price. A slightly higher investment upfront can prevent frequent repairs and downtime later.

Buying Options

When it comes to acquiring a monorail overhead crane, buyers have several options depending on their facility needs, budget, and timeline. Understanding the differences between available choices can help you make a more informed decision.

Key Considerations:

- Ready-Made vs. Customized Monorail Crane Systems: Ready-made cranes are quicker to deliver and usually cost less, making them suitable for standard workshops and warehouses. Customized systems, on the other hand, are tailored to your facility's layout, load requirements, and specific workflow needs. Customization ensures optimal performance but may take longer to manufacture.

- Local vs. International Suppliers: Local suppliers can provide faster delivery, easier communication, and on-site support. International manufacturers, especially reputable ones, may offer more advanced designs, wider capacity ranges, and competitive pricing. Assess the reliability, certification, and service capabilities of any supplier you consider.

- Warranty, After-Sales Support, and Spare Parts Availability: A strong warranty and accessible spare parts are crucial for long-term operation. Reliable after-sales support ensures that any issues are addressed promptly, minimizing downtime and maintaining safety standards.

Practical Tip: Check for CE or ISO certifications and ask for references from previous clients. This helps ensure the supplier's products and services meet industrial standards.

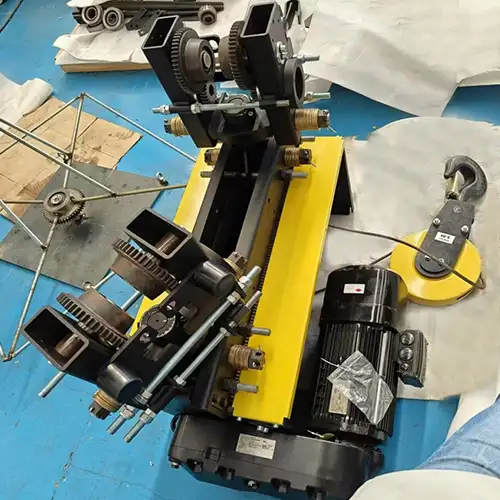

monorail overhead crane

curved monorail crane

Get Your Tailored Monorail Overhead Cranes

Monorail overhead cranes ranging from 1 to 20 tons provide an efficient, reliable solution for workshops and warehouses. They save space, improve workflow, and reduce manual labor, making them a practical choice for repetitive material handling tasks.

Choosing the right crane involves evaluating capacity, headroom, hoist type, speed, and safety features. Considering installation, maintenance, and supplier reliability ensures you get the best value and a crane that performs safely for years.

Practical Tip: A slightly higher initial investment in a quality crane pays off through durability, reduced downtime, and long-term efficiency.

For businesses looking to improve material handling and productivity, it's time to request a quote or consultation from trusted monorail crane specialists. This ensures you get the right system tailored to your facility and operational needs.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch