How to Calculate the Right Steel Mill Crane Capacity ?

A practical guide to help steel mill operators determine safe crane capacity with proper margins for various steel products. Get your steel mill crane!

Category: Featured

Your Trusted Steel Mill Overhead Crane Manufacturer & Supplier

How to Calculate the Right Lifting Capacity for Your Steel Mill Crane

A Practical Guide to Determining Safe Lifting Loads with Safety Margins for Various Steel Products

Introduction

Getting the lifting capacity right is not just a technical step—it's a daily concern in any steel mill that handles heavy products. Whether you're lifting billets, coils, or steel plates, your crane's capacity is directly tied to safety, productivity, and even maintenance costs.

Too often, buyers make the mistake of choosing a crane just based on the average weight they plan to lift. That's a trap. Loads are rarely uniform, and production conditions are never static.

Here's why it matters:

- Underestimating crane capacity means you risk overloading your equipment. That leads to faster wear, potential downtime, and in the worst-case scenario—accidents.

- Overestimating might sound safe, but it's not always practical. You'll likely spend more on the crane than you need to, increase energy use, and possibly complicate installation due to size and weight of the crane itself.

- Both mistakes cost time and money, and in steel mill operations, that adds up fast.

This guide will walk you through how to determine the correct lifting capacity for your steel mill crane. No vague talk—just clear steps, practical examples, and checklists you can actually use.

What you'll learn:

- How to assess the real weight of steel products (not just catalog specs).

- Why safety margins are necessary—and how much to add.

- What to consider when choosing between lifting one item or a full bundle.

- How future changes in production might affect your current choice.

- Common pitfalls and how to avoid them before placing your order.

Lifting Capacity of Steel Mill Overhead Cranes: The Basics

Every steel mill overhead crane has a limit. That limit—its lifting capacity—is what tells you how much weight it can safely handle during operation. But that number doesn't always tell the full story. Understanding the terms around it is just as important as the number itself.

What is Lifting Capacity?

In plain terms, lifting capacity is the maximum load a crane can lift under specific design conditions. It's determined by the crane's structural strength, hoisting equipment, and motor power. But keep in mind, this value only applies under normal working conditions—not extreme or unusual ones.

- This number is usually printed on the crane as the "Rated Load."

- It includes the weight of the load only, not the weight of the lifting attachment like a magnet, hook, or grab—those must be added separately during real calculations.

Static Load vs. Dynamic Load

Loads don't behave the same way once you start moving them.

- Static load is the weight your crane holds when it's not moving. Lifting something straight up and holding it still—this is where static load applies.

- Dynamic load comes into play the moment the crane starts lifting, lowering, accelerating, or stopping. That's when you feel the "shock" or "pull" that adds more force to the lifting components.

In steel mills where cranes handle heavy and sometimes unbalanced materials, dynamic loads can significantly increase the stress on your equipment.

Key Terms

These terms get mixed up a lot, so here's how to keep them straight:

- Rated Load – This is what the crane is designed and tested to lift safely under standard conditions. You'll often see this number displayed as "15t" or "20t" on the crane body.

- Working Load – This is the weight of the actual product being lifted, including the lifting tool if applicable.

- Maximum Load – The absolute top weight the crane components can handle before failure. You should never operate near this level—it's not a target, it's a danger zone.

Why Safety Margins Matter

You'll often hear suppliers say "Add 25% to your maximum load." That's not just sales talk—it's about giving your crane room to breathe.

- Safety margins account for unknowns: load imbalance, operator error, small shocks during movement, or wear and tear over time.

- The usual margin in steel mill settings is 20–30% over the maximum expected load.

- For hot materials or continuous-use duty cycles, margins may need to be even higher.

Think of it this way: If your heaviest load is 18 tons, you shouldn't be buying an 18-ton crane. You should be looking at something closer to 22 to 24 tons, depending on how often and how fast you'll be moving those loads.

Typical Capacities of Steel Mill Cranes

- Capacity Range: 5 to 500 tons (sometimes more)

- Purpose: Lifting molten metal in ladles during steelmaking

- Notes: Very high safety requirements; often redundant systems

Slab and Billet Handling Cranes

- Capacity Range: 30 to 150 tons

- Purpose: Moving hot or cold slabs and billets in rolling mills or yards

- Notes: May use clamps, magnets, or tongs; often semi-automated

- Capacity Range: 10 to 60 tons

- Purpose: Handling steel coils in cold/hot rolling and storage

- Notes: Frequently equipped with C-hooks or coil grabs

- Capacity Range: 40 to 150 tons

- Purpose: Transferring heavy ingots from casting areas

- Notes: Requires precise control and high-temperature resistance

Maintenance and Auxiliary Cranes

- Capacity Range: 5 to 20 tons

- Purpose: General plant maintenance, tooling, and smaller component handling

- Notes: May be single girder or light-duty bridge cranes

Scrap Handling Cranes (with magnets or grabs)

- Capacity Range: 10 to 75 tons

- Purpose: Loading scrap into furnaces

- Notes: Usually gantry or bridge cranes with magnet beams or orange-peel grabs

Main Capacities of Steel Mill Overhead Cranes

| Capacity | Common Uses | Application Areas | Notes |

|---|---|---|---|

| 10 Ton | Maintenance, spare parts, light-duty handling | Workshops, repair bays, auxiliary buildings | Typically single girder or light double girder cranes |

| 20 Ton | Billets, coils, pipes, bundled steel products | Steel warehouses, coil storage, fabrication shops | Hot-sale model for medium-duty operations |

| 30 Ton | Medium slabs, scrap bundles, forging components | Rolling mills, forming lines | Common choice for handling heavier steel with clamps or magnets |

| 50 Ton | Large billets, slabs, ingots | Slab yards, billet dispatch lines | Requires strong structures and higher motor capacity |

| 75 Ton | Coil stacking, hot slab transport, furnace loading | Coil yards, heating zones | Frequently paired with spreader beams or coil lifters |

| 100 Ton | Ladle lifting, casting line transfer | Melt shops, continuous casting zones | Usually with dual hoists, high-temperature resistance, safety class A6+ |

| 150 Ton+ | Molten steel ladles, extra-heavy slab or ingot handling | BOF shops, EAF, large casting platforms | Fully customized, often for critical lifts with backup systems |

Key Factors That Influence Crane Capacity Selection

Type of Steel Product Handled

Not all steel products are lifted the same way—and not all of them weigh the same either. The shape, size, weight, and surface condition of what you're lifting will directly affect what lifting capacity your crane needs. This is one of the first things we ask buyers when they request a quote.

Let's go through the typical steel products you'll find in a mill and how each affects crane selection.

Billets - Eletromangetic Overhead Crane for Billet Handling

Billets are usually square or rectangular bars of semi-finished steel.

- Common Sizes: 100mm x 100mm, 125mm x 125mm, 150mm x 150mm

- Length Range: 6 to 12 meters

- Unit Weight: 0.8 to 2.5 tons each, depending on size and length

- Bundle Lifts: Often lifted in bundles of 3 to 10 tons or more

Billets are compact, but they can be very hot and heavy, especially fresh from the continuous casting line. When bundled, the total weight can exceed 15 tons—don't underestimate the lift if using clamps or magnets.

Slabs

Slabs are wide and flat, which can make them trickier to handle.

- Common Sizes: Width 1.5–2.5 meters, Thickness 150–300mm, Length 4–8 meters

- Weight per Slab: Usually 8 to 25 tons

- Handling Note: Often lifted individually, not in bundles

Their large surface area means you'll need a well-balanced lifting system—like a spreader beam with clamps or magnets—and proper control to avoid tilting. Hot slabs can also distort lifting gear if not protected.

Coils are tightly wound rolls of hot-rolled or cold-rolled steel.

- Outer Diameter: 1.0 to 2.0 meters

- Width: 600 to 2,000mm

- Weight: 10 to 35 tons per coil is common

They're usually lifted either with a coil hook (through the inner eye) or C-hook. Your crane not only needs the capacity to lift a single heavy coil but also the precision to lower it into storage cradles or onto transport wagons without swinging.

Pipes and Tubes - Pipe Handling Steel Mill Cranes

Steel mills often move large bundles of pipes for structural or oil & gas industries.

- Bundle Weight: Can range from 2 tons to over 10 tons

- Length: Typically 6 to 12 meters

- Special Note: Thin-walled pipes may dent or bend if lifted incorrectly

For pipe handling, lifting beams with multiple slings or mechanical grabs help distribute the load evenly. Lifting pressure must be gentle but secure—especially with coated or thin-wall materials.

Ingots

Ingots are large cast blocks, often irregular in shape.

- Weight Range: 2 to 30+ tons

- Surface Condition: Hot and rough, often with scale or casting residue

These are rarely lifted in bundles, but their irregular shape means you may need custom grabs or magnet systems with adjustable lifting points. Friction and surface contact are key concerns.

Surface Condition: Hot, Cold, Oily, or Scaled?

This often-overlooked detail can change the entire lifting plan. Here's how:

- Hot Steel: Fresh from the furnace or rolling mill, the steel might be over 500°C. You'll need temperature-resistant lifting devices and crane motors rated for heat exposure.

- Cold Steel: Safer to handle, but if the surface is oily, slippery, or wet, magnets and clamps must be calibrated for added grip.

- Scaled or Rusty Surfaces: Steel with surface scale or corrosion may reduce magnetic lifting efficiency and damage mechanical clamps.

When in doubt, always tell your crane supplier the surface condition of your steel products—it affects both safety and equipment choice.

Lifting Method and Attachment Type

The way you lift a load is just as important as the load itself. In a steel mill, different products call for different lifting attachments. And those attachments—not just the product weight—play a direct role in determining the right crane capacity.

Let's go through the common lifting tools used in steel mills and how they affect your crane choice.

Common Lifting Equipment Types

Each tool below is designed with a purpose—and knowing which one you'll use helps define the actual load your crane must lift.

- Hooks:

Basic but reliable. Typically used for lifting with slings, chains, or coil hooks. Best suited for simple shapes like eye-through coils or bundles with lifting straps.

Important note: Hooks don't add much weight themselves, but slings or chains must be factored into your lift plan. - Clamps:

These grab the load with pressure—ideal for billets, slabs, and plates. They're available as mechanical, motorized, or hydraulic types.

Watch out: Clamp weight varies, and improper sizing or wear can cause slippage, especially on oily or scaled steel. - Magnets:

Very common in billet and scrap handling. Fast, clean, and efficient. Electromagnets are heavy—often between 1 to 5 tons each, depending on size and lifting force.

Key issue: You must include the magnet's dead weight in the total crane capacity calculation. - Grabs:

Often used for irregular-shaped steel (like scrap or ingots). These grab the load from the outside and require more room to maneuver.

Note: Grabs are not light. A full grab unit may weigh several tons even before touching the product. - Spreader Beams:

Used with hooks, magnets, or clamps to spread the lifting points and prevent bending or damage to wide loads.

Important detail: A spreader beam adds both weight and span to the crane system—especially critical in double-girder setups.

Lifting a Single Item vs. Bundled Loads

This is a practical difference buyers often overlook—and it's a costly mistake if missed.

- Single Item Lifting:

Straightforward. You know the item's weight, and you usually lift it with a single clamp, hook, or magnet.

Example: One 20-ton steel slab using a single clamp or magnet beam. Crane capacity = slab weight + lifting gear + safety margin. - Bundled Load Lifting:

Lifting multiple items at once increases the total weight and often the complexity of load balance.

Example: A billet bundle of 10 pieces at 2 tons each = 20 tons. Add a clamp beam at 2 tons, plus a 25% safety margin = crane must handle at least 27.5 tons.

When lifting bundles:

- Always clarify the maximum total weight of a bundle, not just the unit weight.

- Consider how the lifting device grips the entire bundle—uniform pressure is essential to avoid slippage.

- Movement dynamics (like swing, tilt, or misalignment) become more pronounced with bundled loads.

Frequency of Operation and Duty Class

How often you use your overhead crane—and how hard it works each time—plays a big role in selecting the right lifting capacity and mechanical structure. This isn't just about how much the crane can lift at once; it's also about how long it will last under regular operation.

Steel mills are high-demand environments. Cranes don't just lift heavy—they lift often, and sometimes continuously. That's where duty class matters.

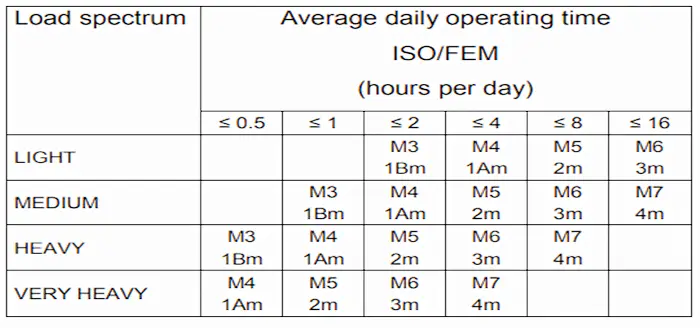

Duty Classification (FEM/ISO Standards)

Cranes are classified by international standards like FEM (European Federation of Materials Handling) and ISO, which group cranes based on how frequently they operate and how much load they typically handle. Here's the short version:

- FEM Classes: 1Bm, 1Am, 2m, 3m, 4m

Higher number = heavier use and longer life expectancy

Commonly used in European systems - ISO Classes: M1 to M8

M1 = light use (like a garage hoist), M8 = extremely heavy use (like a casting crane in a steel mill)

For example:

- A 5-ton workshop crane used twice a day might be ISO M3.

- A 20-ton billet crane running 24/7 could be ISO M7 or M8.

You can think of duty class as the crane's work stamina. Just because a crane is rated for 20 tons doesn't mean it can do that all day long without wear.

How Usage Frequency Affects Capacity Selection

Now here's the part that buyers sometimes overlook:

- If you're lifting at or near full capacity all the time, you need a higher duty class crane.

- If you're lifting light loads most of the time, but occasionally go heavy, a medium duty crane may do just fine.

- If you're doing repetitive lifting in a production cycle (like in billet or coil yards), you'll need a high-duty motor and brake system, not just strong girders.

Let's break it down with some examples:

- Light Duty (ISO M3 / FEM 1Bm):

Occasional lifts, low total running time per day

Example: 5-ton crane in a maintenance bay or tool room - Medium Duty (ISO M5 / FEM 2m):

Frequent lifts with varied loads, moderate daily use

Example: 10-ton coil crane in a logistics zone used 8–10 hours/day - Heavy Duty (ISO M7–M8 / FEM 3m–4m):

High-frequency lifts, close to rated capacity, continuous use

Example: 30-ton billet magnet crane in the hot rolling mill operating 24/7

Don't Over- or Under-Spec

Choosing the wrong duty class can lead to two problems:

- Under-specifying: You'll save upfront but spend more on breakdowns, overheating motors, and premature gear wear.

- Over-specifying: You'll pay more than you need—for strength and speed you won't actually use.

Environmental and Structural Constraints

It's not just about what you lift—but where you lift it. Steel mills are harsh places, and the crane's environment often has just as much impact as the weight it carries. If you ignore conditions like heat, dust, or tight spaces, you'll end up with a crane that's hard to operate—or worse, one that breaks down quickly.

Environmental Conditions That Affect Crane Design

Some cranes in steel mills operate in clean areas, like packaging zones or finished product warehouses. Others work over furnaces, in casting bays, or inside scrap pits. Each of these locations has different demands.

High Temperatures:

Especially near continuous casting lines or reheating furnaces. Motors, electrical cabinets, and cables must be heat-protected or rated for higher ambient temperatures (sometimes up to 70°C).

Tip: Install sunshades, insulation, or forced ventilation when ambient heat is unavoidable.

Dust and Particulates: Fine metallic dust, scale, and carbon build-up can clog motors, bearings, and control systems.

- Use sealed motors and enclosed gearboxes.

- Install air filters in control cabinets.

- Schedule regular clean-outs of crane trolleys.

Moisture, Corrosion, and Humidity: Outdoor cranes, or cranes near pickling lines, often face rust issues.

- Opt for anti-corrosive paint, galvanized components, or stainless covers where needed.

- Electrical components should have IP55 or higher protection.

Explosive or Flammable Atmospheres: Certain zones may require explosion-proof cranes, especially near coal handling areas or oxygen-rich steelmaking setups.

- These cranes need spark-resistant components, flameproof enclosures, and non-sparking brakes.

- A certified EX-proof hoist and control system is non-negotiable in such zones.

Structural Factors You Can't Ignore

Crane capacity is also shaped by the physical limits of your building. Whether it's an old mill or a new plant, structure affects everything from girder design to hoist choice. Click to learn more on Assessing Your Facility's Space: How Headroom Affects Crane Selection.

Low Headroom: In older facilities or workshops with limited roof space, there's often not enough clearance for standard hoist trolleys.

- Use low-headroom or compact hoist designs.

- Underrunning cranes might work better in small bays.

Crane Span: Long-span cranes (20+ meters) must be designed to minimize beam deflection and torsional stress—especially for heavy lifting.

- Double girder cranes are usually better at handling long spans and heavier loads.

Runway Constraints and Support Beams: Sometimes your runway columns or support beams are too weak or irregularly spaced.

- Run a structural check to confirm load-bearing capacity.

- Modular crane kits or custom brackets may help in tricky layouts.

Integration Into Existing Facilities: If you're upgrading or replacing a crane in a running plant, you'll need:

- A tailored design that fits your current runway system

- Compatible power supply (voltage, frequency)

- Smooth installation with minimal downtime

Practical advice: Always have an environment and building layout checklist ready when talking to a crane supplier. It'll save time, avoid mismatches, and lead to a better long-term fit.

Step-by-Step Guide to Calculating Crane Capacity

Getting your crane's lifting capacity right isn't just a matter of plugging in a number. It's a mix of hard data, safety thinking, and a clear view of your steel mill's actual working conditions. Let's go through it step by step, in a way that helps you explain the logic to your procurement team or crane supplier.

Step 1: Identify the Heaviest Load

The first thing you need to know: What's the absolute heaviest thing this crane will ever lift?

And don't just go by what you usually lift. Go by the worst-case scenario—the biggest slab, the heaviest coil, or that extra-large bundle of billets.

Include everything: product weight, packaging, lifting attachments

Example:

- A steel coil weighs 18 tons

- It's strapped and loaded onto a pallet (500 kg)

- A C-hook weighs another 1.5 tons

- Total: 20 tons

Check for variations:

- Will some products arrive in bundled form?

- Are there oversized or irregular shapes that shift center of gravity?

- Do any items require special grips or fixtures?

Use real numbers, not guesses:

- Weigh actual products if possible

- Ask your logistics team for shipping weights

- Review supplier packing lists for incoming raw materials

One mistake many buyers make? They forget to add the weight of the lifting device itself. A magnet beam or coil grab can weigh 1–5 tons by itself—don't leave it out.

Step 2: Add a Safety Margin

Once you know the heaviest realistic load, you need to pad the number to cover unexpected conditions, operator variations, or material shifts during the lift.

The general rule is simple:

Add 20% to 30% on top of your maximum load.

- For basic mill logistics or warehouse use:

20% is usually enough - For critical processes, hot materials, or where load swinging is possible:

Go up to 25–30% - If your local safety code (e.g. in Europe or North America) mandates a different margin:

Follow the stricter rule

Example Calculation

- Heaviest load: 20 tons

- Safety margin: 25%

- Total required lifting capacity:

20 tons × 1.25 = 25 tons

→ Choose a 25-ton crane, not a 20-ton one

This safety margin isn't just about weight. It also compensates for:

- Unexpected dynamic forces (from swinging or sudden braking)

- Operator error

- Gradual wear in mechanical parts over time

And yes, your crane will almost never lift that full 25 tons—but it needs to be built to do it safely in the rare case that it does.

Step 3: Consider Future Needs

Don't size your crane just for today—think ahead a few years. Steel mill operations evolve. New product lines get added. Output capacity increases. Shapes and weights change. Your crane should be able to adapt without becoming a bottleneck.

Ask These Questions:

- Will we handle larger billets, coils, or custom shapes in the future?

- Are there expansion plans for new production lines?

- Will automation or remote operations increase crane usage?

- Could outsourced operations be brought in-house (requiring heavier lifts)?

When to Oversize:

It's often smart to add 10–15% extra capacity beyond your current safety-margined total, especially in fast-growing operations. Why?

- It avoids replacing the entire crane system later.

- It adds flexibility to lift heavier or multiple products in one go.

- It's easier to handle unforeseen orders or contract changes.

Example

- Today's max load with margin: 25 tons

- Planning for potential heavier coil production (say 28–30 tons)?

→ Consider a 32-ton crane to avoid future replacement costs.

A bit of overcapacity now can save hundreds of hours of downtime later. But don't overdo it—oversizing too much can increase cost, weight, and maintenance without benefit.

Step 4: Match with Crane Type

The lifting capacity you calculated is only part of the story. Now match it with the right type of overhead crane system that can safely and efficiently handle your needs.

Choose the Right Crane Configuration:

Single Girder Bridge Crane

- Best for light to moderate loads (under 20 tons), shorter spans

- Lower cost, quicker install

- Compact design for low headroom workshops

Double Girder Bridge Crane

- Ideal for heavier loads (20 tons and up), longer spans

- Allows more lifting height (hoist rides between girders)

- More durable for high-frequency use

Gantry Crane

- Useful where no building structure exists

- Common in outdoor yards or near furnaces

- Flexible in layout, can be rail-mounted or rubber-tyred

Semi-Gantry or Wall-Mounted Systems

- When one side needs to be fixed to a building structure

- Saves floor space but offers partial span coverage

Confirm the Supporting Systems Match:

- Motors should be rated for the duty cycle (FEM/ISO class) and max torque needs

- Hoist must align with load weight, frequency of use, and control precision

- Controls should support overload protection, limit switches, and smooth acceleration/deceleration

- Structure must be rigid enough to minimize deflection under full load

A mismatched crane system—like using a single girder when a double girder is needed—leads to stress damage, downtime, or safety violations. Always balance capacity, design, and usage class.

Sample Calculations for Common Steel Products

Calculating the right crane capacity starts with knowing the exact weights and sizes of the products you handle. Different steel products have different shapes, densities, and handling methods — so their lifting calculations vary.

Billets

Billets are long, semi-finished steel bars, often bundled together.

- Typical weight per billet: Depends on length and cross-section. For example, a 150 mm × 150 mm billet that's 6 meters long weighs about 1050 kg.

(Density of steel ≈ 7,850 kg/m³) - Bundle size: Usually stacked in bundles of 10 to 20 pieces.

If one billet weighs 1 ton and you lift 15 in a bundle, that's 15 tons. - Lifting method: Usually by clamps or magnets. The clamp or magnet weight should be included in total lifting weight.

Sample calculation:

| Parameter | Value | Unit |

|---|---|---|

| Billet cross-section | 150 × 150 | mm |

| Billet length | 6 | m |

| Steel density | 7,850 | kg/m³ |

| Number of billets | 15 | pieces |

| Clamp weight | 1,500 | kg |

| Total weight | (calc below) | kg or tons |

Calculation:

- Volume of one billet = 0.15 m × 0.15 m × 6 m = 0.135 m³

- Weight of one billet = 0.135 m³ × 7,850 kg/m³ = 1,059.75 kg (≈1.06 tons)

- Weight of 15 billets = 1.06 × 15 = 15.9 tons

- Add clamp weight (1.5 tons) = 15.9 + 1.5 = 17.4 tons

Recommended crane capacity with 25% safety margin: 17.4 × 1.25 = 21.75 tons → Choose a 22-ton or 25-ton crane.

Coils

Coils vary widely but have a simple cylindrical shape.

- Dimensions: Diameter and width are the key.

- Material thickness: Typically 0.5 mm to 5 mm for sheet coils.

- Weight estimation: Weight (kg) = (Outer diameter² − Inner diameter²) × Width × Density × 0.02466

The constant 0.02466 accounts for unit conversion and π.

Sample calculation:

| Parameter | Value | Unit |

|---|---|---|

| Outer diameter | 1,200 | mm |

| Inner diameter | 500 | mm |

| Width | 500 | mm |

| Steel density | 7,850 | kg/m³ |

Calculation:

- Weight = (1,200² − 500²) × 500 × 7.85 × 0.000001 × 0.02466

- = (1,440,000 − 250,000) × 500 × 7.85 × 0.000001 × 0.02466

- = 1,190,000 × 500 × 7.85 × 0.000001 × 0.02466

- Calculate stepwise to get approx. 7200 kg or 7.2 tons

Add lifting attachments weight if using coil hooks or magnets.

Slabs and Plates

- Surface area: Length × Width

- Thickness: Usually between 0.15 m to 0.30 m

- Weight: Volume × Density

Sample calculation:

| Parameter | Value | Unit |

|---|---|---|

| Length | 6 | m |

| Width | 2 | m |

| Thickness | 0.2 | m |

| Density | 7,850 | kg/m³ |

- Volume = 6 × 2 × 0.2 = 2.4 m³

- Weight = 2.4 × 7,850 = 18,840 kg (18.8 tons)

If lifting multiple slabs, multiply by the number in the bundle.

Pipes

Weight depends on diameter, wall thickness, and length.

- Weight per meter (kg/m) formula: Weight/m = π × ( (D_outer/2)² − (D_inner/2)² ) × Density

- Bundle weight: Weight/m × length × quantity

Sample calculation:

| Parameter | Value | Unit |

|---|---|---|

| Outer diameter | 300 | mm |

| Wall thickness | 10 | mm |

| Length | 6 | m |

| Quantity | 20 | pieces |

| Density | 7,850 | kg/m³ |

- Inner diameter = 300 − 2 × 10 = 280 mm = 0.28 m

- Outer diameter = 300 mm = 0.30 m

- Cross-sectional area = π × ( (0.30/2)² − (0.28/2)² )

= 3.1416 × (0.15² − 0.14²)

= 3.1416 × (0.0225 − 0.0196)

= 3.1416 × 0.0029 = 0.0091 m² - Weight per meter = 0.0091 × 7,850 = 71.4 kg/m

- Weight of one pipe = 71.4 × 6 = 428.4 kg

- Total bundle weight = 428.4 × 20 = 8,568 kg (8.57 tons)

Input Table Template for Your Calculations

| Product Type | Unit Weight (kg) | Quantity per Lift | Lifting Device Weight (kg) | Total Load (kg) | Safety Margin (%) | Required Capacity (kg) |

|---|---|---|---|---|---|---|

How to use:

- Fill in your product's unit weight and how many you lift at once.

- Add the weight of clamps, magnets, or other devices.

- Multiply by safety margin to get recommended crane capacity.

Special Cases and Customization Tips

Steel mill lifting isn't always straightforward. Sometimes, your operation has special challenges that need extra attention. Handling hot materials, uneven loads, or varied product types means your crane must be designed or customized carefully. Here's what to keep in mind.

Handling Hot or Semi-Molten Materials

When lifting steel at high temperatures — like red-hot billets or slabs fresh from the furnace — standard crane components can quickly wear out or fail.

- Heat-resistant materials: Use specially coated or heat-proof wires, hooks, and crane parts to withstand temperatures often exceeding 600°C (1,100°F).

- Protective covers: Shields for motors, control panels, and wiring protect against radiant heat and sparks.

- Special hoists: Electromagnetic or clamp hoists designed for high-temp operation reduce damage risk.

- Thermal expansion: Design allowance for crane structure expansion/contraction due to heat fluctuations prevents misalignment or structural damage.

Managing Uneven, Shifting, or Unbalanced Loads

Steel products are sometimes bundled unevenly or shift during lifting — creating unbalanced loads that stress the crane and risk accidents.

- Load distribution: Use spreader beams or multi-point lifting devices to balance weight evenly across the crane hook.

- Dynamic load monitoring: Some cranes have sensors or load cells that detect uneven loads and warn the operator.

- Stronger safety factors: Increase safety margins beyond standard 25–30% when unbalanced or shifting loads are common.

- Operator training: Ensure crane operators understand the risk of load shifts and proper rigging techniques.

Designing Cranes for Mixed-Use Steel Processing Environments

In many mills, the crane must handle a variety of steel products — from heavy slabs to delicate coils — and different lifting methods.

- Modular lifting attachments: Equip the crane with quick-change clamps, hooks, magnets, or grabs to adapt to different products easily.

- Adjustable lifting height and speed: Variable hoist speeds and height limits help protect delicate products while moving heavy loads efficiently.

- Robust control systems: Programmable controllers or automation allow switching between lifting modes, improving safety and precision.

- Structural design: Crane structures must be strong yet flexible enough to handle diverse load patterns and weights without excessive wear.

Common Mistakes to Avoid

Selecting the right lifting capacity for your steel mill crane is critical—but it's easy to make mistakes that can lead to serious safety issues, equipment damage, or costly downtime. Many of these mistakes come from overlooking important details in load calculations or operational realities. Let's dive into the most common pitfalls and how to avoid them with practical steps.

Forgetting to Include the Weight of the Lifting Attachment in Total Load Calculations

One of the most frequent errors is to calculate the crane capacity based only on the steel product's weight, ignoring the lifting attachments like clamps, hooks, magnets, spreader beams, or grabs. These attachments can add significant extra weight, sometimes even 5-10% or more of the load weight.

- Why it's a big deal: If you ignore the attachment's weight, you are underestimating the total load on the crane. This can cause overload conditions that strain the crane's hoist, trolley, bridge, and structural components. Over time, this leads to premature wear, mechanical failures, or even catastrophic accidents.

- How to avoid it: Always get the exact weight of the lifting device from your equipment supplier or manufacturer specifications. Add this figure to the weight of the steel product before calculating the total load. For example, if you are lifting a 10-ton bundle of slabs with a 1.5-ton clamp, your base load becomes 11.5 tons before safety margins.

- Extra tip: Consider any additional rigging or slings used during lifting. Their weight, though often small, should be accounted for especially if you are near the crane's capacity limit.

Failing to Differentiate Between Single Lifts and Bundled Lifts

In steel mills, many products are handled in bundles rather than individually. The weight, dimensions, and load dynamics of bundles differ significantly from single items.

- Common mistake: Assuming that the crane only needs to lift single pieces can lead to serious undercapacity if bundled lifts are part of daily operations.

- Why it matters: Bundled loads often multiply the weight several times. For example, one slab may weigh 2 tons, but a bundle of five slabs can weigh over 10 tons. The crane must be designed to handle the heaviest bundle, not just a single slab.

- What you should do: Survey your actual lifting operations. Confirm if you are lifting single items, bundles, or both. Calculate the maximum possible bundle weight including any attachments and rigging. Always design crane capacity based on the heaviest load expected, not the average.

Additional considerations:

- Bundled loads may have uneven weight distribution or shift during lifting. This requires additional safety margins and sometimes specialized lifting attachments like spreader beams.

- Consider how the size of bundles affects crane hook clearance and safe operating radius.

Overlooking How Wear and Maintenance Affect Lifting System Capacity Over Time

Cranes operate in harsh environments and heavy-duty conditions. Over time, wear and tear on hoist ropes, hooks, brakes, motors, and structural parts reduce the crane's actual lifting performance and safety margin.

Why it's critical: Relying on the original rated capacity without considering equipment aging can lead to dangerous overloads and failures. For example, worn ropes have lower tensile strength, and degraded brakes might fail to hold loads securely.

Steps to mitigate this risk:

- Implement a strict preventive maintenance program that includes regular inspection of critical components like wire ropes, hooks, brakes, limit switches, and motors.

- Replace worn or damaged parts promptly; don't wait for complete failure.

- Use condition monitoring where possible—load sensors, rope inspection devices, and brake performance tests.

- Consider oversizing the crane capacity by 10-15% to allow for the natural loss of strength over time and unforeseen load variations.

- Keep detailed maintenance logs to track the crane's condition and predict when parts will need replacement.

Operator awareness: Train crane operators and maintenance teams to recognize signs of wear and report any unusual noises, vibrations, or handling difficulties immediately.

Final Checklist Before You Buy

Buying a steel mill crane is a big investment. Getting it right upfront saves headaches, delays, and extra costs later on. Before you sign the deal, make sure you've covered these essential points to ensure your new crane meets your operational needs safely and efficiently.

Confirm Your Maximum Lifting Load Including Safety Margin

Don't just take the weight of your heaviest steel product at face value. Remember to add the full weight of any lifting attachments such as clamps, magnets, hooks, or spreader beams.

- Calculate the total maximum load by adding these together.

- Apply a safety margin, typically 20–30%, depending on your local safety standards and operating risks.

- Double-check that this final number matches or is below the crane's rated lifting capacity.

This is the baseline figure that the crane must safely handle every day.

Validate the Compatibility of Lifting Attachments With Your Steel Products

Not all attachments work equally well with every type of steel product.

- Confirm that your chosen clamps, magnets, grabs, or hooks are designed for the specific steel items you'll handle—whether slabs, coils, billets, pipes, or ingots.

- Check the size, shape, and surface condition (hot, oily, scaled) of your steel products to ensure the attachment can grip securely and safely.

- Ask your crane supplier for recommendations or custom-designed lifting devices if your products are unusual or difficult to handle.

Proper attachment compatibility helps prevent load slips, accidents, and damage to your materials or crane.

Check That Crane Capacity Matches the Required Duty Class

Cranes are rated not just by lifting capacity but also by how often and how intensely they will be used — the duty class.

- Refer to FEM or ISO duty classifications relevant to your country or industry.

- Make sure your crane's duty class matches your expected operating cycles, frequency of lifts, and load types.

- If you plan heavy use, high frequency, or shock loading, choose a crane with a higher duty rating to avoid premature wear and breakdowns.

Using a crane under-rated for your duty class leads to maintenance problems and safety risks.

Consider Long-Term Flexibility for Production Changes

Steel mill operations evolve. New products, changes in bundle sizes, or increased output might require different crane performance in the future.

- Think about whether a slightly higher capacity crane would make sense to cover future growth or changes.

- Consider cranes with modular designs or adjustable features like variable speed hoists, which can adapt to different load sizes or speeds.

- Talk with your supplier about upgrade paths or options for adding features later.

Investing in flexibility now prevents costly crane replacements or modifications down the road.

Review Available Customization Options From Your Crane Supplier

Off-the-shelf cranes often need some customization to fit your exact operational conditions.

- Ask about special materials or coatings if your crane will operate in extreme temperatures, dusty or corrosive environments, or explosive atmospheres.

- Check for available options like remote controls, automation, or safety monitoring systems.

- Confirm how the crane will integrate into your existing facility layout, including runway beams, headroom limits, and power supply compatibility.

- Don't hesitate to request case studies or references for similar crane installations.

A good supplier will work with you to tailor the crane's design for your unique needs and ensure smooth installation and long-term operation.

Taking these checklist items seriously ensures your steel mill crane will be safe, reliable, and a good fit for your current and future needs. If you want, I can help you build a detailed, easy-to-use pre-purchase checklist customized for your specific steel mill operations.

Conclusion

Choosing the right lifting capacity for your steel mill crane is crucial. It's about much more than just numbers on paper — it directly impacts safety, efficiency, and costs over the life of the crane.

- Why it matters: Getting your capacity planning right means your crane will safely handle the heaviest loads, work reliably day after day, and be ready if your production changes.

- What can go wrong: Underestimating capacity risks breakdowns and safety issues. Overestimating means spending more than needed on bigger equipment and higher energy use.

- Who to turn to: Because every steel mill is different, it's smart to bring in crane experts or your engineering team. They can look at your specific needs and help pick the best solution.

- Extra help: Many suppliers offer free crane capacity assessments or quotes. Using these services is a smart way to double-check your plans and avoid costly mistakes.

- Bottom line: Take the time now to plan carefully. A well-chosen crane keeps your mill running smoothly, safely, and ready for the future.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch