Overhead Crane Types: All Types of Overhead Cranes for Sale in China

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Crane Types: All Types of Overhead Cranes for Sale in China

1 ton - 320 ton cost-effective Chinese types of overhead cranes

Before choosing the specific overhead crane for your application, it is crucial to understand the various types of overhead cranes that are available as well as the features and benefits of each type. You can choose the crane types, working duty class, space requirements, and financial constraints that will work best for you once you have the necessary information.

In this blog, we'll go over the benefits and applications of the five main types of overhead cranes, as well as the available configurations.

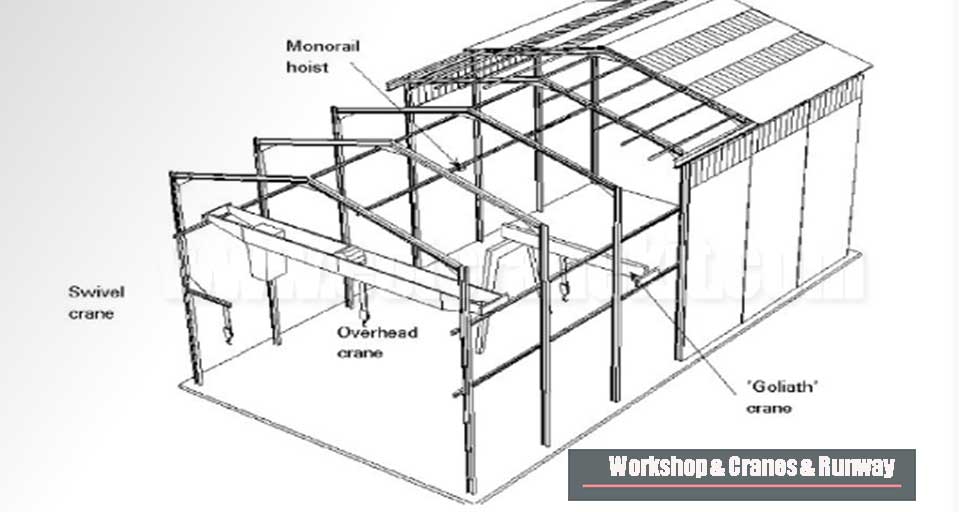

5 Main Types of Electric Overhead Cranes

Here are the 5 basic types of overhead cranes :

Light Lifting Equipment:Light lifting equipment - The types of lifting equipment, mainly consisted of Electric hoist, chain hoist, electric chain hoist, miniature hoist, etc.. The light hoisting equipment is designed with the features of light and compact structure, light weight, small size, and strong versatility of parts, etc.

- Manuel chain hoist

- Electric chain hoist

- Electric wire rope hoist

- Monorail hoist and crane systems

- Portable cranes

- Bridge Cranes

Overhead Bridge Crane

Overhead bridge crane - The bridge crane is the most common used material handling equipment. It is erected on the track mounted on the crane runways supported or partially supported by the inner building structure. They are widely used in workshops and warehouses, for loading and unloading works and heavy loads or object handling works indoors and outdoors. They are also called overhead travelling bridge crane, overhead crane, and eot crane, and overhead gantry crane, etc.

- - Single Girder and Double Girder Bridge Cranes

- - Top Running and Underhung Bridge Cranes

Gantry Cranes

Gantry crane - The gantry cranes are similar with bridge crane, with self supporting legs running on the rails, embedded on the ground, instead of on the runway beams supported by building structure. It is generally called gantry crane or Goliath crane in the factory.

- - Single girder gantry crane

- - Double girder gantry crane

Rotating jib crane

Jib type crane - The types of cranes covers portal cranes, fixed slewing cranes, shore-to-shore container bridge cranes, etc.

- Wall travelling crane

- Wall mounted crane

- Floor mounted pillar jib crane

- Workstation Cranes

Workstation Crane

A workstation crane is a type of overhead crane that is designed for light-duty applications and is typically used in a smaller work area, such as a manufacturing cell or assembly station. These cranes are often used to move materials or products from one workstation to another, and they are typically operated manually.

There are several types of workstation cranes, including:

- Freestanding workstation cranes

- Ceiling-mounted workstation cranes

- Kbk crane

Your Trusted Overhead Crane Manufacturer & Supplier

Light lifting equipment: Types of Manual Hoist and Electric Hoists

Manual and Electric Chain Hoist and Electric Wire Rope hoists

Manual chain hoist

It is also called chain block, manual hoist, hand hoist, or hand operated hoist, etc.

It is a manual lifting machine that is easy to use and easy to carry. It is suitable for short-distance lifting and transportation of small equipment and goods. The lifting capacity of manual chain hoist generally does not exceed 100 ton. The shell of the chain hoist is made of high-quality alloy steel, which is strong and wear-resistant, and has high safety performance.

Famous brands of chain hoists -Korea (DK) black bear, Japan (SPEED) Erye, Japanese (KITO) Ghost Head,Japan (TOYO) Toyo,Japan (EAGLE) Eagle,etc.

Manual chain hoists, also known as hand chain hoists, are a type of material handling equipment that are operated manually by pulling a chain to lift and move heavy loads. There are several types of manual chain hoists, including:

- Hook Mounted Manual Chain Hoist: This type of manual chain hoist is mounted on a hook and can be attached to a trolley or other lifting device.

- Trolley Mounted Manual Chain Hoist: This type of manual chain hoist is mounted to a trolley that moves along a beam or track, allowing the hoist to move horizontally as well as vertically.

- Low Headroom Manual Chain Hoist: This type of manual chain hoist is designed for use in areas with limited headroom, where a traditional hoist would not fit.

- Geared Manual Chain Hoist: This type of manual chain hoist is designed for use in applications where precise load control is required. It features a gear system that allows for slow and controlled lifting and lowering of loads.

- Lever Manual Chain Hoist: This type of manual chain hoist is operated by pulling a lever to lift and move loads. It is typically used in applications where the operator needs to maintain control over the load at all times.

- Explosion-proof manual chain hoists are designed for use in hazardous environments where there is a risk of explosion due to the presence of flammable gases or vapors. These hoists are constructed with special materials and features that prevent sparks from being generated during operation, reducing the risk of ignition.

- Stainless steel chain hoists are designed for use in applications where corrosion resistance is important, such as in food processing or marine environments. These hoists are constructed with stainless steel components that are resistant to rust and other forms of corrosion.

Hand chain hoist

Hand push chain hoist

Lever chain hoists

Low headroom chain hoist

Explosion proof

Stainless steel chain hoist

Manual chain hoists are typically used in applications where electricity is not available or where a power source is not practical. They offer several advantages, including:

- Good performance and easy maintenance. They are cost-effective and require minimal maintenance.

- They are easy to operate and require minimal training.

- In line with national standards, safe and reliable, durable.

- Strong toughness, small size, light weight, easy to carry

- Small hand pulling force and high mechanical strength

- Advanced structure and beautiful appearance

- Lifting goods in areas without power supply

- They can be used in a variety of settings, including construction sites, warehouses, and assembly lines.

- However, manual chain hoists also have some limitations, including:

- They have lower lifting capacities than electric or hydraulic hoists.

- They may require more physical effort to operate than other types of hoists.

- They may not be suitable for applications where high speeds or long travel distances are required.

Electric chain hoists

An electric chain hoist is a type of material handling equipment that is used to lift and move heavy loads. It consists of a motorized chain that runs through a hoist unit, which is suspended from a trolley that moves along a beam or track. Electric chain hoists are commonly used in manufacturing and industrial settings.

There are several types of electric chain hoists, including:

- Hook Mounted Electric Chain Hoist: This type of electric chain hoist is mounted on a hook and can be attached to a trolley or other lifting device.

- Trolley Mounted Electric Chain Hoist: This type of electric chain hoist is mounted to a trolley that moves along a beam or track, allowing the hoist to move horizontally as well as vertically.

- Low Headroom Electric Chain Hoist: This type of electric chain hoist is designed for use in areas with limited headroom, where a traditional hoist would not fit.

- Explosion-proof electric chain hoists are designed for use in hazardous environments where there is a risk of explosion due to the presence of flammable gases or vapors. These hoists are constructed with special materials and features that prevent sparks from being generated during operation, reducing the risk of ignition.

- European-style electric chain hoists, also known as low headroom hoists, are designed for use in areas with limited headroom. These hoists feature a compact design that allows them to be installed in areas with low ceilings or other obstructions. They are typically used in manufacturing and industrial settings where space is at a premium.

Electric trolley electric chain hoist

Manual trolley electric chain hoist

Hook mounted electric chain hoist

Low headroom electric chain hoist

Explosion proof electric chain hoist

European style electric chain hoist

Features of electric chain hoists include:

- They are available in a range of lifting capacities, from a few hundred pounds to several tons.

- They are easy to operate and require minimal training.

- They can be used in a variety of applications, including assembly lines, warehouses, and construction sites.

- They can be customized to fit specific applications.

Advantages of electric chain hoists include:

- They are cost-effective and require less maintenance than other types of hoists.

- They are easy to install and can be used in a variety of settings.

- They are relatively quiet and produce less vibration than other types of hoists.

- Limitations of electric chain hoists include:

- They have lower lifting capacities than other types of hoists, such as wire rope hoists.

- They may not be suitable for applications where high speeds or long travel distances are required.

- They may require additional support structures to be installed in the building

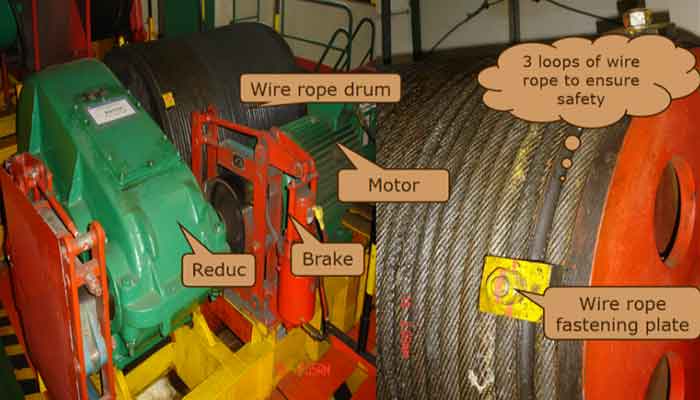

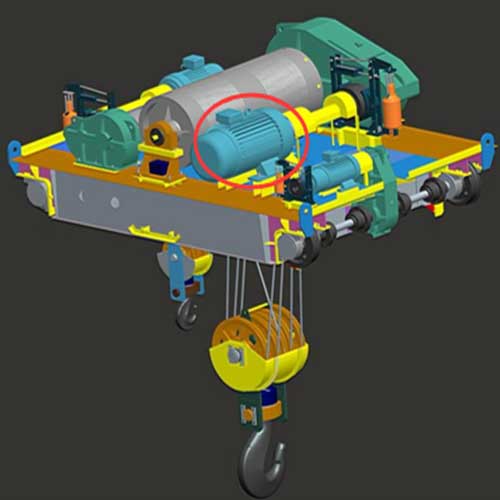

Electric wire rope hoists

Electric wire rope hoists are a type of material handling equipment that are used to lift and move heavy loads. They consist of a motorized drum that rotates a steel cable or wire rope, which is attached to a hoist unit that moves up and down to lift and lower the load. Electric wire rope hoists are commonly used in manufacturing and industrial settings.

Main series of electric wire rope hoists

The different types of electric wire rope hoists:

- CD1—ordinary single-speed electric hoist: This type of hoist has a single lifting speed and is suitable for applications where precise load control is not required. It is commonly used in manufacturing and industrial settings.

- MD1—ordinary two-speed electric hoist: This type of hoist has two lifting speeds and is suitable for applications where precise load control is required. It is commonly used in manufacturing and industrial settings.

- YH—metallurgical electric hoist: This type of hoist is designed for use in metallurgical applications, such as steel mills or foundries. It is constructed with specialized materials that can withstand high temperatures and harsh environments.

- BCD—Explosion-proof electric hoist: This type of hoist is designed for use in hazardous environments where there is a risk of explosion due to the presence of flammable gases or vapors. It is constructed with special materials and features that prevent sparks from being generated during operation, reducing the risk of ignition.

- GD(CD)—Low Headroom Single Speed Electric Hoist: This type of hoist is designed for use in areas with limited headroom, where a traditional hoist would not fit. It has a compact design that allows it to be installed in areas with low ceilings or other obstructions.

- GSD(MD)—low headroom two-speed electric hoist: This type of hoist is similar to the GD(CD) hoist, but has two lifting speeds and is suitable for applications where precise load control is required.

All of these types of electric wire rope hoists offer several advantages, including:

- They are available in a range of lifting capacities to meet specific application requirements.

- They offer precise load control and can be used to move materials in a variety of directions.

- They can be operated remotely, which increases operator safety and allows for greater flexibility in operation.

- However, each type of hoist also has its own unique features and limitations, which should be considered when selecting the appropriate hoist for a particular application.

Marking explanation:

Take a metallurgical electric hoists for example. If the required specifications are as following:

- The rated lifting capacity is 5 ton.

- The lifting height is 12m, and

- the working duty of metallurgical use trolley travelling electric wire rope hoist is M6.

The electric hoist with above specifications shall be marked as: YH 5t-12m M6

Cd/md

Low headroom

Explosion proof

Metallurgical

Fixed wire rope hoist

Double hook

Monorail Hoists and Monorail Crane System

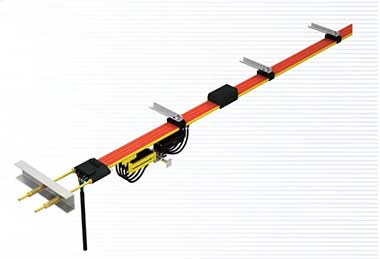

Monorail hoists and monorail cranes are types of material handling equipment that are commonly used in manufacturing and industrial settings.

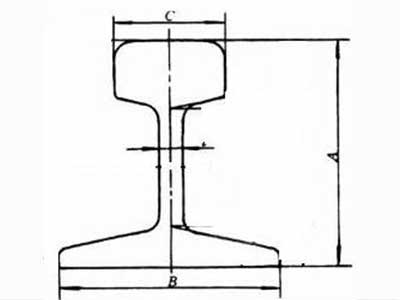

A monorail hoist is a type of hoist that runs on a single rail or beam, while a monorail crane consists of a single girder bridge that runs on a single rail or beam.Molds and dimensions of I beams-P15 14.2kg/m , P18 17.2kg/m, P22 21.2kg/m, P24 23.2kg/m , P30 28.2kg/m ,P38 37kg/m ,P43 42.3kg/m,QU70 51kg/m , QU80 61.3kg/m, QU100 84.3kg/m , QU120 113kg/m .

There are several types of monorail cranes, including:

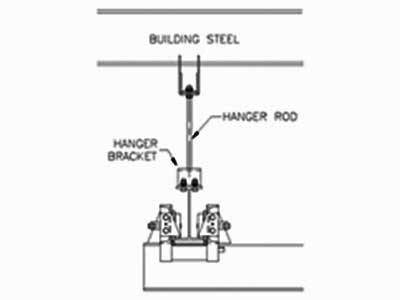

- Underhung Monorail Crane: This type of monorail crane is suspended from the building structure and runs on a single rail or beam.

- Top Running Monorail Crane: This type of monorail crane runs on a single rail or beam that is supported by columns or other structures.

- Single Girder Monorail Crane: This type of monorail crane consists of a single girder bridge that runs on a single rail or beam.

Features of monorail cranes include:

- They require less space than traditional overhead cranes.

- They can be customized to fit specific applications.

- They can be used to move materials in a straight line or along a curved path.

- Advantages of monorail cranes include:

- They are cost-effective and require less maintenance than traditional overhead cranes.

- They can be used in areas with limited space.

- They can be used to move materials in a variety of directions.

- Limitations of monorail cranes include:

- They have lower lifting capacities than traditional overhead cranes.

- They may not be suitable for applications that require high-speed or long-travel movements.

- They may require additional support structures to be installed in the building.

Ceiling mounted monorail cranes with H beam

Ceiling mounted monorail crane with curved beam

Straight monorail crane with european style hoist

Freestanding monorail cranes

U shape monorail rail

Curved monorail rail

Your Trusted Overhead Crane Manufacturer & Supplier

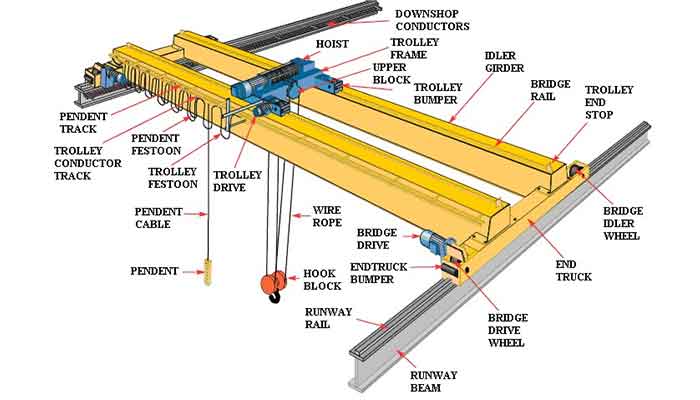

Bridge Cranes

Single / Double Girder & Top Running / Underhung Crane

Bridge cranes, also known as overhead cranes, are a type of material handling equipment that are commonly used in industrial and manufacturing settings. They consist of a bridge or beam that spans the width of a building, and one or more hoists that move along the bridge to lift and move heavy loads.

Main types of bridge cranes

Bridge cranes can be classified into different classifications based on different standards. In the following, main types of overhead crane types are presented for your reference.

1. According to overhead crane structure: There are single-girder bridge crane type, double-girder bridge crane type, multi-girder bridge crane such as four girder crane for casting industry, double trolley bridge type, and multi hoist and trolley bridge crane type, etc.

2. According to the pick-up device/ below-hook-devices: They can be classified hook bridge crane, grab bridge crane, electromagnetic bridge crane, container bridge crane, etc.

3. According to the purpose or applications: There are general bridge crane, metallurgical bridge crane, explosion-proof bridge crane and so on.

Single girder & Double Girder Bridge Cranes

Single girder bridge cranes

Single Girder Cranes - The crane consists of a single bridge girder supported on two end trucks. It has a trolley hoist mechanism that runs on the bottom flange of the bridge girder.

Basic structure of Chinese style electric single girder crane

- Bridge frame with operating mechanism and electric hoist moving along the lower flange of main beam which consisted of U shaped box girder and I beam steel.

- Electric hoist - is used for lifting heavy objects and running along the main beam, which is used as the lifting trolley of the bridge crane.

- Composition: bridge frame + crane running mechanism + electric hoist + electrical equipment.

- Features: Large lifting capacity, high working speed and high production efficiency.

- Main specifications - 1-20 ton

The advantages of double girder overhead cranes include high lifting capacity, increased height, greater stability, customizability, and versatility. Additionally, overhead cranes do not require floor space, making them ideal for industrial settings with limited space.

Main types of Single Girder Overhead Crane

The main types and moldes of bridge cranes in China are marked with the following:

- LD - electric single beam crane (LDA)

- LX— electric single girder suspension crane

- LB— Explosion-proof electric single beam crane

- LDY—Metallurgical Electric Single Girder Crane

- SL— Manual Single Beam Crane

- SLX—Manual Single Girder Suspension Crane

- LDP -low headroom single girder overhead crane

- LDE - Single girder overhead crane with double hoist trolley

- LZ - Single girder overhead crane with grab bucket

- HD- single girder overhead crane with European style design

- NLX -European type single girder suspension overhead crane

Double girder bridge crane

Double Girder Bridge Cranes - The crane consists of two bridge girders supported on two end trucks. The trolley runs on rails on the top of the bridge girders.

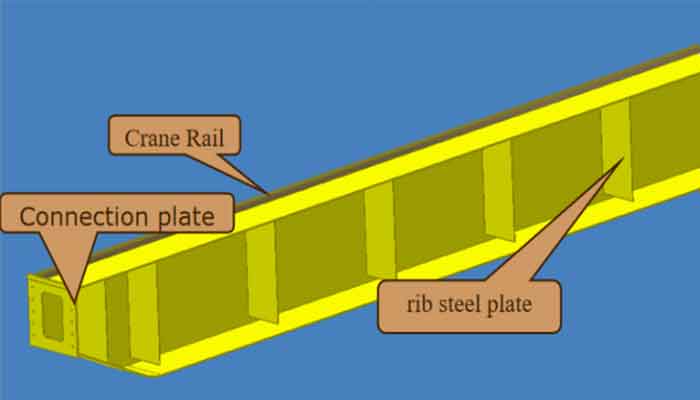

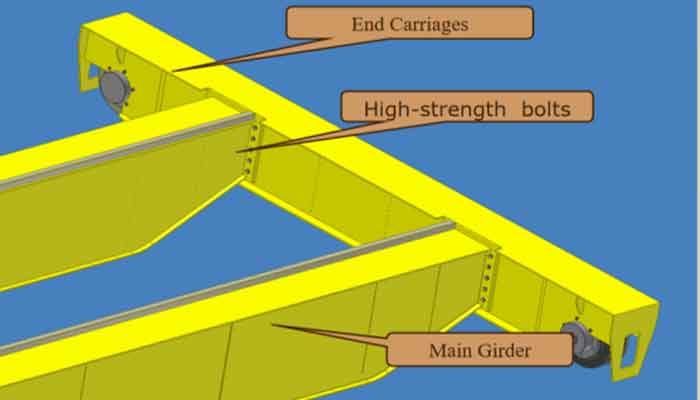

Main structure of double girder bridge crane

- Generally, it consists of a bridge frame, a crab hoist trolley running mechanism, a lifting trolley mechanism (with a lifting system and travelling trolley system ), crane operating system and electrics, etc.

- The double beam bridges are mainly consisted of main girder, end girder, trolley running track, railing, walking platform, driver's cab, etc.

- It is the main component of the bridge crane,which bears various loads, and should have sufficient rigidity and strength. Strength is the ability to resist fracture, and stiffness is the ability to resist deformation.

- Features - Material: Q235B or Q345B , Structural form: box type

- Main specification- 1 -320 ton

Because the main girder of the box structure has many advantages such as high overall rigidity, good manufacturing, assembly, transportation and maintenance conditions,and it is widely used at home and abroad.

Main types of overhead cranes

The main types and molds of bridge cranes made in China are marked as the following :

- LH— electric hoist bridge crane ( Comparied with Euroepan type electric hoist overhead crane )

- QD— Hook Overhead Crane (Universal Overhead Crane) ( Comparison with European type double girder overhead crane )

- QDY—casting bridge crane

- QZ— Grab bridge crane

- QB— Explosion-proof bridge crane

- QE— double trolley hook bridge crane

- QY— insulated bridge crane

- QC— Electromagnetic Bridge Crane

- QG— Hanging girder bridge crane

- QL— Electromagnetic hanging beam bridge crane

- SQ— Manual Double Girder Crane

- LHB—Explosion-proof electric hoist bridge crane

Types of traditional single girder overhead crane economical price

Crane type:LDA

Lifting capacity:1-20ton

Lifting height6-30m

Crane span:7.5-28.5m

Working class:A3-A5

Crane type:LX

Lifting capacity:0.5-10ton

Lifting height6、9、12、18m

Crane span:3-16m

Working class:A3-A5

Crane type:LB

Lifting capacity:1-16ton

Lifting height6、9、12、18、24m

Crane span:7.5-28.5m

Working class:A3

Crane type:LX explosion proof overhead crane

Lifting capacity:0.5-10ton

Lifting height6、9、12、18m

Crane span:3-16m

Working class:A3

Crane type:LDY

Lifting capacity:1-10ton

Lifting height9、12、15、18、20m

Crane span:7.5-28.5m

Working class:A6

Crane type:LDP

Lifting capacity:3~10ton

Lifting height6、9、12m

Crane span:7.5-22.5m

Working class:A3、A4

Crane type:LDE

Lifting capacity:(5+5)ton(10+10)ton

Lifting height6、9、12、18、24、30m

Crane span:7.5-22.5m

Working class:A3

Crane type:SL

Lifting capacity:1-5ton

Lifting height1-6m

Crane span:1-10M

Working class:A3

Crane type:LDZ

Lifting capacity:3-10ton

Lifting height9、12、15、18、20m

Crane span:4.5-28.5m

Working class:A5

Types of Chinese type double girder bridge cranes, reliable and cost-effective

Crane type:LH

Lifting capacity:5、10/3、16/3、20/5、32/10ton

Lifting height6、9、12、18、24、30m

Crane span:7.5-25.5m

Working class:A3-A5

Crane type:QD

Lifting capacity:5-450ton

Lifting height26m

Crane span:10.5-31m

Working class:A5、A6

Crane type:QB

Lifting capacity:5-75ton

Lifting height14-22m

Crane span:10.5-31.5m

Working class:A4

Crane type:QE

Lifting capacity:5-16ton

Lifting height16m

Crane span:10.5- 31.5m

Working class:A5、A6

Crane type:QDY

Lifting capacity:< 75ton

Lifting height20m

Crane span:10.5-31.5m

Working class:A7

Crane type:QZ

Lifting capacity:5、10、16、20ton

Lifting height18、20、26、28m

Crane span:10.5-31.5m

Working class:A6

Crane type:QC

Lifting capacity:5-32/5ton

Lifting height18m

Crane span:10.5-31.5m

Working class:A6

Crane type:QL

Lifting capacity:(5+5)-(20+20)ton

Lifting height12-16m

Crane span:10.5-31.5m

Working class:A6、 A7

Crane type:QN

Lifting capacity:5、10、16ton

Lifting height22m

Crane span:10.5-31.5m

Working class:A6

Under Running (U/R) & Top Running (T/R) Bridge Travelling Cranes

Top running vs. underhung

This is the section of the bridge where the trolley and hoist system is installed and operates.

- Top-running configurations -Due to the fact that the trolley and hoist are supported by the runway support columns, top-running configurations are perfect for lifting extremely heavy loads.

- Under hung crane configurations - In an underhung configuration, the trolley and hoist are connected and run along the bridge's lower flange. Underhung trolley and hoist configurations are an excellent way to maximize space in your facility.

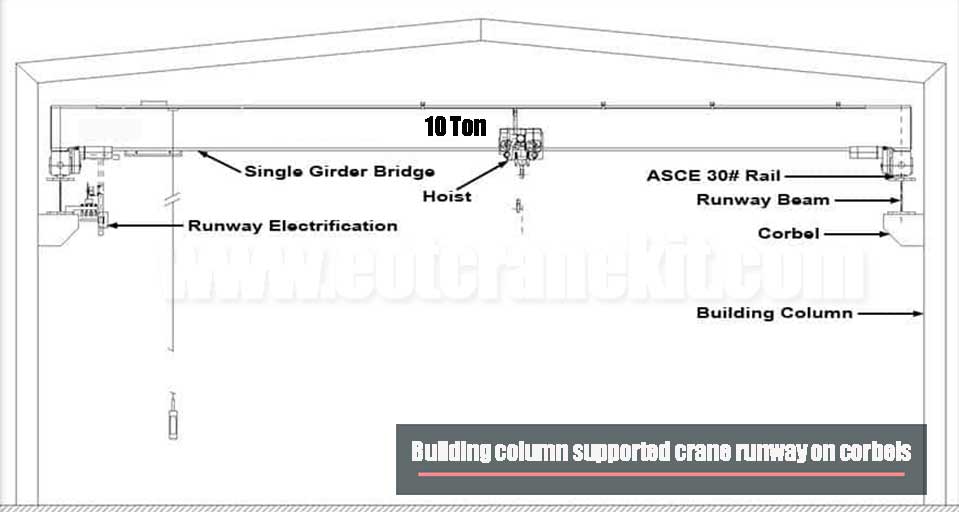

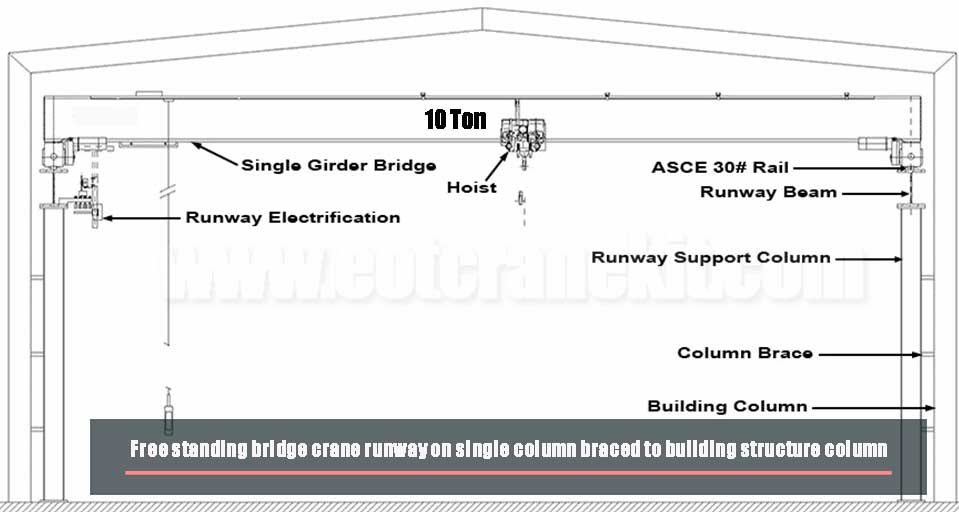

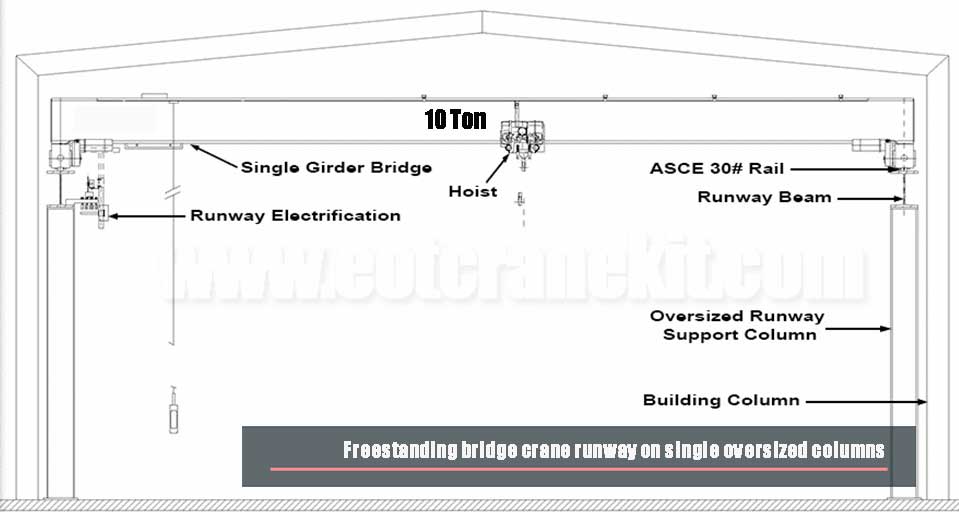

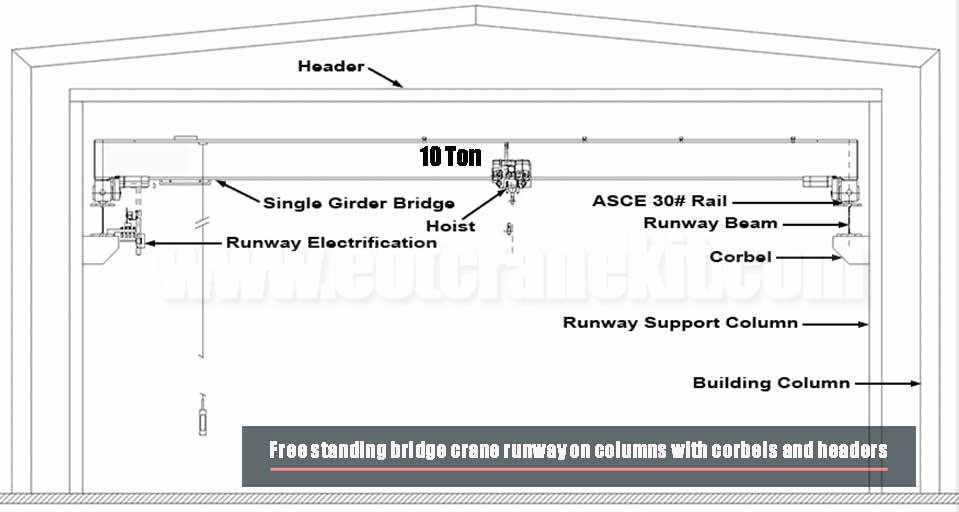

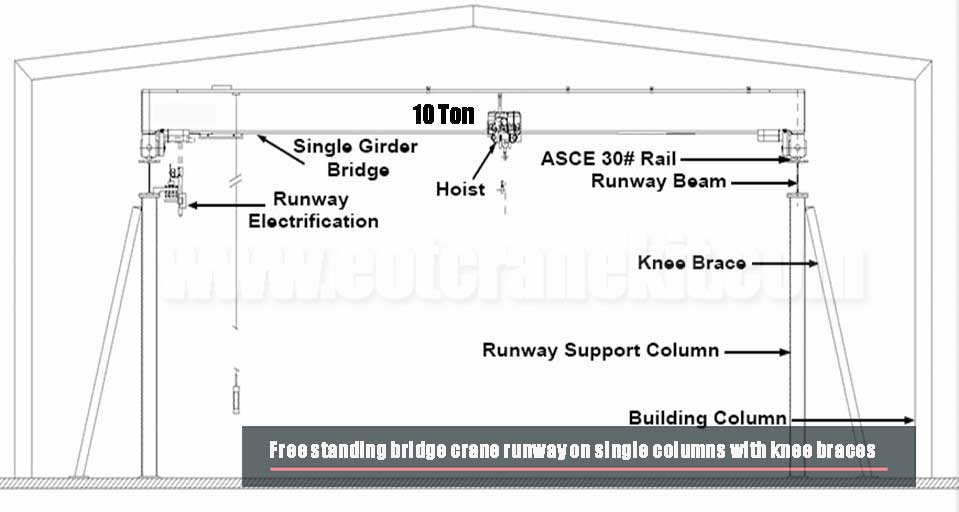

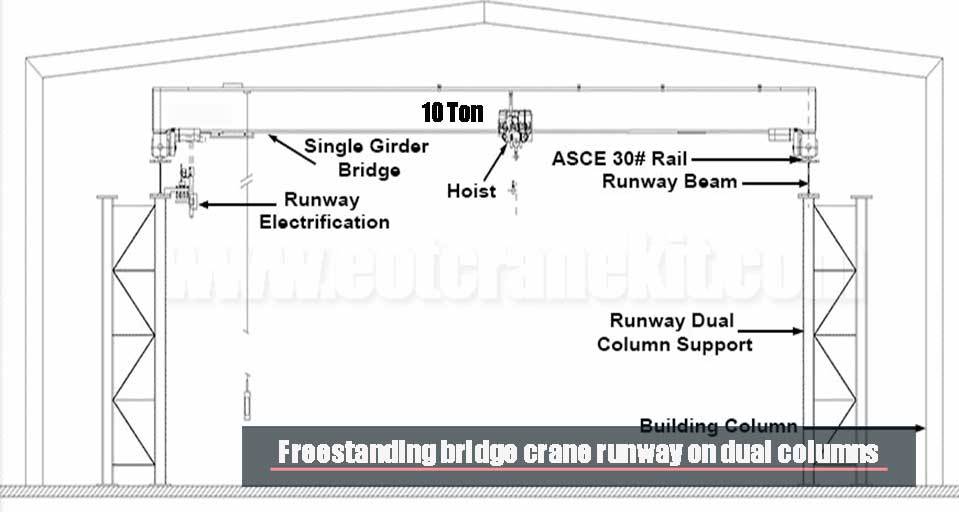

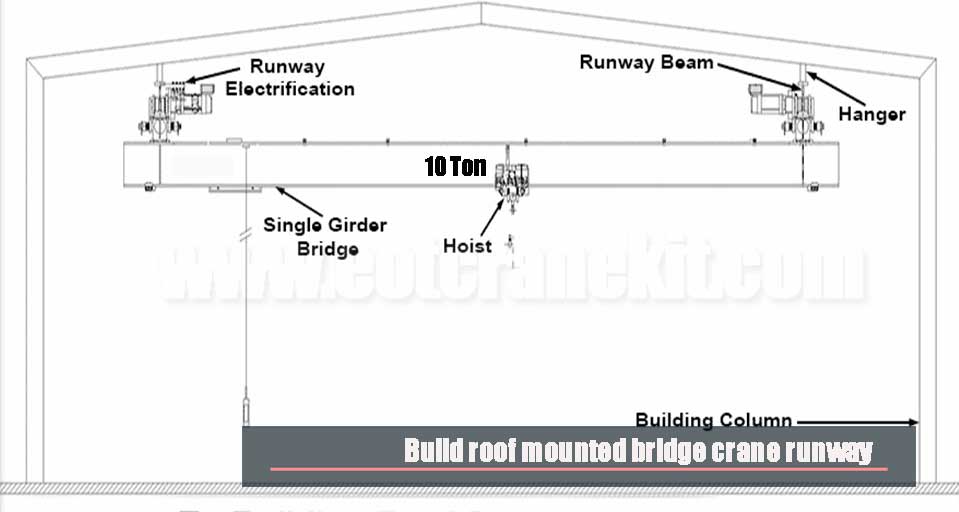

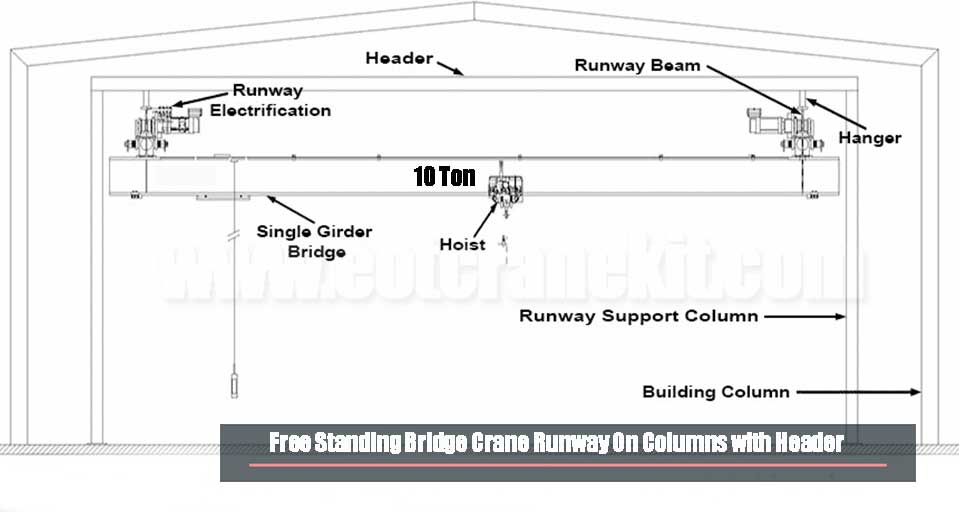

Top Running Cranes

Oveview - The crane bridge travels on top of rails mounted on a runway beam supported by either the building columns or columns specifically engineered for the crane. Top running canes are the most common form of crane design where the crane loads are transmitted to the building columns or free standing structure. These cranes have the greatest variation in capacity, span and service class and usually span the full width of the framing supports. These are available in both single girder and double girder configuration.

Basic structure of single girder top running crane

A top running single girder overhead crane is a type of crane that has a single beam spanning the width of a building and is supported by two end trucks. The hoist and trolley run on the bottom flange of the beam.

Advantages of a top running single girder overhead crane include:

- Cost-effective: Single girder cranes are generally less expensive than double girder cranes.

- Space-saving: Single girder cranes take up less space than double girder cranes, making them ideal for smaller facilities.

- Ease of maintenance: Because there is only one girder, maintenance is generally easier and less time-consuming.

Limitations of a top running single girder overhead crane include:

- Lower capacity: Single girder cranes typically have a lower capacity than double girder cranes.

- Limited span: Single girder cranes are typically limited in span compared to double girder cranes.

- Limited lift height: Single girder cranes may not be able to lift loads as high as double girder cranes.

Under running cranes

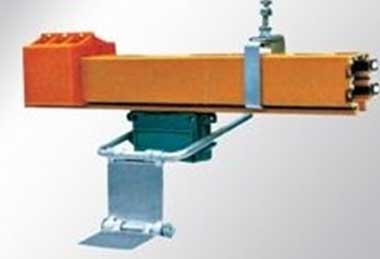

Overview - Under running or under slung cranes are supported by using a suspension type support which is connected to the bottom of the frame. The crane wheels are supported from the bottom of flange of the crane beams which act as a crane rail and usually only span a portion of the column-to-column span of the structure. Under running cranes are typically available in standard capacities up to 10 tons (special configurations up to 25 tons and over 90 ft spans). Under hung cranes offer excellent side approaches, close headroom and can be supported on runways hung from existing building members if adequate.

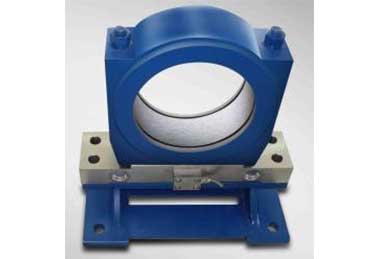

Basic structure of electric single girder suspension crane

The underhung bridge crane is basically similar to the top running electric single-girder crane. The main difference is that the underrunning crane is not supported and travelling on the top of runway beams between the spans of the building, but is suspended on the lower flange of the I-beam by using four pulleys mounted on the beam.

Advantages:

- simple structure, light weight, cheap price.

- And they can be installed on the ceiling or roof structure and used in relatively low factory buildings or warehouses, which is an cost-effective bridge crane by saving the cost of the crane supporting columns.

Limitations:

- There must be a roof truss or beam of sufficient strength to bear the self-weight, lifting load and dynamic load of the crane, so the lifting capacity of this underslung bridge crane should not be too large.

- At present, the maximum lifting capacity of undehrung bridge crane made by Chinese crane manufacturers and supplier are 10 ton.

Bridge cranes types based on the lifting devices

According to the pick-up device: such as hook bridge crane, grab bridge crane, electromagnetic bridge crane, container bridge crane, etc.

Overhead cranes are a type of material handling equipment that are used to lift and move heavy loads in manufacturing and industrial settings. There are several types of overhead crane attachments that can be used to increase the versatility and functionality of these cranes. Here are some examples:

Hook

grab

magnets

c hook

Spreader

- Hook Block: This is a basic attachment that is used to lift loads using a hook. Hook blocks are available in a range of sizes and capacities to meet specific application requirements.

- Lifting Magnets: These attachments use magnetic force to lift and move ferrous materials, such as steel plates or sheets. They are commonly used in metalworking and fabrication applications.

- Grabs: These attachments are used to lift and move bulk materials, such as sand, gravel, or scrap metal. They come in a variety of designs, including clamshell grabs, orange peel grabs, and bucket grabs.

- C-Hooks: These attachments are used to lift and move coils or other cylindrical loads. They are designed with a curved shape that allows them to securely grip the load.

- Spreader Beams: These attachments are used to distribute the weight of a load evenly across multiple lifting points. They are commonly used in applications where a load is too long or awkwardly shaped to be lifted with a single attachment point.

- Vacuum Lifters: These attachments use suction cups or a vacuum to lift and move materials, such as glass or plastic sheets. They are commonly used in manufacturing and assembly applications.

- Pallet Lifters: These attachments are used to lift and move pallets or other large containers. They are designed with fork-like tines that can be inserted into the pallet or container.

- Each type of overhead crane attachment offers its own unique advantages and limitations, and should be selected based on the specific requirements of the application.

Types of overhead cranes based on the uses or functions

According to the purpose or functions of cranes, the bridge cranes can be classified into general use bridge crane, metallurgical bridge crane, explosion-proof bridge crane and so on.

Overhead crane types | Classification | Application |

General overhead crane | Hook overhead crane, grab bridge crane, electromagnetic bridge crane, 2- purpose overhead crane, 3- purpose overhead crane | Machining workshop, assembly workshop, power plant, warehouse, storage yard |

Metallurgical bridge crane | Casting bridge crane, clamp crane, ingot stripping crane, feeding crane and forging crane | Steel Plant |

Explosion-proof bridge crane/ Hazardous use overhead cranes | Explosion-proof bridge crane for coal mine; explosion-proof bridge crane for factory | Coal mines, factories with flammable and explosive mixtures |

Your Trusted Overhead Crane Manufacturer & Supplier

Gantry Crane

Main types of gantry cranes

With gantry cranes, the trolley and hoist mechanism still travels along a bridge but is supported by legs rather than runways. They are therefore perfect for outdoor situations where installing columns is not an option. For instance, fixed- or track-mounted gantry cranes are frequently utilized for those applications in shipyards and railyards.

Gantry cranes are adaptable and come in portable and adjustable models. Gantry cranes are especially helpful in situations where lifting is not usually needed, like in a motor repair shop, etc.

Main types of gantry cranesBased on different classifications standards, the gantry cranes can be classified into different crane types:

There are many classifications of gantry cranes:

- 1. According to the structure: single main girder gantry crane, double main girder gantry crane, box type or truss type gantry crane.

- 2. According to the cantilever: single cantilever gantry crane, double cantilever, no cantilever gantry crane, etc.

- 3. According to the support method: rail-mounted gantry cranes, tire-type gantry cranes.

- 4. According to the pick-up device: hook gantry crane, grab gantry crane, electromagnetic gantry crane, etc.

- 5. According to the application occasion: general purpose gantry crane, shipbuilding gantry crane, hydropower station gantry crane, etc.

Single girder gantry crane & double girder gantry cranes

A single girder gantry crane is a type of gantry crane that has a single main girder spanning between two legs. It is commonly used in outdoor applications, such as in shipyards, construction sites, and storage yards.

Features of a single girder gantry crane include:

- Cost-effective: Single girder gantry cranes are typically less expensive than double girder gantry cranes, making them a cost-effective solution for many outdoor lifting applications.

- Versatile: Single girder gantry cranes can be designed to handle a wide range of load capacities and sizes, making them suitable for a variety of applications.

- Easy to install: Single girder gantry cranes are typically easier to install than other types of cranes, such as bridge cranes or jib cranes.

- Space-saving: Single girder gantry cranes take up less space than other types of cranes, such as bridge cranes or jib cranes. This makes them ideal for use in areas where space is limited.

- Mobility: Single girder gantry cranes can be mounted on wheels or rails for mobility, allowing them to be easily moved between work areas.

Overall, single girder gantry cranes are a versatile and cost-effective solution for many outdoor lifting applications. They offer a range of features and can be customized to meet the specific needs of a particular application.

Types of single girder gantry crane

- The symbols are: MDG, MDE, MDZ, MDC, MDN, MDP, MDS, MH, MBH

- Such as: MDG- single girder single trolley hook gantry crane

- MDE- Single girder double trolley hook gantry crane

- MDZ- Single Beam Grab Gantry Crane

- MDC- Single Beam Electromagnetic Gantry Crane

- MDN—single girder single trolley grab hook gantry crane

- MDP-S ingle Beam Grab Electromagnetic Gantry Crane

- MDS—Single girder three-purpose gantry crane

- MH— electric hoist gantry crane

- MBH-Electric hoist semi-gantry crane

- Portable gantry crane - Fixed height & adjustable height gantry cranes

Double girder gantry cranes are heavy-duty cranes that are used to lift and move large and heavy objects in industrial settings such as factories, shipyards, and construction sites.

Features of double girder gantry cranes include:

- High lifting capacity: Double girder gantry cranes have a higher lifting capacity than single girder gantry cranes, making them ideal for lifting and moving heavy loads.

- Increased height: The double girder design allows for a higher hook height, which is beneficial for lifting and moving objects that require additional clearance.

- Greater stability: Double girder gantry cranes are more stable than single girder gantry cranes, which allows for greater precision during lifting and movement.

- Customizable: Double girder gantry cranes can be customized with various lifting attachments and safety features to meet specific industrial needs.

- Versatile: Double girder gantry cranes can be used in both indoor and outdoor settings, making them a versatile option for various industries.

Double girder gantry cranes have several advantages, including high lifting capacity, increased height, greater stability, customizability, and versatility. These features make them an ideal choice for lifting and moving heavy loads in various industrial settings.

Types of Double girder gantry crane

- The symbols are: MG, ME, MZ, MC, MP, MS, RMG, RTG

- Such as: MG—double girder single trolley hook gantry crane

- ME—Double girder double trolley hook gantry crane

- MZ- double girder grab bucket gantry crane

- MC-Double beam electromagnetic gantry crane

- MP- Double Beam Grab Electromagnetic Gantry Crane

- MS- Double girder three-purpose gantry crane

- RMG- Rail Mounted Container Gantry Crane

- RTG-Tire Type Container Gantry Crane

Types of gantry cranes based on gantry supporting legs

Crane type:MH

Lifting capacity:3-16ton

Lifting height9m

Crane span:12-30m

Working class:A3

Crane type:MG

Lifting capacity:Up to 500ton

Lifting height12m

Crane span:18-35m

Working class:A5

Crane type:MHZ

Lifting capacity:5-10ton

Lifting height9m

Crane span:12-30m

Working class:A5

Crane type:MDG

Lifting capacity:5-32/5ton

Lifting height11m

Crane span:18-35m

Working class:A5

Crane type:MZ

Lifting capacity:5ton、10ton

Lifting height18m

Crane span:18-35m

Working class:A6

Crane type:L

Lifting capacity:5-10ton

Lifting height9m

Crane span:16-30m

Working class:A5

Crane type:MHE

Lifting capacity:(1+1)-(20+20)ton

Lifting height7.5-22m

Crane span:5-20m

Working class:A3-A5

Crane type:MHB

Lifting capacity:5-10ton

Lifting height6m

Crane span:10-20m

Working class:A4

Crane type:BMH

Lifting capacity:5-10ton

Lifting height6m

Crane span:10-20m

Working class:A4

Crane type:Portable gantry crane

Lifting capacity:1-5ton

Lifting height6m

Crane span:10m

Working class:light duty

- A-frame gantry crane type: This type of gantry crane has two vertical A-shaped legs that are connected at the top by a horizontal beam. The trolley, which carries the load, runs along the horizontal beam. This design offers high stability and is suitable for heavy-duty lifting applications.

- U-shaped gantry crane type: This type of gantry crane has two parallel legs that are connected by a U-shaped cross beam. The trolley runs along the bottom flange of the cross beam, and the U shape of the beam provides additional stability. This design is suitable for heavy-duty lifting applications where stability is important.

- L-shape leg gantry crane type: This type of gantry crane has two legs that are shaped like an L. The trolley runs along the bottom flange of the cross beam, and the L shape of the legs provides good stress conditions. This design is suitable for applications where there is limited space for goods to pass through horizontally.

- C-type gantry crane type: This type of gantry crane has two legs that are shaped like a C. The trolley runs along the bottom flange of the cross beam, and the C shape of the legs provides a large horizontal passing space. This design is suitable for applications where there is a need for a large horizontal passing space.

- Semi-gantry crane/single leg gantry crane type: This type of gantry crane has one end of the main beam supported by a vertical leg, while the other end is supported by a runway on the ground. The trolley runs along the bottom flange of the main beam. This design is suitable for applications where there is limited space for installation.

- Truss type gantry cranes: This type of gantry crane has a main beam that is constructed with truss members. The trolley runs along the bottom flange of the main beam, and the truss design provides high strength and stability. This design is suitable for heavy-duty lifting applications.

- Each structural form of gantry crane offers its own unique advantages and limitations, and should be selected based on the specific requirements of the application. Factors to consider when selecting a gantry crane include lifting capacity, span, height, mobility, and support structure for installation.

Selection of Gantry Cranes

1. Selection of single main girder and double girder gantry cranes

Choose according to the lifting tonnage, working speed and cargo size.

- The single main girder type is used when the span is less than 35 meters and there is no special requirement under 50 tons.

- Double-girder type is used when the width of the door foot is large, the working speed is high, or long pieces are often lifted.

2. Span and cantilever length - According to the main factors affecting the crane's self-weight, the span should be kept as small as possible while meeting other requirements.

3. Determination principle of wheelbase - Meet stability requirements; Transverse passability of goods; General wheelbase B=(1/4~1/6)S.

4. Determination of the distance between gantry cranes

During work, there should be a certain space between the external dimensions of the gantry crane and the cargo and transport vehicle passages in the yard to facilitate loading and unloading operations. Generally, when the transport vehicles are loaded and unloaded within the span, there should be a distance of more than 0.7m from the door legs. There should be a distance of more than 0.5m between the spreader and the transport vehicle when it is not working, and a distance of more than 0.5m when the goods pass through the door legs.

Your Trusted Overhead Crane Manufacturer & Supplier

Jib Crane & Cantilever Crane

Main types of jib cranes

Jib cranes are ideal for areas with insufficient headroom and structural support, providing versatile and cost-effective lifting solutions. Jib cranes have limited movement because they cannot move around a facility, but they can be used as supplements to regular traveling cranes and monorail tracks. They can also be used in bays, as well as along the walls and sides of stores. Jib cranes provide 180- or 360-degree movement when mounted to the floor or a wall.

Floor jib crane

Wall jib cranes

Advantages of jib cranes include:

- Versatility: Jib cranes are available in a range of sizes and lifting capacities, making them suitable for a variety of applications. They can be used to lift and move loads in a variety of directions, making them ideal for applications where precise load placement is required.

- Space-saving: Jib cranes take up less floor space than other types of cranes, such as bridge cranes or gantry cranes. This makes them ideal for use in areas where space is limited.

- Cost-effective: Jib cranes are generally less expensive than other types of cranes, making them a cost-effective solution for many applications.

- Easy to install: Jib cranes can be installed quickly and easily, often with minimal disruption to existing operations.

- Increased safety: Jib cranes can be operated remotely, which increases operator safety and reduces the risk of accidents. They also offer precise load control, which reduces the risk of damage to the load or surrounding equipment.

- Overall, jib cranes are a versatile and cost-effective solution for many material handling applications. They offer several advantages over other types of cranes, including space-saving design, easy installation, and increased safety.

Limitations of jib cranes

- While jib cranes offer several advantages, they also have some limitations that should be considered when selecting the appropriate material handling equipment for a particular application. Some limitations of jib cranes include:

- Limited lifting capacity: Jib cranes typically have a lower lifting capacity than other types of cranes, such as bridge cranes or gantry cranes. This makes them unsuitable for applications that require lifting very heavy loads.

- Limited reach: Jib cranes have a limited reach compared to other types of cranes. This means that they may not be suitable for applications where the load needs to be moved over a large distance.

- Limited mobility: Jib cranes are typically mounted in a fixed location and cannot be moved easily. This means that they may not be suitable for applications where the load needs to be moved to different locations within a facility.

- Limited height: Jib cranes are typically mounted at a fixed height, which may not be suitable for applications where the load needs to be lifted to a great height.

- Space limitations: While jib cranes are space-saving compared to other types of cranes, they still require a certain amount of space for installation. This means that they may not be suitable for applications where space is extremely limited.

Overall, jib cranes are a versatile and cost-effective solution for many material handling applications. However, their limitations should be carefully considered when selecting the appropriate equipment for a particular application.

Crane type:BZD pillar jib crane

Lifting capacity:0.125-5ton

Lifting height3m

Arm length:3-6m

Lifting height:2-8m/min

Crane type:BX wall mounted jib crane

Lifting capacity:0.125-3ton

Lifting height3m

Arm length:3-6m

Lifting height:2-8m/min

Crane type:BB wall travelling jib crane

Lifting capacity:1-5ton

Lifting height: As request

Arm length:4-12m

Lifting height:8m/min

Crane type:Articulating jib crane

Lifting capacity:0.125-0.5ton

Lifting height3m

Arm length:3-4m

Lifting speed:2-8m/min

Crane type:Portable jib crane

Lifting capacity:0.125-0.5ton

Lifting height3m

Arm length:3m

Lifting height:8m/min

Crane type:Double arm jib crane

Lifting capacity:0.125-5ton

Lifting height3m

Arm length:3-5m

Lifting speed:2-8m/min

- Freestanding pillar jib crane: This type of jib crane is mounted on a freestanding pillar or column, which provides support and stability. It is commonly used in outdoor applications, such as loading docks or construction sites.

- Foundationless jib cranes: This type of jib crane does not require a foundation or concrete pad to be installed. Instead, it is mounted directly to the existing floor or concrete slab. It is commonly used in applications where a permanent foundation is not practical or cost-effective.

- Wall-travelling jib crane: This type of jib crane is mounted on a track that allows it to move horizontally along a wall or other structure. It is commonly used in applications where space is limited or where a freestanding crane would not fit.

- Wall-mounted jib crane: This type of jib crane is mounted directly to a wall or other vertical structure. It is commonly used in manufacturing and industrial settings where a permanent lifting solution is required.

- Portable jib crane: This type of jib crane is designed to be moved from one location to another as needed. It is typically mounted on a wheeled base that allows it to be easily transported.

- Articulating jib crane: This type of jib crane has a flexible arm that can be adjusted to reach loads in tight or hard-to-reach spaces. It is commonly used in manufacturing and assembly applications where precise load placement is required.

Each type of jib crane offers its own unique advantages and limitations, and should be selected based on the specific requirements of the application. Factors to consider when selecting a jib crane include lifting capacity, reach, height, and mobility, as well as the available space and support structure for installation.

Your Trusted Overhead Crane Manufacturer & Supplier

Workstation Cranes & Cell Cranes

Main types of workstation bridge cranes

Workstation cranes provide a convenient and ergonomic design for repetitive activities and lightweight applications (up to 2 tons). Workstation cranes, which come in a wide range of sizes and lifting capacities, can be set up as over-hung systems or standalone buildings in your company, to assist enhance safety, uptime, and productivity in your business.

A workstation crane is a type of overhead crane that is designed to lift and move loads within a limited area, typically within a workstation or production cell. It is a smaller and more lightweight version of a traditional overhead crane, and is commonly used in manufacturing and assembly applications.

Freestanding workstation crane

Ceiling-mounted workstation crane

There are two main types of workstation cranes:

- Freestanding workstation crane: This type of workstation crane is mounted on a freestanding support structure, such as a column or post. It can be easily moved and repositioned as needed, and is ideal for applications where flexibility is important.

- Ceiling-mounted workstation crane: This type of workstation crane is mounted to the ceiling or roof structure of the building. It offers greater lifting capacity and can cover a larger area than a freestanding workstation crane, but requires a more permanent installation.

Advantages of workstation cranes include:

- Increased productivity: Workstation cranes allow operators to move loads quickly and easily, reducing the time and effort required for manual handling.

- Improved ergonomics: Workstation cranes can be designed to fit the specific needs of the operator, improving ergonomics and reducing the risk of injury.

- Increased safety: Workstation cranes can be operated remotely, which increases operator safety and reduces the risk of accidents. They also offer precise load control, which reduces the risk of damage to the load or surrounding equipment.

- Space-saving: Workstation cranes take up less floor space than other types of cranes, such as bridge cranes or gantry cranes. This makes them ideal for use in areas where space is limited.

Limitations of workstation cranes include:

- Limited lifting capacity: Workstation cranes typically have a lower lifting capacity than other types of cranes, such as bridge cranes or gantry cranes. This makes them unsuitable for applications that require lifting very heavy loads.

- Limited reach: Workstation cranes have a limited reach compared to other types of cranes. This means that they may not be suitable for applications where the load needs to be moved over a large distance.

- Limited mobility: Workstation cranes are typically mounted in a fixed location and cannot be moved easily. This means that they may not be suitable for applications where the load needs to be moved to different locations within a facility.

- Limited height: Workstation cranes are typically mounted at a fixed height, which may not be suitable for applications where the load needs to be lifted to a great height.

Overall, workstation cranes are a versatile and cost-effective solution for many material handling applications within a limited area. However, their limitations should be carefully considered when selecting the appropriate equipment for a particular application.

Your Trusted Overhead Crane Manufacturer & Supplier

How to Select The Best for Your Applications

Factors affect crane selection

The overhead crane in your plant is one of the most crucial pieces of machinery. The majority of the labor-intensive work at your facility is physically done by it, therefore you need to have the equipment that will perform optimally for your needs. The size of your facility and your budget are only two factors to consider when selecting an overhead crane. You must carefully choose because there are various things to take into account, including your facility and the applications you will use it for.

Here are some fundamental guidelines to help you choose the best overhead crane equipment for your organization.

What is your facility conditions?

Take a thorough look at your facilities and decide what size and type of cranes will fit into the space the best before you start looking into a specific cranes.

This includes:

- Calculating the area that the crane will cover. You must measure any height limits or obstructions on the ceiling that can affect the functioning of the crane or violate OSHA rules in addition to the width and length of your structure.

- identifying any barriers that might restrict the crane's mobility. Examine your facilities to identify any potential impediments that can prevent appropriate and safe operation. OSHA regulations provide for at least 3 inches of clearance above and 2 inches of clearance laterally around crane equipment.

knowing how to install the crane in your facility. You might be able to employ a portable system that doesn't need any installation depending on your applications and the layout of your facility. However, if you want the installation of a permanent system, pay special attention to whether your facility has the foundation and/or structure required for a secure installation.

What is your lifting requirements?

The application for which you will require the overhead crane is the next most crucial consideration after determining how a crane might fit into your building. When considering your options for cranes, keep the following in mind:

- Crane capacity and working duty. Pay special attention to the amount of weight a overhead crane can support and evaluate it against your requirements. Even marginally exceeding a crane's capacity can be exceedingly risky. Decide if your lifting crane will need to be put to everyday use because the service duty or working class also dictates how frequently the crane can be used safely.

- Structural components .Aluminum or steel can be used to make cranes, with steel being more robust and long-lasting. Steel construction cranes are typically required for heavier-duty applications.

- Mechanical and electrical systems.

Additionally, consider the crane's capabilities and whether they align with the application. Your crane may be able to provide more reach and better flexibility around obstructions, for example, thanks to systems like a telescoping bridge. Your staff may be able to multitask or control the crane remotely if necessary thanks to the operator controls.

There are numerous aspects to consider when picking the ideal overhead crane system for your requirements. It might be difficult to choose the appropriate overhead crane equipment for your facility and application, but being aware of your needs in advance can help you avoid a lot of uncertainty. Yuantai Crane has rich experience in helping clients to select the right type of cranes, hoists, and structures they require to improve worksing efficiency, safety and make more profits.

If you're looking for a new overhead crane system, get in touch with Yuantai Crane to see what we can do to help you.

Main Specifications, Definitions & Terms of Main Types of Cranes

Your Trusted Overhead Crane Manufacturer & Supplier

Main Specifications, Definitions & Terms of Main Types of Cranes

Overhead Crane Basic to know Better Your Overhead Crane Design & Solution

Basics of overhead crane specifications, definitions & terms for reference to get custom overhead crane, gantry crane, jib crane & other hoists and cranes.

Lifting capacity / Rated lifting capacity of crane

The lifting capacity or rated lifting capacity of a crane is commonly referred to as the lifting weight G. It refers to the maximum weight that a crane can lift safely and stably under normal working conditions. The lifting capacity of a crane is determined by its structural design, such as the length of its boom, the strength of its wire ropes, and the capacity of its hoisting mechanism. The lifting capacity is usually expressed in metric tons (t) or kilonewtons (kN).

- Rated lifting capacity Gn refers to the total weight of the material that the crane can lift along with any detachable lifting equipment or attachments such as grab buckets, electromagnetic suction cups, balance beams, etc.

- Total lifting capacity Gz refers to the total weight of the material that the crane can lift along with any detachable lifting equipment and fixed lifting equipment and devices that are permanently attached to the crane (including hooks, pulley blocks, lifting steel wire ropes, and other lifting devices below the crane trolley).

- Effective lifting capacity Gp refers to the net weight of the material that the crane can lift.

Note:The parameters need to be explained as follows:

- First, the lifting capacity marked on the crane nameplate usually refers to the rated lifting capacity of the crane, which should be prominently displayed on an obvious position of the crane structure.

- Second, for jib type cranes, the rated lifting capacity varies with the amplitude, and its lifting characteristic index is characterized by the lifting moment. The value marked on the label is the maximum lifting capacity.

- Third, for cranes with detachable spreaders (such as grab buckets, electromagnetic suckers, balance beams, etc.), the total rated lifting capacity of the spreader and the mass of the material, the mass of the material allowed to be lifted is the effective lifting capacity.

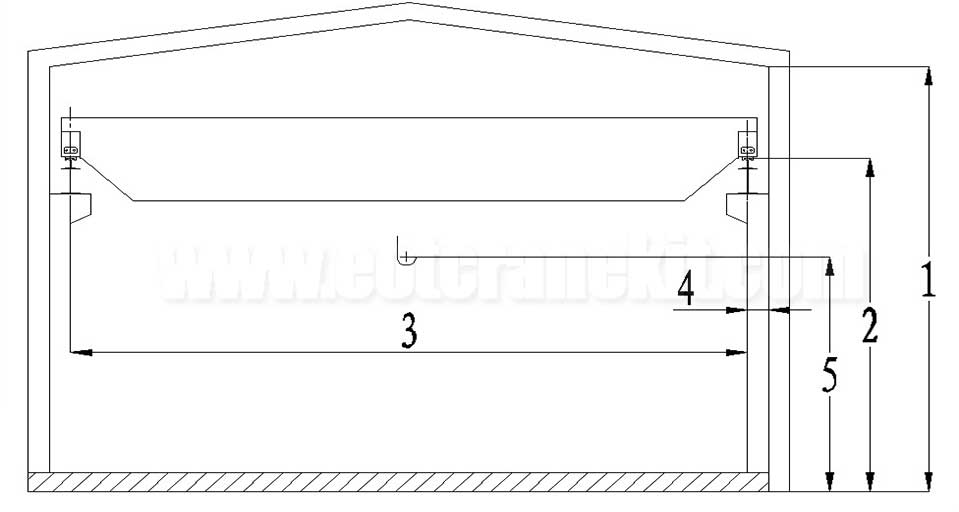

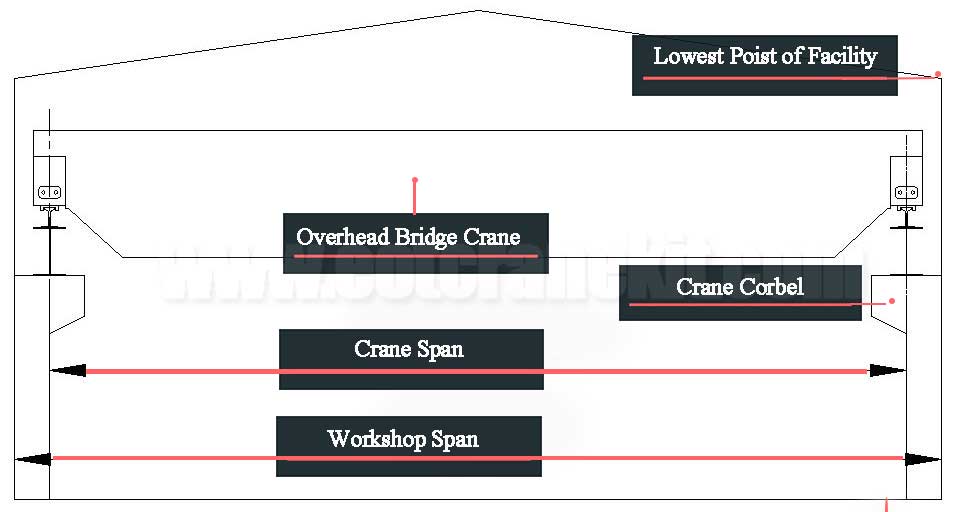

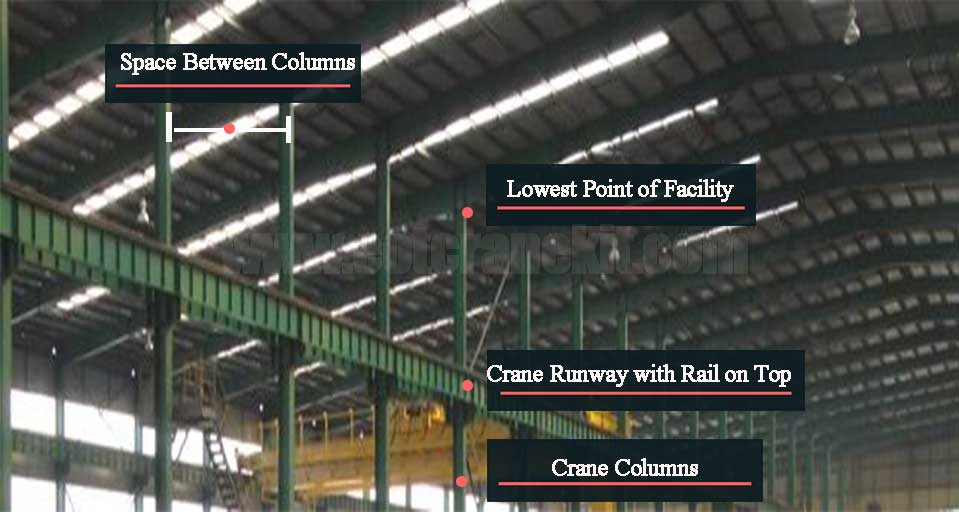

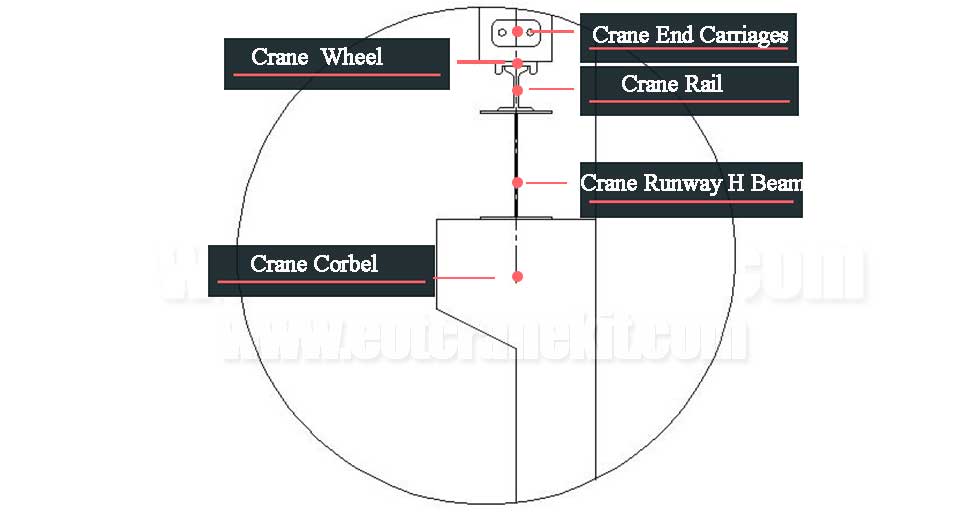

Crane span

- Crane span - Span S refers to the horizontal distance between the centerlines of the running tracks of a bridge-type crane, measured in meters. The span of a bridge crane is usually 1.5-2.0 meters smaller than the span of the building (1.5 meters for cranes under 50 tons).

- Bridge crane gauge - The distance between the centerlines of the running tracks of a bridge crane's trolley is called the gauge of the trolley.

- Gantry crane gauge The distance between the centerlines of the running tracks of a gantry crane that runs on tracks on the ground is called the gauge of the crane.

Lifting height

The lifting height H is the vertical distance from the top surface (or ground) of the crane running track to the uppermost position of the lifted load. The unit of measurement is meters. When using a hook, the measurement is taken to the center of the hook ring, while when using a grab bucket or other containers, the measurement is taken to the bottom of the container. More about crane crane span, lifting height and types of lifting crane working coverage for your reference.

- The vertical distance from the ground to the highest allowable position of the lifting device, marked as H.

- If the hook can be lowered below ground level, then the height below ground level is called the lowering depth (h).

- Long travel refers to the direction of the bridge's movement along the rails.

- Cross travel refers to the movement of the 'crab' from one side of the bridge to the other.

- Hook Height is the distance from the datum to the highest position of the hook, which determines the height of the runway from the floor and is dependent on the clear inside height of the building. Effective lift is the distance between the beam and the floor, minus the height of the hoist.

- Runway Height is the distance between the grade level and the top of the rail.

- Side Clearances are measured from the center of the supporting rail to the face of the supporting column, required for operation, safety, and wheel maintenance.

- Vertical Clearances refer to the space required for the crane to travel within a building while avoiding obstructions such as lights, equipment, and structural framing. The lower the crane headroom, the higher will be the vertical clearance and lower could be the building height.

- Clear Span is the horizontal center distance between the rails of the runway on which the crane travels, typically 500 mm less than the width of the building. The span required depends on the crane coverage width dictated by the application.

- Runway Length is the longitudinal run of the runway rail parallel to the length of the building.

- Hook Approaches refer to the distance from the wall to the nearest possible position of the hook, which affects floor area utilization.

- End Approach refers to the minimum horizontal distance parallel to the runway between the outermost extremities of the crane and the centerline of the hook.

- Bridge, Trolley, and Lift Speeds are specified in feet per minute or FPM and selected to allow safe operation while using a pendant. Dual operating speeds are commonly used, but a variable speed control system is preferred for optimum control.

- Electrical Requirements ideally include 480 volt, 3 phase, 60 hertz for US requirements. The runway power is usually by a conductor bar, and a hoisting trolley by festoon cable. The control circuit voltage at pendant pushbuttons shall not exceed 150 volts for AC and 300 volts for DC.

Radius R:

- For a jib crane in a horizontal position, the distance between the centerline of rotation and the vertical line passing through the center of the load.

- For a non-rotating jib crane, it refers to the distance between the pivot point under the jib and the vertical line passing through the center of the load.

- The maximum radius is achieved when the jib is at its minimum inclination or when the distance between the trolley position and the center of rotation of the crane is at its maximum.

Amplitude L

The amplitude of the rotating jib crane refers to the horizontal distance between the center line of rotation and the plumb line of the pick-up device, and the unit is m. The amplitude of a jib crane of the non-rotating type refers to the horizontal, horizontal distance between the centerline of the spreader and the rear axle of the jib or other typical axis.

When the inclination angle of the jib is the smallest or the distance between the position of the trolley and the center of rotation of the crane is the largest, the amplitude is the maximum amplitude; otherwise, it is the minimum amplitude.

Operating speed:

- Hoisting speed Vq refers to the vertical displacement speed of the rated load when the crane is in a stable operating state, measured in meters per minute.

- Trolley running speed Vk refers to the running speed of the crane with the rated load on a horizontal surface or track, measured in meters per minute.

- Crane running speed Vt refers to the running speed of the trolley with the rated load on a horizontal track in a stable motion state, measured in meters per minute.

- Slewing speed V1 refers to the average linear speed of the horizontal displacement from maximum radius to minimum radius in the slewing plane with the minimum rated load when the crane is in a stable motion state, measured in meters per minute.

- Traveling speed V refers to the smooth running speed of a mobile crane with a rated load while driving on a road, measured in kilometers per hour.

- Rotation speed ω refers to the rotation speed of the crane around its center of rotation when it is in a stable motion state, measured in revolutions per minute.

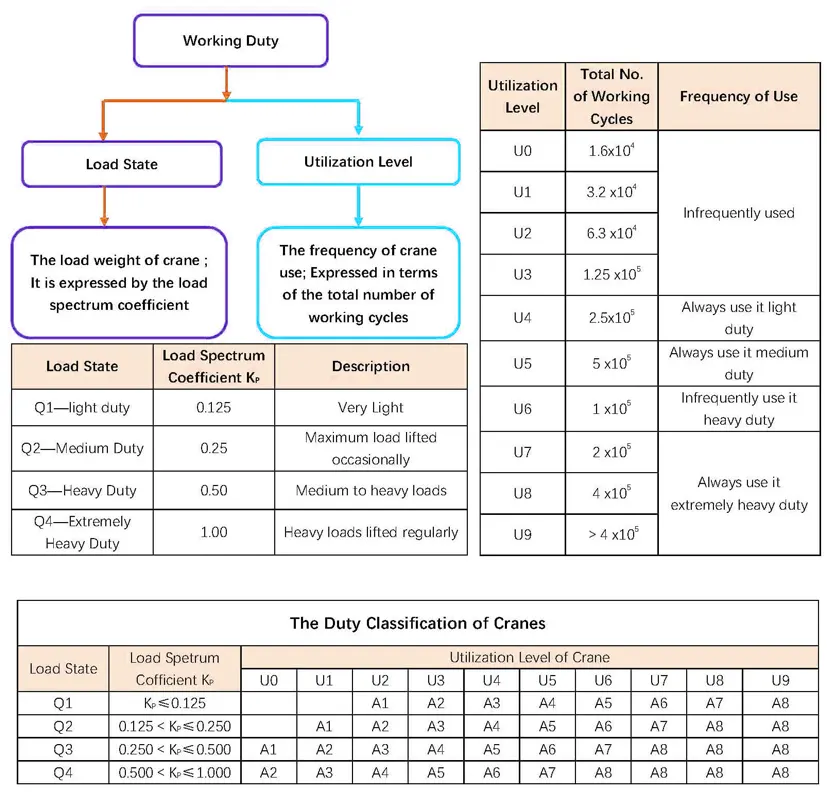

Working class or working duty of cranes

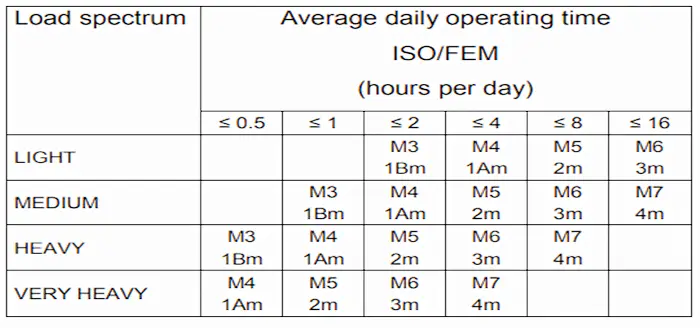

The working class of a crane is determined by considering the utilization of its lifting capacity and time, as well as the working characteristics of the operating cycles. According to GB/T 3811-2008 "Design rules for cranes," the working class of a crane is divided into the working class of the entire machine, the working class of the mechanism, and the working class of the structural or mechanical components.

The usage level of a crane (i.e., the degree of busyness over time) is classified into different levels based on the number of load cycles and the duration of the operation.

The crane use level indicates how frequently the crane was used over the design life. The general work cycle number N is divided into 10 levels based on the design life period (see table 1).

Crane use level | general work cycle number N | annotation |

U0 | 1.6*10 4 | Not often use |

U1 | 2.2*104 | |

U2 | 3.3*104 | |

U3 | 1.25*105 | |

U4 | 2.5*105 | Free to use |

U5 | 5*105 | Often secondary to use |

U6 | 1*106 | Don't always busy to use |

U7 | 2*106 | Busy use |

Crane load condition

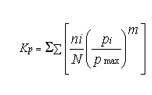

The degree of the crane load is determined by two factors: the ratio of hoisting the load to the rated load Pi/Pmax, and the ratio of the role of various hoisting load numbers to the general work cycles ni/N. The following are the two load spectrum factor and Kp computed by type relationships:

In the formula:

Kp—load spectrum factorand; ni—the effect number of load Pi; N—general work cycles, N= ; Pi—the I hoisting load, i=1,2….n; Pmax—max lifting load; m—index, in here m=3.

The nominal load spectrum coefficient divides the crane load condition into four categories (see table 2)

Table 2:

Crane load condition | nominal load spectrum coefficient (Kp) | Explain |

Q1-light | 0.125 | Rarely lifting load rating |

The load state level is classified into four levels: Q1, Q2, Q3, and Q4, with Q1 being the most frequently used and Q4 being the least frequently used. The load state level is determined based on the ratio of the actual weight of the lifted object to the rated lifting capacity of the crane.

One working cycle: hoisting goods/ loads→lifting→running→lowering→unloading→the empty hook returns to its original position.

The idle time between work cycles of a crane refers to the time required for the crane to complete one work cycle and return to its original position before starting the next work cycle. The idle time depends on the type and configuration of the crane, as well as the specific work environment.

Calculation formula for total working cycles: N=3600YDH/tc

Y: The service life of the crane (generally 20-30 years) .D: The number of working days in a year (265 days) H: The number of working hours in a day. tc: The time of a working cycle (s), which is related to the degree of work busyness

Main specifications of types of cranes

Cranes have different main specifications depending on their type. For bridge cranes, the main specifications include lifting capacity, lifting height, span, lifting speed, trolley traveling speed, bridge traveling speed, working class, and load state level. Gantry cranes have similar specifications, but with crane traveling speed instead of bridge traveling speed. Jib cranes are characterized by lifting capacity, lifting height, arm length, lifting speed, slewing speed, working class, and load state level. It's important to note that these specifications can vary depending on the specific model and manufacturer of the crane.

Main specifications of bridge cranes

Crane Type | Usage Scenarios | Lifting Capacity Range | Span Range | Lift Height Range | Duty Cycle | Control Type | Environmental Factors |

Single Girder Overhead Travelling Crane | Manufacturing, Assembly, Maintenance | 1-20 tons | Up to 60 feet | Up to 30 feet | Light to Medium | Pendant, Radio Remote, or Cab | Indoor, Dry, and Non-corrosive |

Double Girder Overhead Crane | Steel Mills, Power Plants, Heavy Manufacturing | 5-100+ tons | Up to 150 feet | Up to 100 feet | Medium to Heavy | Pendant, Radio Remote, or Cab | Indoor or Outdoor, Dry, and Non-corrosive |

Jib Crane | Machining, Assembly Workstations | 0.5-5 tons | Up to 20 feet | Up to 20 feet | Light to Medium | Pendant or Cantilevered | Indoor, Dry, and Non-corrosive |

Underhung Crane | Low Headroom Applications | 1-10 tons | Up to 60 feet | Up to 30 feet | Light to Medium | Pendant or Radio Remote | Indoor, Dry, and Non-corrosive |

Grab Overhead Crane | Handling Loose Bulk Materials | 5-100+ tons | Up to 150 feet | Up to 100 feet | Medium to Heavy | Pendant, Radio Remote, or Cab | Indoor or Outdoor, Dry, and Non-corrosive |

Electromagnet Overhead Crane | Handling Ferrous Materials | 5-100+ tons | Up to 150 feet | Up to 100 feet | Medium to Heavy | Pendant, Radio Remote, or Cab | Indoor or Outdoor, Dry, and Non-corrosive |

Ladle Overhead Crane | Handling Molten Metal | 5-100+ tons | Up to 150 feet | Up to 100 feet | Medium to Heavy | Pendant, Radio Remote, or Cab | Indoor, High Temperature |

Explosion-proof Overhead Crane | Hazardous Environments | 1-100+ tons | Up to 150 feet | Up to 100 feet | Light to Heavy | Pendant, Radio Remote, or Cab | Indoor, Hazardous |

Clean Room Overhead Crane | Clean Room Environments | 1-20+ tons | Up to 60 feet | Up to 30 feet | Light to Medium | Pendant or Radio Remote | Indoor, Clean |

Automated Overhead Crane | Fully or Partially Automated Material Handling | 1-100+ tons | Up to 150 feet | Up to 100 feet | Light to Heavy | Automated Controls | Varies by Application |

Main specifications of types of gantry cranes

Type | Load Capacity | Span Width | Height Under | Usage Scenarios: |

Portable Gantry Crane | Up to 5 tons | Up to 30 feet | Up to 20 feet | Lifting small loads in warehousesMaintenance work in factories |

Adjustable Gantry Crane | Up to 15 tons | Up to 40 feet | Up to 35 feet | Heavy lifting in workshops Construction projects |

Fixed Gantry Crane | Up to 100 tons | Up to 150 feet | Up to 100 feet | Heavy-duty lifting operations in shipyardsLarge-scale construction projects |

Container Gantry Crane | Up to 100 tons | Up to 200 feet | Up to 100 feet | Loading and unloading of containers in ports and terminals |

Rail Mounted Gantry Crane (RMG) | Up to 120 tons | Up to 100 feet | Up to 80 feet | Container handling in intermodal rail yards and container terminals |

Small Lightweight Gantry Crane | Up to 2 tons | Up to 15 feet | Up to 10 feet | Lifting small loads in workshops and garages |

Mobile Gantry Crane | Up to 20 tons | Up to 40 feet | Up to 20 feet | Lifting and moving heavy loads in outdoor settings or large warehouses |

Main specifictions of types of jib cranes

Crane Type | Usage Scenarios | Lifting Capacity Range | Span Range | Lift Height Range | Duty Cycle | Control Type | Environmental Factors |

Jib Crane | Machining, Assembly Workstations | 0.5-5 tons | Up to 20 feet | Up to 20 feet | Light to Medium | Pendant or remote control | Indoor, Dry, and Non-corrosive |

Pillar jib crane | Indoor and outdoor use | 1-20 ton | 3~12m | 3~8 | Light to Medium | Pendant or remote control | Floor mounted with foundation or foudationless design |

Wall mounted jib crane | Workshop or workstation | 1-5 ton | 2-8m | 3-10m | light | Pendant or remote control | H steel column or concrete column of walls |

Wall travelling jib crane | Workshop or workstation | 1-3 ton | 5~12.5m | 6~30 | light | Pendant or remote control | Linked workshops |

Portable jib cranes | Workshop or workstation and outdoor use | 0.25t -2 ton | 2-6 m | 2-5m | Light | Pendant or remote control | General material handling conditions |

Hoisting and crane machinery terminology

1.1 Light lifting equipments

1.1.2 Rack-pinion jack - A jack that uses a rack as a rigid lifting device. 1.1.3 Hydraulic jack - A jack that uses a plunger or hydraulic cylinder as a rigid lifting device.

1.2 Pulley block - A small and light lifting device consisting of a fixed pulley group, a moving pulley group, and a lifting rope that passes successively over the fixed and moving pulleys.

1.3 Hoist - A small and light lifting device that is mounted on a common hanger and consists of a driving device, a transmission device, a braking device, and a flexible member for winding or clamping, or for lifting and lowering the lifting device.

1.3.1 Chain block - A hoist that is manually operated by pulling a chain and chain wheel to finally lift the lifting chain through a star wheel or nest chain wheel, thereby driving the lifting device to move up and down.

1.3.2 Lever block - A hoist that is manually operated by driving a wire rope or chain with a lever to move the lifting device.

1.3.2.1 Rope lever block - A hoist that is manually operated by driving a wire rope clip with a lever, alternately pulling the wire rope to drive the lifting device to move.

1.3.2.2 Chain lever block - A hoist that is manually operated by driving a nest chain wheel with a lever to wind and unwind the lifting chain, thereby driving the lifting device to move.

1.3.3 Electric hoist - A hoist that is driven by an electric motor and finally lifts the lifting rope or lifting chain through a drum, a star wheel, or a nest chain wheel, thereby driving the lifting device to move.

1.3.4 Pneumatic hoist - A hoist that is powered by compressed air.

1.4 Winch - A hoist that is driven by power through a flexible member to move the lifting device.

1.4.1 Drum hoist - A winch with the end of the lifting flexible member directly fixed on the drum, which has a dual function of winding and storing the lifting flexible member.

1.4.2 Friction hoist - A winch where the lifting flexible member only wraps around the drum for several turns, and when one end is wound up, the other end is released at the same time. The drum relies on the frictional force between the flexible member and the drum wall to create a tension difference between the entrance and exit ends of the flexible member, thereby providing traction force for the flexible member.

1.4.3 Capstan - A single drum frictional winch where the outer periphery of the drum is concave so that the lifted flexible member can slide automatically along the axis of the drum (capstan head) towards the bottom of the arc, without producing axial displacement.

1.5 Underslung monorail system - A light and small lifting device that consists of several simple lifting trolleys traveling along an overhead rail for transporting goods.

2.1 Classification of cranes according to their structure

2.1.1 Overhead type crane - A crane with a lifting device suspended from a hoist or a running trolley that runs along the overhead bridge.

2.1.1.1 Overhead travelling crane - A bridge-type crane supported directly on elevated tracks by running devices at both ends of the bridge.

2.1.1.2 Portal bridge crane (gantry crane) - A bridge-type crane with the bridge supported on the ground track or foundation by two side legs.

2.1.1.3 Semi-portal bridge crane - A bridge-type crane with one side of the bridge directly supported on elevated or high-rise building tracks and the other side supported on the ground track or foundation by legs.

2.1.2 Cable type crane - A crane with a lifting device suspended from a hoist that runs along a cable.

2.1.2.1 Cable crane - A cable-type crane with both ends of the supporting cable fixed to the top of two supports.

2.1.2.2 Portal cable crane - A cable-type crane with the end of the supporting cable fixed to both ends of the bridge, and the bridge supported on the ground track by two side legs.

2.1.3 Jib type crane - A crane with a lifting device suspended from the top of a jib or from a hoist that runs along the jib.

2.1.3.1 Portal slewing crane - A slewing jib-type crane with a portal frame that runs along the ground track and can be passed under by railway or other ground vehicles.

2.1.3.2 Semi-portal slewing crane - A slewing jib-type crane with one side of the semi-portal frame supported on elevated tracks by a running truck and the other side supported on the ground track or foundation by legs and a running truck.

2.1.3.3 Tower crane - A slewing jib-type crane with the jib mounted on the top of a vertical tower.

2.1.3.4 Railway crane - A jib-type crane that operates on railway lines and is used for loading and unloading and for rescuing railway locomotives, vehicles, and overturned trains.

2.1.3.5 Mobile crane - A jib-type crane that can be equipped with columns or towers and can run on an untracked surface with or without a load, relying on its own weight to maintain stability.

2.1.3.6 Floating crane - A jib-type crane supported and operated by a special floating ship, which floats on the waterway and can sail or be towed along the waterway.

2.1.3.7 Deck crane - A slewing jib-type crane mounted on a ship's deck for loading and unloading cargo.

2.1.3.8 Derrick crane - A slewing jib-type crane with its lower end hinged to the lower part of a mast, its upper end connected to the masthead by a wire rope, and the mast itself kept upright by top and bottom supports.

2.1.3.9 Cantilever crane - A jib-type crane with a lifting device suspended from the end of a cantilever or from a hoist that runs along the cantilever.

2.1.3.9.1 Pillar jib crane - A cantilever crane with a cantilever that rotates around a fixed pillar on a base, or where the cantilever is rigidly connected to the turning pillar, rotating together relative to the vertical centerline in the support base composed of pillars and cantilevers.

2.1.3.9.2 Wall crane - A cantilever crane mounted on a wall or column that cannot be inclined.

2.2 Cranes are classified by pick-up device and use

2.2.1 Hook crane / Hook crane - a crane that uses a hook as a retrieval device

2.2.2 Grabbing crane / Grabbing crane - a crane with a grab bucket as a pick-up device

2.2.3 Electromagnetic Crane / Magnet crane - a crane with an electromagnetic suction cup as a pick-up device

2.2.4 Metallurgy crane/ (see GB6974.16) Metallurgy crane - a special crane that adapts to the special requirements of metal smelting, rolling and other thermal processing, and is directly used in the production process

2.2.5 Stacking crane/ (see GB6974.17) Stacking crane - a crane that usually uses a fork as a pick-up device to stack items in a warehouse or workshop

2.2.6 Container cranes/ (see GB6974.19) Container cranes - cranes for loading and unloading container ships and vehicles, stacking and destacking or transshipment of containers at port terminals and station freight yards

2.2.7 Erection crane / Erection crane - a crane for placing prefabricated parts, lifting machinery and equipment, etc.

2.2.8 Rescue crane / Salvage crane - a crane used for emergency rescue and cleaning up the accident scene

2.3 Cranes are classified according to their transportation methods

2.3.1 Fixed base crane - a crane that is fixed to a foundation or support base and can only work in situ

2.3.2 Traveling crane - a rail or trackless crane that can be moved as a whole

2.3.2.1 Self-propelled crane / Self-propelled crane - during operation or transportation, the whole machine can run along the track or trackless by relying on its own operating mechanism

2.3.2.2 Trailer crane / Trailer crane - a running crane that does not have running power itself and is towed by a tractor (tractor, etc.)

2.3.3 Climbing crane / Climbing crane - a crane that is installed on the building components under construction and can continue to climb upwards by its own mechanism as a whole as the building increases

2.3.4 Portable crane / Portable crane - a crane mounted on a base that can be moved from one site to another by manpower or with the aid of auxiliary equipment

2.3.5 Lorry crane / Lorry crane - a crane that is fixed to a truck and is usually used for loading and unloading goods on the truck

2.3.6 Radial crane / Radial crane - a crane that can move along an arc track around a fixed vertical center line

2.4 Cranes are classified according to the driving mode of the working mechanism

2.4.1 Manual crane / Manual crane - a crane driven by human power

2.4.2 Electric crane / Electric crane - a crane driven by electricity

2.4.3 Hydraulic crane / Hydraulic crane - a crane driven by hydraulic or hydraulic power

2.4.4 Internal combustion crane / Diesel crane - a crane driven by an internal combustion engine (diesel engine, gasoline engine)

2.4.5 Steam crane / Steam crane - a crane driven by a steam engine

2.5 Cranes are classified by slewing capacity

2.5.1 Slewing Crane / Slewing Crane - A crane in which the superstructure (on board), or slewing platform, can carry a hoisted load around an axis of rotation, relative to the substructure (on board), or base

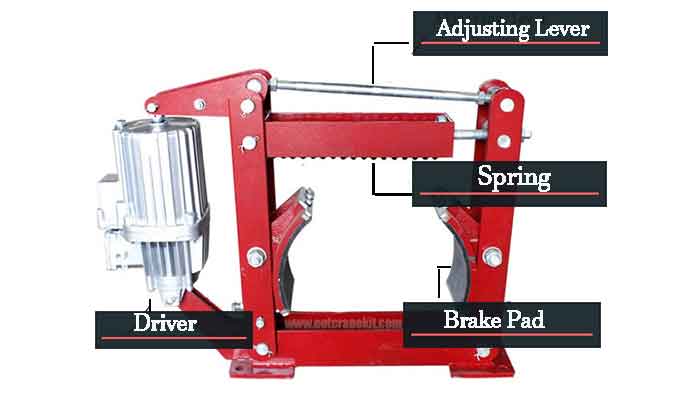

2.5.1.1 Full-circle slewing crane / Full-circle slewing crane - a slewing crane in which the upper structure (on the vehicle) or the slewing platform can rotate relative to the lower structure (off the vehicle) or the base within a range of more than 360°