5 Ton Gantry Crane Comprehensive Guide: Right 5 Ton Crane for You

5 ton gantry crane for sale. A guide on 5 ton gantry cranes, all types of 5 ton gantry crane designs, uses & selection. Get your 5 ton gantry crane design.

Category: 5 Ton Gantry Crane

Your Trusted Gantry Crane Manufacturer & Supplier

5 Ton Gantry Crane Comprehensive Guide: Right 5 Ton Crane for You

5 ton gantry crane for sale. A guide on 5 ton gantry cranes, all types of 5 ton gantry crane designs, uses & selection. Get your 5 ton gantry crane design.

A 5 ton gantry crane is a type of industrial lifting equipment designed to move and position heavy loads weighing up to 5 tons. Gantry cranes are characterized by their overhead horizontal beam (bridge) supported by legs on either side, which can move along a runway or track. These cranes are widely used in various industries, including manufacturing, construction, shipping, and warehousing, where precise and controlled lifting and material handling are required.

Here is an overview of key aspects related to 5 ton gantry cranes:

- Load Capacity: As the name suggests, a 5 ton gantry crane can lift and move loads weighing up to 5 tons. This capacity makes it suitable for a wide range of applications where moderate to heavy lifting is necessary.

- Mobility: Gantry cranes are mobile and can be positioned where needed. They come in two main types:

Portable Gantry Crane: These cranes are designed for easy transport and can be set up quickly at different locations. They are ideal for applications that require flexibility and versatility.

Fixed Gantry Crane: These cranes are installed in a fixed location and are often used in more permanent industrial setups. - Span: The span refers to the distance between the legs of the gantry crane. The span can vary depending on the specific requirements of the application.

- Control Systems: 5 ton gantry cranes are equipped with advanced control systems that allow for precise and safe load handling. These systems can include features like variable speed control, load monitoring, and safety mechanisms to prevent accidents.

- Materials: Gantry cranes can be constructed from different materials, with steel and aluminum being common choices. The choice of material depends on factors such as load capacity, corrosion resistance, and mobility requirements.

- Applications: 5 ton gantry cranes are used in a wide range of industries and applications, including:

- Manufacturing: for lifting and moving heavy machinery and components.

Construction: for positioning materials and equipment at construction sites.

Warehousing: for efficient storage and retrieval of heavy items.

Shipping and logistics: for loading and unloading cargo containers.

Automotive: for handling vehicle components during assembly. - Safety: Safety is a paramount concern in gantry crane operation. These cranes are equipped with safety features such as overload protection, emergency stop buttons, and limit switches to prevent accidents and protect personnel.

In summary, a 5 ton gantry crane is a versatile and essential piece of equipment in industries that require efficient and precise material handling. Its ability to lift heavy loads with precision, coupled with mobility and safety features, makes it a valuable asset for a wide range of applications.

In this comprehensive guide, we will navigate the intricate technical landscape of 5 ton gantry cranes, exploring their components, operation, and applications from an engineering perspective.

A Comprehensive Engineering Overview of 5 Ton Gantry Cranes

Before we embark on this journey through the world of engineering excellence, let's take a moment to understand why 5 ton gantry cranes are so significant in the field. These cranes represent the pinnacle of engineering innovation in lifting equipment. They are meticulously engineered to achieve the perfect balance between power, precision, and safety.

At their core, 5 ton gantry cranes are mechanical marvels that rely on complex systems of components, controls, and electronics to lift heavy loads with precision and efficiency. They are more than just machines; they are the embodiment of human ingenuity, a testament to our ability to conquer the most demanding tasks in the industrial and construction sectors.

As we delve into the engineering intricacies of 5 ton gantry cranes, we will explore the components that make them tick, the precise engineering behind their operation, and their diverse applications in various industries. Whether you're an engineer seeking to optimize crane performance, an operator ensuring safety, or a decision-maker evaluating equipment for your business, this guide is your comprehensive resource for understanding the engineering excellence that drives 5 ton gantry cranes.

Join us as we deconstruct these mechanical marvels, unravel their engineering secrets, and appreciate the vital role they play in the world of heavy lifting and material handling. Let's embark on this journey together, and by the end, you'll have a newfound appreciation for the significance of 5 ton gantry cranes in the engineering world.

Types of 5 ton gantry cranes for sale

5 ton gantry cranes can also be classified based on various aspects related to girder design, girder numbers, lifting systems, leg girders, and traveling types. Here's a classification of 5 ton gantry cranes based on these criteria:

Based on Girder Design:

- Single Girder Gantry Crane (5 ton): Features a single horizontal girder for load support. Suitable for moderate-load applications and where simplicity is essential.

- Double Girder Gantry Crane (5 ton): Equipped with two horizontal girders for added load capacity and stability. Ideal for heavy-duty lifting tasks."

Single Girder Gantry Crane (5 ton):

Features a single horizontal girder for load support.

Suitable for moderate-load applications and where simplicity is essential.

Advantages of 5 ton Single Girder Gantry Crane:

Cost-effective: Lower initial cost compared to double girder cranes.

Easy installation and maintenance: Simpler design results in easier maintenance procedures.

Suitable for moderate loads: Ideal for tasks with 5 ton lifting requirements.

Typical Applications of 5 ton Single Girder Gantry Crane:

Manufacturing facilities: Handling materials during production processes.

Workshops: Assisting in equipment assembly and maintenance.

Warehouses: Loading and unloading goods.

Typical Loads or Objects Handling with 5 ton Single Girder Gantry Crane:

Steel beams and structures

Heavy machinery components

Palletized goods

Automotive parts

Double Girder Gantry Crane (5 ton):

Equipped with two horizontal girders for added load capacity and stability.

Ideal for heavy-duty lifting tasks.

Advantages of 5 ton Double Girder Gantry Crane:

High load capacity: Suited for lifting and transporting heavier loads.

Enhanced stability: Dual girders provide increased stability and precision.

Longer span: Suitable for covering a wider area.

Typical Applications of 5 ton Double Girder Gantry Crane:

Steel fabrication: Handling and positioning heavy steel materials.

Shipbuilding: Assembling and moving ship components.

Material yards: Efficiently managing materials and products.

Typical Loads or Objects Handling with 5 ton Double Girder Gantry Crane:

Large steel coils

Ship sections

Bulk materials

Industrial machinery

Overview of 5 ton gantry cranes based on the girder design, specifically Box Girder Gantry Cranes and Truss Girder Gantry Cranes:

Box Girder Gantry Crane (5 ton):

Features a box-shaped horizontal girder for load support, which provides increased strength and rigidity.

Suitable for applications requiring high load capacity and precision.

Advantages of 5 ton Box Girder Gantry Crane:

High load capacity: The box girder design enhances the crane's ability to handle heavy loads.

Enhanced stability: Provides increased rigidity and resistance to torsional forces.

Suitable for longer spans: Ideal for applications that require covering a wide area.

Typical Applications of 5 ton Box Girder Gantry Crane:

Heavy machinery manufacturing: Lifting and positioning large machinery components.

Shipbuilding: Assembling and moving ship sections and components.

Material yards: Efficiently managing heavy materials and products.

Typical Loads or Objects Handling with 5 ton Box Girder Gantry Crane:

Large industrial equipment

Heavy steel structures

Bulk materials

Truss Girder Gantry Crane (5 ton):

Features a truss-shaped horizontal girder for load support, offering exceptional strength and stability.

Commonly used in demanding environments where heavy lifting is required.

Advantages of 5 ton Truss Girder Gantry Crane:

Exceptional strength: The truss girder design provides high load-carrying capacity.

Durability: Well-suited for rugged environments and challenging conditions.

Versatile: Can handle various loads, making it suitable for diverse applications.

Typical Applications of 5 ton Truss Girder Gantry Crane:

Construction sites: Lifting heavy construction materials and components.

Mining operations: Handling large quantities of ore and materials.

Steel mills: Moving and positioning heavy steel products.

Typical Loads or Objects Handling with 5 ton Truss Girder Gantry Crane:

Mining equipment

Steel coils and sheets

Oversized construction materials

Engineering Face-off: 5 Ton Overhead Crane vs. 5 Ton Gantry Crane

As for heavy lifting and material handling, choosing the right crane is a critical engineering decision. Two prominent contenders for this purpose are the 5 ton overhead crane and the 5 ton gantry crane. This section is dedicated to a technical comparison between these two crane types. We'll explore the engineering nuances that differentiate them and examine scenarios where the engineering excellence of 5 ton gantry cranes often emerges as the preferred choice.

Engineering Decision-Making: A Technical Comparison of Overhead and Gantry Cranes

Load Capacity and Span

When engineers are tasked with selecting a crane, one of the primary considerations is load capacity. Both 5 ton overhead cranes and 5 ton gantry cranes are engineered to handle substantial weights, but they have differences in their span capabilities. Overhead cranes are typically designed for larger spans, making them suitable for covering vast areas within a facility. Gantry cranes, on the other hand, excel in applications where precise positioning and mobility are essential, and they are often used in smaller workspaces.

Installation and Infrastructure

Engineers must assess the existing infrastructure and workspace when choosing between these crane types. Overhead cranes require robust overhead structures or runways for installation. This can be a significant engineering consideration, especially in facilities where these structures need to be constructed or modified. Gantry cranes, however, offer more flexibility as they do not rely on overhead support. Their mobility and ability to be set up quickly make them advantageous in various industrial settings.

Mobility and Versatility

Gantry cranes are known for their mobility and versatility. Engineers value their ability to move loads horizontally and vertically with precision, making them ideal for tasks that demand flexibility and adaptability. Overhead cranes, while excellent for lifting heavy loads in a fixed area, lack the same level of mobility and versatility.

Differences:

Mounting Location:

Overhead Crane: Mounted on an overhead structure or runway attached to the building's ceiling.

Gantry Crane: Supported by legs on the ground and doesn't require an overhead structure.

Mobility:

Overhead Crane: Fixed in position, typically moving along a fixed path on the runway.

Gantry Crane: Mobile and can be moved to different locations within a facility.

Span:

Overhead Crane: Suitable for larger spans, covering a wide area.

Gantry Crane: Suited for smaller spans and is ideal for precise positioning.

Differences:

Installation:

Overhead Crane: Requires a robust overhead support structure, potentially involving construction or modification.

Gantry Crane: Easier to install as it does not rely on an overhead structure, resulting in quicker setup.

Versatility:

Overhead Crane: Offers limited versatility in terms of mobility and adaptability.

Gantry Crane: Highly versatile, capable of adapting to changing operational needs and locations.

Cost:

Overhead Crane: Typically involves higher initial installation costs due to the need for overhead support structures.

Gantry Crane: Often more cost-effective both in terms of initial investment and long-term operation.

Similarities:

Load Capacity:

Both 5 ton overhead cranes and 5 ton gantry cranes can lift and move loads weighing up to 5 tons.

Applications:

Both types of cranes are used in various industrial applications for lifting and material handling tasks.

Control Systems:

Both types are equipped with advanced control systems for precise load handling and safety.

Safety:

Safety is a paramount concern for both types, and they are equipped with safety features such as overload protection and emergency stops.

Now, let's represent this information in a table format for a clear visual comparison:

| Aspect | 5 Ton Overhead Crane | 5 Ton Gantry Crane |

|---|---|---|

| Mounting Location | Attached to ceiling | Ground-supported |

| Mobility | Fixed | Mobile |

| Span | Larger spans | Smaller spans |

| Installation | Requires overhead support structures | Easier and quicker setup |

| Versatility | Limited | Highly versatile |

| Cost | Higher initial installation costs | More cost-effective |

| Load Capacity | Up to 5 tons | Up to 5 tons |

| Applications | Various industrial applications | Various industrial applications |

| Control Systems | Advanced control systems | Advanced control systems |

| Safety Features | Overload protection, emergency stops, etc. | Overload protection, emergency stops, etc. |

This table provides a concise and structured overview of the key differences and similarities between 5 ton overhead cranes and 5 ton gantry cranes, aiding in better understanding their engineering characteristics.

Engineering Excellence: When 5 Ton Gantry Cranes Win the Day

Versatility

One of the standout features of 5 ton gantry cranes is their versatility. Their ability to be easily transported, set up, and adjusted to different locations within a facility makes them indispensable in industries where workflows change frequently. This engineering excellence ensures that gantry cranes can adapt to evolving operational needs.

Ease of Installation

From an engineering standpoint, the installation of gantry cranes is often more straightforward compared to overhead cranes. Engineers appreciate the reduced complexity and time required for setup. This not only leads to cost savings but also minimizes operational disruptions during installation.

Cost-Effectiveness

Gantry cranes are typically more cost-effective in terms of both initial investment and long-term operation. Their ease of installation and mobility contribute to lower engineering and construction costs. Additionally, their adaptability can lead to increased productivity and cost savings over time.

In many engineering scenarios, the versatility, mobility, and cost-effectiveness of 5 ton gantry cranes tip the scales in their favor. While both 5 ton overhead cranes and 5 ton gantry cranes have their engineering strengths, the latter often emerges as the preferred choice in applications that require precise positioning, adaptability, and cost-conscious engineering solutions.

Based on Lifting System: Wire Rope Hoist & Electric Chain Hoist Gantry Crane

- Wire Rope Hoist Gantry Crane (5 ton): Uses a wire rope hoist as the primary lifting mechanism, suitable for precise and controlled lifting.

- Electric Chain Hoist Gantry Crane (5 ton): Utilizes an electric chain hoist for lifting and lowering loads efficiently.

- Magnet Gantry Crane (5 ton): Equipped with a magnet attachment for lifting ferrous materials, commonly used in metalworking and recycling industries.

Wire Rope Hoist Gantry Crane (5 ton):

Utilizes a wire rope hoist as the primary lifting mechanism.

Suitable for precise and controlled lifting operations.

Commonly used in various industries for its ability to handle loads with accuracy.

Advantages of 5 ton Wire Rope Hoist Gantry Crane:

Precise load control: Offers precise and controlled lifting and lowering of loads.

Versatility: Suitable for various applications and industries.

Durable: Wire rope hoists are known for their longevity and reliability.

Typical Applications of 5 ton Wire Rope Hoist Gantry Crane:

Manufacturing: Handling machinery components and heavy materials.

Construction: Lifting and positioning structural elements.

Warehousing: Efficiently moving and stacking goods.

Typical Loads or Objects Handling with 5 ton Wire Rope Hoist Gantry Crane:

Machinery parts

Steel plates and beams

Industrial equipment

Electric Chain Hoist Gantry Crane (5 ton):

Utilizes an electric chain hoist as the primary lifting mechanism.

Known for its efficiency in lifting and lowering loads.

Offers a balance between reliability and cost-effectiveness.

Advantages of 5 ton Electric Chain Hoist Gantry Crane:

Efficient lifting: Provides efficient and reliable load handling.

Lower maintenance: Chain hoists require minimal maintenance.

Suitable for various industries: Used in manufacturing, logistics, and more.

Typical Applications of 5 ton Electric Chain Hoist Gantry Crane:

Assembly lines: Assisting in product assembly processes.

Warehouses and distribution centers: Efficient material handling.

Auto repair shops: Lifting vehicle components and engines.

Typical Loads or Objects Handling with 5 ton Electric Chain Hoist Gantry Crane:

Automotive parts

Consumer goods

Heavy tools and equipment

Equipped with a magnet attachment for lifting ferrous materials.

Commonly used in metalworking and recycling industries.

Ideal for handling materials like scrap metal, steel, and other magnetic items.

Advantages of 5 ton Magnet Gantry Crane:

Efficient metal handling: Speeds up the process of collecting and transporting ferrous materials.

Cost-effective: Reduces manual labor and increases productivity.

Eco-friendly: Facilitates recycling efforts in metalworking and waste management.

Typical Applications of 5 ton Magnet Gantry Crane:

Scrap metal yards: Handling and sorting scrap metal.

Metal fabrication: Moving and positioning metal sheets and components.

Recycling facilities: Assisting in the recycling process.

Typical Loads or Objects Handling with 5 ton Magnet Gantry Crane:

Scrap metal

Steel sheets and plates

Magnetic materials

These lifting system classifications provide insight into the specific capabilities and applications of 5 ton gantry cranes equipped with wire rope hoists, electric chain hoists, and magnet attachments. Each type caters to distinct industries and materials handling needs.

Based on Gantry Leg Design: A-frame, L Leg & U Leg Gantry Cranes

Design: Features an A-shaped frame structure with two vertical legs supporting the horizontal girder.

Advantages: Provides stability and is commonly used in workshops and small yards where space is limited.

Typical Applications: Used in manufacturing, workshops, and smaller storage yards for light to moderate load handling.

Typical Loads or Objects Handling: Machinery components, palletized goods, automotive parts.

Design: The crane has legs that resemble the shape of the letter "L," with one horizontal leg and one vertical leg.

Advantages: Offers stability and can be customized for specific height and span requirements.

Typical Applications: Commonly used in manufacturing and material handling facilities where load precision and space optimization are crucial.

Typical Loads or Objects Handling: Steel structures, equipment, machinery parts.

Design: Features a U-shaped frame structure with two vertical legs and a horizontal girder connecting them.

Advantages: Provides a clear space between the legs for efficient load placement and removal.

Typical Applications: Ideal for handling large and bulky materials in settings like warehouses, construction sites, and material yards.

Typical Loads or Objects Handling: Large construction materials, industrial equipment, oversized products.

Each type of leg girder design offers unique advantages and is suitable for different operational settings and load requirements. When choosing the right 5 ton gantry crane, it's essential to consider factors such as available space, load capacity, and the nature of the materials or objects being handled to ensure optimal performance and efficiency.

Based on Traveling Types: Stationery Gantry, Rail Travelling & Wheeled Gantry Cranes

- Stationary Gantry Crane (5 ton): Remains fixed in one location and doesn't have the ability to move. Often used in workshops for specific tasks.

- Rail-Mounted Gantry Crane (RMG) (5 ton): Designed to run on rails for precise and efficient load handling. Commonly used in industries with high throughput, such as container terminals.

- Rubber-Tired Gantry Crane (RTG) (5 ton): Mobile gantry crane with rubber tires for flexibility in moving and positioning loads, often used in container yards and ports.

- Adjustable Height Gantry Crane (5 ton): Designed with an adjustable height feature that allows for vertical movement, accommodating various load sizes and heights.

- . Portable Gantry Crane (5 ton): Equipped with wheels or casters, allowing for easy mobility within a workspace. Commonly used for maintenance and repair work.

Stationary Gantry Crane (5 ton):

Remains fixed in one location and doesn't have the ability to move.

Often used in workshops and industrial settings for specific tasks where loads need to be lifted and positioned at a single location.

Advantages of 5 ton Stationary Gantry Crane:

Stability: Provides a stable and fixed lifting point.

Simple operation: Well-suited for repetitive tasks with fixed loads.

Cost-effective: Lower initial investment compared to mobile options.

Typical Applications of 5 ton Stationary Gantry Crane:

Production lines: Assisting in manufacturing and assembly processes.

Workshops: Handling equipment and materials within a defined workspace.

Warehouses: Lifting and positioning goods in a designated area.

Typical Loads or Objects Handling with 5 ton Stationary Gantry Crane:

Machine parts

Raw materials

Palletized products

Rail-Mounted Gantry Crane (RMG) :

Designed to run on rails for precise and efficient load handling.

Commonly used in industries with high throughput, such as container terminals and intermodal facilities.

Advantages of 5 ton Rail-Mounted Gantry Crane (RMG):

Precision and efficiency: Controlled movement along rails for precise load positioning.

High throughput: Suited for handling large volumes of containers and goods.

Space optimization: Maximizes storage and handling space in container yards.

Typical Applications of 5 ton Rail-Mounted Gantry Crane (RMG):

Container terminals: Stacking and moving shipping containers.

Intermodal facilities: Efficiently handling cargo containers and goods in transit.

Port operations: Ensuring smooth and organized container management.

Typical Loads or Objects Handling with 5 ton Rail-Mounted Gantry Crane (RMG):

Shipping containers

Bulk cargo

Intermodal containers

Rubber-Tired Gantry Crane (RTG) (5 ton):

Mobile gantry crane with rubber tires for flexibility in moving and positioning loads.

Often used in container yards, ports, and logistics facilities.

Advantages of 5 ton Rubber-Tired Gantry Crane (RTG):

Mobility: Ability to move and position containers or loads within the yard.

Flexibility: Handling containers and goods in dynamic environments.

Reduced infrastructure requirements: No need for fixed tracks or rails.

Typical Applications of 5 ton Rubber-Tired Gantry Crane (RTG):

Container yards: Stacking and organizing shipping containers.

Port terminals: Efficiently managing container movements in and out of ships.

Logistics centers: Handling various types of cargo and goods.

Typical Loads or Objects Handling with 5 ton Rubber-Tired Gantry Crane (RTG):

Shipping containers

Bulk cargo

Heavy machinery

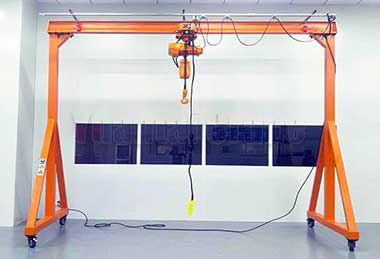

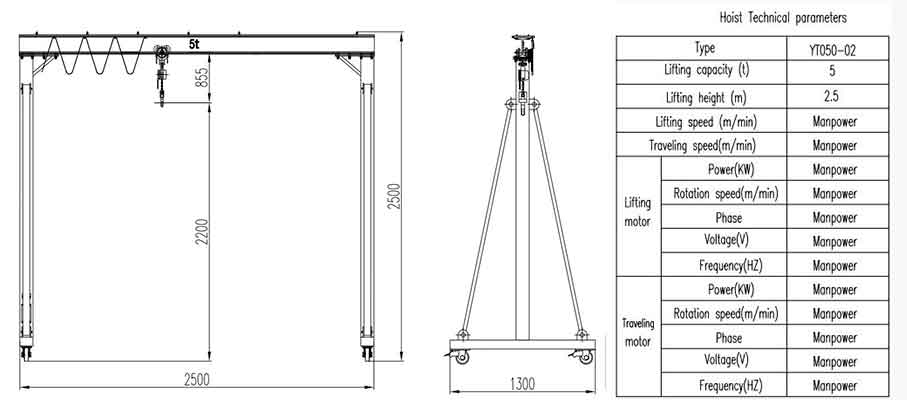

Portable Gantry Crane (5 ton):

Equipped with wheels or casters, allowing for easy mobility within a workspace.

Designed for applications where the crane needs to be moved to different locations within the same facility.

Advantages of 5 ton Portable Gantry Crane:

Mobility: Can be relocated to different areas as needed.

Versatility: Suitable for various tasks within a facility.

Easy setup: Quick installation and no need for a fixed structure.

Typical Applications of 5 ton Portable Gantry Crane:

Maintenance and repair work: Lifting and servicing equipment in different parts of a facility.

Temporary job sites: Handling loads in locations where a permanent crane isn't feasible.

Workshops with changing requirements: Adapting to different lifting needs.

Typical Loads or Objects Handling with 5 ton Portable Gantry Crane:

Machine components

Construction materials

Equipment maintenance

Adjustable Height Gantry Crane (5 ton):

Designed with an adjustable height feature that allows for vertical movement, accommodating various load sizes and heights.

Provides flexibility in adapting to different lifting needs.

Advantages of 5 ton Adjustable Height Gantry Crane:

Versatility: Can handle loads of varying sizes and heights.

Precision positioning: Allows for precise vertical movement.

Space optimization: Accommodates different lifting requirements within the same workspace.

Typical Applications of 5 ton Adjustable Height Gantry Crane:

Maintenance tasks: Lifting and servicing equipment with varying heights.

Workshops with diverse needs: Adapting to different load sizes and configurations.

Warehouses with changing storage requirements: Adjusting to stack and retrieve goods of varying heights.

Typical Loads or Objects Handling with 5 ton Adjustable Height Gantry Crane:

Machinery components

Large industrial equipment

Variable-sized palletized goods

These classifications of 5 ton gantry cranes based on traveling types provide insights into their mobility, adaptability, and suitability for various industries and tasks. The choice of traveling type depends on the specific operational requirements and workspace configurations.

On Gantry Crane Materials : Steel Gantry Cranes and Aluminum Gantry Cranes:

Constructed primarily from steel materials, including the main frame, girders, and support structures.

Designed for durability, strength, and the ability to handle heavy loads.

Advantages of 5 ton Steel Gantry Crane:

High load capacity: Designed to handle substantial weight and heavy materials.

Durability: Resistant to wear and tear, making it suitable for rugged environments.

Stability: Offers excellent stability and rigidity during lifting operations.

Typical Applications of 5 ton Steel Gantry Crane:

Heavy machinery manufacturing: Lifting and positioning large machine components.

Steel fabrication: Handling steel structures, beams, and plates.

Construction sites: Assisting in lifting and assembly tasks.

Typical Loads or Objects Handling with 5 ton Steel Gantry Crane:

Large industrial machinery

Steel sheets and beams

Construction materials

Aluminum Gantry Crane (5 ton):

Constructed primarily from aluminum materials, including the main frame and girders.

Designed for applications where weight is a critical factor, such as portability and reduced structural load.

Advantages of 5 ton Aluminum Gantry Crane:

Lightweight: Easier to move and transport compared to steel gantry cranes.

Corrosion-resistant: Suitable for outdoor and marine environments due to its resistance to rust.

Portability: Ideal for applications where frequent setup and relocation are necessary.

Typical Applications of 5 ton Aluminum Gantry Crane:

Aerospace industry: Handling aircraft components and parts.

Marine environments: Lifting and positioning boat and ship components.

Cleanroom environments: Utilized in industries with stringent cleanliness requirements.

Typical Loads or Objects Handling with 5 ton Aluminum Gantry Crane:

Aircraft components

Marine equipment

Precision instruments

Both steel and aluminum gantry cranes have their unique advantages and are suitable for different applications. The choice between them depends on factors such as load capacity, environmental conditions, mobility requirements, and the specific needs of the industry or task at hand.

Aluminum vs. Steel A-Frame: A Technical Deep Dive into 5 Ton Gantry Crane Materials

The materials used in the construction of 5 ton gantry cranes play a pivotal role in their engineering and performance. This deep dive into materials specifically focuses on aluminum and A-frame variants, shedding light on the engineering intricacies behind these choices.

Aluminum 5 ton gantry cranes are engineered for lightweight yet robust performance. They excel in environments where corrosion resistance is crucial, and their engineering brilliance lies in their ability to provide durability without compromising on weight.

The steel A-frame 5 ton gantry cranes, on the other hand, showcase a different facet of engineering. Their sturdy steel construction makes them ideal for heavy-duty applications, offering unmatched strength and stability. Engineers will appreciate the weight-bearing capabilities and engineering considerations involved in their design.

let's compare the similarities and differences between steel gantry cranes and aluminum gantry cranes, each with a 5 ton capacity, in both bullet point and table formats:

Similarities:

- Load Capacity: Both steel and aluminum gantry cranes with a 5 ton capacity can lift and move loads weighing up to 5 tons.

- Mobility: Both types of gantry cranes are mobile and can be positioned where needed within a facility.

- Applications: Steel and aluminum gantry cranes are used in various industrial applications for lifting and material handling tasks.

- Control Systems: Both types are equipped with advanced control systems for precise load handling and safety.

- Safety Features: Safety is a paramount concern for both steel and aluminum gantry cranes, and they are equipped with safety features such as overload protection and emergency stops.

Differences:

Material:

Steel Gantry Crane: Constructed from steel, which provides robustness and durability, suitable for heavy-duty applications.

Aluminum Gantry Crane: Constructed from aluminum, which is lightweight and corrosion-resistant, making it ideal for environments where rust is a concern.

Weight:

Steel Gantry Crane: Heavier due to the density of steel, which affects transportation and ease of setup.

Aluminum Gantry Crane: Lightweight, making it easier to transport and set up, particularly in locations with weight restrictions.

Corrosion Resistance:

Steel Gantry Crane: Requires additional corrosion protection measures to prevent rust, especially in corrosive environments.

Aluminum Gantry Crane: Naturally corrosion-resistant, suitable for outdoor use and environments with moisture or chemicals.

Strength:

Steel Gantry Crane: Known for its high strength, making it suitable for heavy and demanding lifting tasks.

Aluminum Gantry Crane: Not as strong as steel but still capable of handling moderate to heavy loads efficiently.

Cost:

Steel Gantry Crane: Generally more affordable upfront, but long-term maintenance costs can be higher due to rust prevention.

Aluminum Gantry Crane: Typically more expensive initially, but lower long-term maintenance costs due to corrosion resistance.

Now, let's represent this information in a table format for a clear visual comparison:

| Aspect | Steel Gantry Crane | Aluminum Gantry Crane |

|---|---|---|

| Load Capacity | Up to 5 tons | Up to 5 tons |

| Mobility | Mobile and positionable | Mobile and positionable |

| Applications | Various industrial applications | Various industrial applications |

| Control Systems | Advanced control systems | Advanced control systems |

| Safety Features | Overload protection, emergency stops, etc. | Overload protection, emergency stops, etc. |

| Material | Steel | Aluminum |

| Weight | Heavier | Lightweight |

| Corrosion Resistance | Requires corrosion protection | Naturally corrosion-resistant |

| Strength | High strength | Moderate strength |

| Cost | Generally more affordable upfront, but higher long-term maintenance costs | Typically more expensive initially, but lower long-term maintenance costs |

This table provides a structured overview of the similarities and differences between steel and aluminum gantry cranes with a 5 ton capacity, helping users make informed decisions based on specific operational and environmental requirements.

Advanced Engineering Features and Benefits of 5 Ton Gantry Cranes

As our exploration of 5 ton gantry cranes continues, we venture into the realm of advanced engineering features and the remarkable benefits they offer. In this section, we will uncover the inner workings of these machines from an engineering perspective, revealing the secrets behind their efficiency. Additionally, we will delve into the economic aspect, exploring how engineering excellence in 5 ton gantry cranes translates into cost-efficiency and substantial benefits.

Engineering Efficiency: Unveiling the Inner Workings of 5 Ton Gantry Cranes

Efficiency is the cornerstone of every engineering marvel, and 5 ton gantry cranes are no exception. These machines are a symphony of precise engineering, designed to optimize workspace efficiency and reduce downtime to a minimum. In this part, we will pull back the curtain and reveal the inner workings of 5 ton gantry cranes.

One key engineering aspect to explore is the precision control systems. Engineers have meticulously designed these systems to ensure that the crane moves and lifts loads with unparalleled accuracy. This precision is crucial in industries where even the slightest deviation can lead to costly errors.

Customizability is another engineering marvel. 5 ton gantry cranes can often be tailored to suit specific requirements, further enhancing their efficiency. Engineers play a vital role in configuring these cranes to meet the exact needs of various industries and applications.

Calculating Cost-Efficiency: Engineering Benefits of 5 Ton Gantry Cranes

Cost-efficiency is a critical consideration in any engineering endeavor. In this part, we will explore how the engineering benefits of 5 ton gantry cranes translate into substantial savings over time. Engineers and decision-makers will discover the long-term advantages that these cranes offer, making them an intelligent investment.

Reduced labor costs are a notable engineering benefit. 5 ton gantry cranes can handle heavy loads with minimal manpower, freeing up human resources for other tasks. Increased productivity is another aspect; these cranes are engineered to expedite operations, resulting in higher output and efficiency.

Maintenance is a key engineering consideration. By designing 5 ton gantry cranes for easy maintenance, engineers ensure that downtime is minimized. This translates into fewer maintenance hours and reduced costs over the crane's lifespan.

As we journey deeper into the engineering aspects of 5 ton gantry cranes, we unveil the secrets behind their efficiency and the economic advantages they offer. Engineers and industry professionals will gain a profound appreciation for the meticulous engineering that goes into these machines, making them not only powerful lifting tools but also smart business investments. Join us as we continue to explore the advanced engineering features and benefits that set 5 ton gantry cranes apart.

Precision Engineering in Industrial Applications of 5 Ton Gantry Cranes

In this section of our engineering journey through 5 ton gantry cranes, we immerse ourselves in the world of industrial applications. We will explore how engineering excellence in 5 ton gantry cranes revolutionizes operations across various industries. Additionally, we'll delve into real-world applications, providing insights into how these cranes are deployed to address unique engineering challenges.

5 ton gantry cranes are versatile lifting equipment used across various industrial applications due to their ability to handle moderate to heavy loads with precision and mobility. Here are some typical industrial applications, types, functions, and application environments for 5 ton gantry cranes:

Typical Industrial Applications:

- Manufacturing: Gantry cranes are widely used in manufacturing facilities for tasks such as moving heavy machinery, positioning components on assembly lines, and handling raw materials.

- Construction: These cranes are utilized on construction sites to lift and position building materials, equipment, and structures.

- Warehousing and Logistics: Gantry cranes are employed in warehouses and distribution centers for efficient loading and unloading of goods, as well as for stacking and organizing inventory.

- Shipbuilding and Ports: They are used in shipyards for lifting ship components and in ports for container handling and cargo placement.

- Automotive Industry: Gantry cranes are essential for handling vehicle components during assembly and manufacturing processes.

- Aerospace: These cranes play a crucial role in aerospace manufacturing, supporting the assembly and maintenance of aircraft.

- Mining and Heavy Industry: In mining and heavy industries, 5 ton gantry cranes are used for moving raw materials, machinery, and equipment.

Typical Types of 5 Ton Gantry Cranes:

- Single Girder Gantry Crane: This type has one horizontal beam (girder) and is suitable for lighter loads and shorter spans.

- Double Girder Gantry Crane: With two horizontal beams (girders), these cranes offer greater load capacity and are used for heavier loads and longer spans.

- Adjustable Height Gantry Crane: Designed with adjustable legs to accommodate varying load heights and uneven terrain.

- Rail-Mounted Gantry Crane: Equipped with wheels that run on rails, allowing for precise movement along a fixed path.

Functions:

- Lifting and Lowering: The primary function is to lift and lower heavy loads with precision, controlled by an operator.

- Horizontal Movement: Gantry cranes can move loads horizontally along a defined path, providing flexibility in material handling.

- Precise Positioning: These cranes are capable of precise load placement, making them suitable for delicate or intricate operations.

- Versatility: Gantry cranes can adapt to various applications and load types, thanks to their mobility and customization options.

Application Environments:

- Indoor: Gantry cranes are commonly used indoors in manufacturing plants, warehouses, and factories.

- Outdoor: Some gantry cranes are designed for outdoor use and can withstand exposure to weather conditions.

- Hazardous Environments: In industries such as mining or oil and gas, specialized gantry cranes are used in potentially hazardous environments, often with explosion-proof features.

- Clean Rooms: Precision manufacturing processes, such as semiconductor production, may require gantry cranes in clean room environments with strict cleanliness standards.

- Ports and Shipyards: Gantry cranes in these environments must handle saltwater exposure and challenging weather conditions.

In summary, 5 ton gantry cranes find applications in a wide range of industries, offering versatility, precision, and mobility in lifting and material handling tasks. The choice of gantry crane type and its suitability for specific applications depends on load requirements, span, environment, and customization needs.

Engineering Excellence: How 5 Ton Gantry Cranes Revolutionize Industrial Operations

Industrial operations demand precision, safety, and efficiency. 5 ton gantry cranes stand as symbols of engineering excellence in this regard. In this part, we will uncover how these cranes have redefined industrial operations by enhancing processes, improving safety, and optimizing efficiency.

Engineers have meticulously designed 5 ton gantry cranes to ensure they meet the unique requirements of industrial settings. Whether it's in manufacturing, construction, or warehousing, these cranes have become indispensable tools. Their engineering prowess shines through in their ability to handle heavy loads with precision and reliability.

Safety is a paramount concern in industrial applications, and engineers have integrated advanced safety features into these cranes. From load monitoring systems to collision avoidance mechanisms, 5 ton gantry cranes are engineered to protect both operators and assets.

Engineering Applications of 5 Ton Gantry Cranes Projects

The true measure of engineering excellence lies in real-world applications. In this subsection, we provide a detailed look at how 5 ton gantry cranes are deployed across various industries. Engineers and industry professionals will gain insights into the practical uses of these cranes, discovering how they solve unique engineering challenges.

5 Ton Outdoor Crane Installed in Electricity Factory Saudi Arabia

5 ton gantry crane for sale Saudi Arabia in Electricity Factory for outdoor use. Cost-effective 5 ton outdoor gantry crane for sale Saudi Arabia. Read on. .

Single Girder EOT Crane & Gantry Cranes 5 Tons for sale Sri Lanka

Single girder cranes 5 tons for sale Sri Lanka. Remote control single girder eot crane & single girder gantry crane with remote control for sale Australia. .

2 Ton & 3 Ton Jib Crane & 5 Ton Gantry Crane for Saudi Arabia

4 sets of 2 ton manual jib cranes, 1 set of 3 ton electric slewing jib crane & 5 ton gantry crane for sale Saudi Arabia good price. Check now. .

Portable Gantry Crane 5 Ton Drawing , Aluminum Gantry Crane & Steel Gantry

5 ton portable gantry crane for sale. Custom A frame gantry, with fixed height & adjustable gantry crane design, made of aluminum & steel, for light loads handling. .

5 Ton Portable Gantry Cranes for Hoisting 18 M Long Pipelines

2 sets of 5 ton portable gantry cranes for 18 M long pipeline installation in power station, simultaneous operation.5 ton portable gantry crane FOR SALE. .

5 Ton Portable Gantry Crane for Sale, Non-Rail Gantry Crane

Portable gantry crane 5 ton for sale. Castor mounted small gantry, non-rail gantry crane design for light loads hoisting. Check 5 ton portable crane for Canada. .

- In construction, for example, 5 ton gantry cranes play a pivotal role in lifting heavy building materials and equipment to great heights. Their precise engineering ensures that delicate operations, such as placing structural elements, are carried out flawlessly.

- In manufacturing, these cranes streamline production by efficiently moving raw materials and finished products. Their adaptability in handling different loads makes them versatile tools for optimizing manufacturing processes.

- Warehousing applications benefit from the space-saving design of 5 ton gantry cranes. Engineers have designed them to maximize vertical space, allowing for efficient storage and retrieval of goods.

As we delve into the industrial applications of 5 ton gantry cranes, we gain a deeper understanding of their versatility and adaptability. Engineers and professionals across diverse industries rely on these cranes to achieve precision, safety, and efficiency in their operations. Join us as we continue to explore the real-world engineering applications that highlight the significance of 5 ton gantry cranes in various industrial sectors.

Engineering Considerations for Brand New and Pre-Owned Gantry Cranes

As we delve deeper into the world of 5 ton gantry cranes, we encounter an important decision-making point: whether to invest in brand new or pre-owned units. This section focuses on the engineering considerations that come into play when evaluating these options. We explore the technical aspects of new 5 ton gantry cranes and offer insights into assessing the engineering value of pre-owned units.

Engineering Investments: The Technical Aspects of New 5 Ton Gantry Cranes

Investing in a brand new 5 ton gantry crane involves a careful evaluation of technical aspects. Engineers and decision-makers must consider the specifications, customization options, and the latest engineering innovations to meet their specific operational requirements.

New cranes offer the advantage of cutting-edge technology and engineering excellence. Engineers play a pivotal role in selecting the right configuration, control systems, and safety features to match the unique demands of their industry and application. Understanding the technical specifications and the latest advancements is essential for making an informed investment in a new crane.

Evaluating Engineering Value: The Technical Insights of Pre-Owned Units

For those exploring cost-effective alternatives, pre-owned 5 ton gantry cranes present a viable option. However, assessing the engineering value of pre-owned units requires a deep understanding of the technical insights involved.

Engineers must conduct thorough inspections to ensure that pre-owned cranes meet safety and performance standards. Refurbishments and upgrades may be necessary to maintain engineering integrity. Engineers also play a crucial role in developing strategies to extend the lifespan of these units while optimizing their performance.

The decision to invest in new or pre-owned 5 ton gantry cranes involves careful engineering considerations. This section equips engineers and decision-makers with the knowledge needed to evaluate technical aspects and make informed choices. Whether opting for the latest engineering innovations or exploring cost-effective alternatives, understanding the engineering value is paramount. Join us as we continue to navigate the technical landscape of 5 ton gantry cranes, exploring the intricacies of equipment selection.

Advantages of New 5 Ton Gantry Cranes:

Latest Technology: New cranes come equipped with the latest engineering advancements, ensuring optimal performance, safety, and efficiency.

Warranty: Typically, new cranes come with warranties that cover repairs and maintenance, providing peace of mind.

Customization: Engineers can tailor new cranes to meet specific operational requirements, including load capacity, span, and control systems.

Long Lifespan: Properly maintained new cranes can have a longer operational lifespan, offering value over an extended period.

Lower Maintenance: New cranes generally require less maintenance initially, reducing downtime and operational disruptions.

Limitations of New 5 Ton Gantry Cranes:

Higher Initial Cost: New cranes often involve a higher upfront investment due to the cost of cutting-edge technology and customization.

Lead Time: The process of ordering, manufacturing, and delivering a new crane may result in longer lead times before it's operational.

Advantages of Used 5 Ton Gantry Cranes for Sale:

Cost Savings: Used cranes are typically more affordable upfront, making them a cost-effective option for budget-conscious buyers.

Quick Deployment: Used cranes are readily available, and their installation and setup can be faster than ordering and waiting for a new crane.

Proven Performance: Well-maintained used cranes have a track record of performance and reliability.

Immediate Availability: Buyers can acquire a used crane almost immediately, reducing downtime in operations.

Limitations of Used 5 Ton Gantry Cranes for Sale:

Limited Customization: Used cranes may not offer the same level of customization as new ones, limiting their adaptability to specific needs.

Uncertain History: The condition and maintenance history of used cranes can vary, posing a risk if not properly inspected.

Shorter Remaining Lifespan: Depending on their age and condition, used cranes may have a shorter remaining operational lifespan.

Potential Maintenance Costs: Older used cranes may require more frequent maintenance and repairs, increasing operating costs.

Now, let's present this information in a table format for a clear visual comparison:

| Aspect | New 5 Ton Gantry Cranes | Used 5 Ton Gantry Cranes for Sale |

|---|---|---|

| Latest Technology | Yes, equipped with the latest engineering advancements | Dependent on the crane's age and condition |

| Warranty | Typically comes with warranties for repairs and maintenance | May or may not have warranties, depending on the seller |

| Customization | Can be tailored to meet specific operational requirements | Limited customization options |

| Long Lifespan | Can have a longer operational lifespan with proper maintenance | Operational lifespan may be shorter, depending on age and condition |

| Lower Maintenance | Generally requires less maintenance initially | May require more frequent maintenance and repairs |

| Higher Initial Cost | Yes, often involves a higher upfront investment | More affordable upfront |

| Lead Time | May have longer lead times before becoming operational | Readily available for quicker deployment |

| Proven Performance | Performance and reliability are assured with new equipment | Performance depends on the crane's maintenance history |

| Immediate Availability | Longer waiting time for order fulfillment | Can be acquired almost immediately |

Engineering Challenges and Solutions for 5 Ton Gantry Crane Users

As for heavy lifting and material handling, the challenges faced by users of 5 ton gantry cranes are diverse. Engineers and operators must navigate the complexities of safety, efficiency, and reliability. This section addresses these user challenges and explores the technical support and service that ensure a smooth engineering experience.

Engineering for Safety, Efficiency, and Reliability: Tackling User Challenges

Safety, efficiency, and reliability are paramount concerns for users of 5 ton gantry cranes. In this part, we dive into the engineering challenges and solutions that address these critical user requirements.

Safety engineering plays a pivotal role in crane operations. Engineers must develop and implement safety measures that protect operators, bystanders, and valuable assets. This includes load monitoring systems, emergency stop mechanisms, and collision avoidance technologies.

Efficiency engineering focuses on optimizing crane operations. Engineers are tasked with streamlining processes, reducing downtime, and enhancing overall productivity. Precision control systems, ergonomic designs, and predictive maintenance strategies are all part of the engineering solutions that contribute to operational efficiency.

Reliability is a key user expectation. Engineers must design 5 ton gantry cranes with durability and long-term performance in mind. This involves selecting robust materials, ensuring regular maintenance, and creating designs that withstand the rigors of industrial use.

Technical Support and Service: Ensuring a Smooth Engineering Experience

Smooth operations depend on responsive technical support and service. In this subsection, we explore how manufacturers and suppliers play a crucial role in resolving technical issues, optimizing crane performance, and ensuring a seamless engineering experience.

Engineers and operators rely on technical support for troubleshooting and problem-solving. Manufacturers and suppliers must provide comprehensive assistance to address any technical challenges that may arise during crane operation.

Scheduled maintenance and inspections are essential for crane longevity. Service engineers work closely with users to ensure that maintenance schedules are adhered to, minimizing unexpected downtime and extending the crane's lifespan.

Ensuring a smooth engineering experience involves a collaborative effort between users and service providers. This section equips engineers and operators with insights into the technical support and service ecosystem, highlighting the importance of a strong partnership in maintaining safe, efficient, and reliable crane operations.

Join us as we continue to explore the engineering challenges and solutions that enhance the user experience of 5 ton gantry cranes. We'll delve into the intricacies of safety, efficiency, and reliability, all underpinned by robust technical support and service.

Expert Engineering Insights: Frequently Asked Questions About 5 Ton Gantry Cranes

In the world of engineering, questions often arise, and clarity is paramount. This section serves as a valuable resource, providing expert responses to frequently asked engineering questions about 5 ton gantry cranes. Engineers and industry professionals will find in-depth answers that shed light on technical aspects, applications, and maintenance, ensuring comprehensive insights into these powerful lifting machines.

Engineering Clarity: In-Depth Answers to Common Questions

1. What are the key engineering components of a 5 ton gantry crane?

Engineers will gain a detailed understanding of the various components that make up a 5 ton gantry crane, from the steel structure to the control systems.

2. How does the control system of a 5 ton gantry crane work, and what engineering principles govern it?

The engineering intricacies of the control system, including load monitoring and precise positioning, will be explored in-depth.

3. What are the optimal maintenance practices for ensuring the long-term performance of a 5 ton gantry crane?

Engineers will find valuable insights into preventive and corrective maintenance strategies that extend the crane's lifespan and optimize its performance.

4. In which industrial applications can 5 ton gantry cranes be most effectively utilized from an engineering perspective?

Real-world examples and engineering considerations will illuminate the diverse range of industrial applications where these cranes excel.

5. What engineering innovations are on the horizon for 5 ton gantry cranes, and how will they impact their future applications?

Engineers will gain a glimpse into the future of 5 ton gantry cranes, including emerging technologies and engineering advancements.

As we conclude our exploration of the technical landscape of 5 ton gantry cranes, we provide engineering clarity by addressing the common questions and challenges faced by professionals in the field. Expert insights will empower engineers and industry enthusiasts with the knowledge needed to navigate the complexities of these powerful lifting tools, ensuring that questions are answered, and engineering excellence prevails. Join us as we unravel the final chapter of our journey through the world of 5 ton gantry cranes.

Conclusion:

In the world of engineering, precision and innovation reign supreme, and 5 ton gantry cranes exemplify these qualities. Through this comprehensive guide, we've embarked on an engineering journey, dissecting the intricacies of these remarkable lifting machines. Whether you're a designer, an operator, or a maintainer, understanding the engineering marvel that is the 5 ton gantry crane is essential to achieving precision, efficiency, and safety in your endeavors.

Engineering Innovation: Harnessing the Potential of 5 Ton Gantry Cranes

The engineering innovations embedded in 5 ton gantry cranes are a testament to human ingenuity. These machines are not merely tools; they represent the pinnacle of engineering excellence. By harnessing the potential of 5 ton gantry cranes, engineers can transform the way industries operate, optimizing processes, increasing productivity, and ensuring safety.

Your Next Engineering Challenge: Choosing the Perfect 5 Ton Gantry Crane

As you navigate the diverse landscape of engineering challenges, your next challenge may well be selecting the perfect 5 ton gantry crane. Armed with the knowledge gained from this guide, you're equipped to make informed decisions tailored to your specific operational needs. Whether you opt for a new crane with cutting-edge engineering features or a pre-owned unit that offers cost-efficiency, your choice will shape the trajectory of your engineering success.

For more information, technical specifications, or inquiries regarding 5 ton gantry cranes, please don't hesitate to contact us. We are dedicated to providing engineering solutions that elevate your operations to new heights. In the ever-evolving world of engineering, let innovation and precision guide your path to success.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch