Euro Single Girder Gantry Crane 15 Ton for Sale New Zealand Case

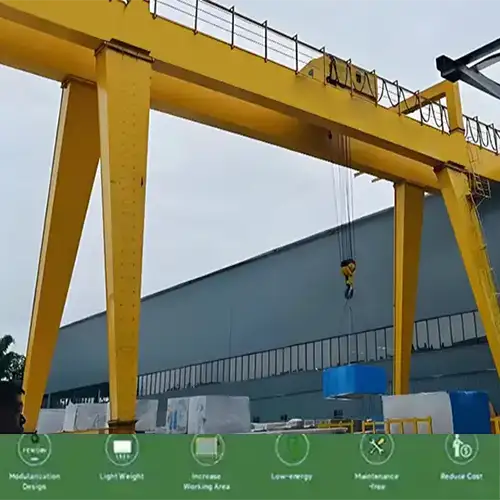

Check 15 ton European-style single girder gantry crane installed in a New Zealand steel workshop, showcasing efficiency, safety, and customization.

| Crane Type | Euroepan style gantry crane single girder |

| Crane Capacity | 15 ton |

| Crane Span | 12 meters |

| Lifting Height | 8 m |

| Crane Power | 400V, 50Hz, 3 Phase |

Category: 15 Ton Gantry Crane

Your Trusted 15 Ton Gantry Crane Manufacturer & Supplier

15 Ton Gantry Crane for Sale New Zealand

Case Study: European Style 15 Ton Single Girder Gantry Crane for New Zealand Steel Workshop Factory

Introduction

New Zealand’s steel fabrication industry is expanding, driving higher demand for efficient and reliable lifting systems. Among the preferred options are European-style single girder gantry cranes, valued for their compact design, smooth operation, and low maintenance.

This project involved supplying a 15-ton European-style gantry crane for a steel workshop factory in New Zealand. The workshop needed a lifting solution to handle steel beams and plates safely while complying with local 400V / 50Hz electrical standards.

The crane was customized with a wireless remote control system, European-standard components, and adjusted cable color coding to meet New Zealand regulations.

Close collaboration between the steel structure builder and the crane engineering team ensured accurate design matching, efficient shipment, and smooth installation. Together, they achieved a lifting system perfectly suited to the workshop’s layout and production needs — a practical example of how European-style cranes can be adapted for overseas industrial projects.

Project Overview

The project took place in New Zealand, within a steel workshop construction and fabrication environment. The end user was a steel processing factory focusing on fabricating and assembling steel structures for industrial use.

A local steel structure supplier acted as the project partner, helping the end user coordinate the crane selection, technical communication, and procurement process. This cooperation ensured that the crane specifications matched both the workshop layout and the client’s production needs.

Project Objectives

- Provide a high-efficiency lifting solution:

The gantry crane was designed to streamline the movement of steel components such as beams and plates within the workshop, improving overall workflow and safety. - Deliver a low-maintenance system:

Using a European-style design, the crane offers smoother operation, reduced noise, and minimal maintenance requirements compared with conventional models. - Ensure compliance with New Zealand standards:

Electrical configurations, cable color coding, and control systems were customized to meet New Zealand’s 400V, 50Hz, 3-phase power standard and local installation requirements.

Overall, the project aimed to combine performance, safety, and compliance — creating a lifting system that fits seamlessly into the factory’s steel fabrication operations.

Technical Specifications

The 15-ton gantry crane supplied for this project was designed in the European single girder style, known for its compact structure, lightweight components, and precise control performance. The configuration was carefully selected to match the workshop’s working conditions, span requirements, and lifting tasks. All technical parameters were finalized through coordination between the engineering and fabrication teams to ensure smooth installation and reliable long-term operation.

Below are the key technical specifications for the gantry crane used in the New Zealand steel workshop project:

| Item | Description |

|---|---|

| Crane Type | European Style Single Girder Gantry Crane |

| Rated Capacity | 15 Ton |

| Span | 12 meters |

| Lifting Height | 8 meters |

| Lifting Mechanism | 15-ton European-style wire rope hoist |

| Lifting Speed | 3.5 m/min (Single Speed) |

| Cross Travel Speed | 20 m/min |

| Long Travel Speed | 20 m/min |

| Control Mode | Wireless Remote Control |

| Duty Group | A3 |

| Power Supply | 400V, 50Hz, 3 Phase |

| Main Electrical Components | Schneider / ABB |

The crane’s design ensures quiet operation, smooth movement, and accurate load positioning, which are essential for workshop applications involving steel component handling. Its European-style hoist provides better balance between lifting speed and precision, making it ideal for steady, low-frequency material movement in steel fabrication workshops.

In addition, the use of international-grade electrical components such as Schneider and ABB enhances system reliability and simplifies maintenance. The overall setup is well-suited for indoor environments where efficiency, safety, and ease of operation are top priorities.

Customization for New Zealand Standards

The gantry crane was tailored to meet New Zealand’s electrical and operational requirements for smooth, safe, and reliable performance.

- Electrical Adaptation: Cable colors adjusted to comply with local wiring standards.

- Power Configuration: Compatible with 400V / 50Hz, 3-phase workshop systems.

- Safety Compliance: European-style hoist with overload protection and emergency stop functions.

- Control Optimization: Wireless remote control for flexible and safe operation.

- Design Fit: Structure aligned with the workshop span and steel columns for smooth installation.

These adjustments ensured the crane could operate efficiently, safely, and seamlessly within the local workshop environment.

Project Implementation Process

To ensure the gantry crane was delivered and installed smoothly, the project followed a structured approach that covered design, manufacturing, shipment, and on-site support. Each stage focused on aligning the crane with the workshop’s requirements while maintaining safety, reliability, and efficiency.

- Design Coordination: Verified lifting requirements, workshop layout, and runway dimensions; adjusted design to fit steel structure and ceiling height.

- Manufacturing & Quality: Components fabricated to European-style standards; electrical parts from Schneider/ABB for reliability and easy maintenance.

- Packaging & Delivery: Crane sections securely packed for sea transport with clear labels and documentation for quick assembly.

- Installation & Support: Provided manuals, wiring diagrams, and remote setup guidance; after-sales support ensured smooth commissioning and operation.

Project Outcome

The installation of the 15-ton European-style single girder gantry crane in the New Zealand steel workshop factory was completed successfully, fully meeting the project’s objectives.

The crane offers:

- Stable lifting performance – smooth operation even with heavy steel components.

- Low noise operation – ideal for indoor workshop environments.

- Precise control – ensures accurate placement of materials.

The system has significantly improved material handling efficiency, reducing the need for manual labor and minimizing operational risks. Workshop staff can now move steel beams and plates more quickly and safely, which helps maintain a steady production flow.

Feedback from the steel structure supplier and the end user was positive, noting that the crane fits the workshop layout perfectly and supports efficient day-to-day operations.

In summary, the project illustrates how a well-designed and customized European-style gantry crane can enhance productivity, safety, and workflow in steel fabrication facilities.

Key Takeaways

This project demonstrates several practical insights for deploying European-style single girder gantry cranes in workshops and factories.

- Efficiency and Reliability: Smooth lifting, stable performance, and energy-efficient operation make these cranes ideal for medium-duty steel handling.

- Adaptability: Electrical configurations, cable colors, and control modes can be customized to meet local standards, ensuring safe and reliable operation.

- Collaboration Benefits: Early coordination between crane engineers and workshop builders ensures accurate installation, proper fit, and long-term stability.

- Overseas Readiness: Technical customization and support allow these cranes to perform effectively in international workshops, meeting different power, safety, and operational requirements.

Overall, the project highlights the practical value of combining performance, flexibility, and collaborative planning for successful crane deployment.

Conclusion

The installation of the 15-ton European-style single girder gantry crane in the New Zealand steel workshop demonstrates how cranes can be customized for specific operational and local standards. By adapting both mechanical design and electrical systems, the crane was fully compliant with the workshop’s 400V / 50Hz power supply and wiring regulations, ensuring safe and reliable operation.

Key outcomes from the project include:

- Operational Efficiency: Smooth lifting, precise control, and low-noise operation improved workflow and reduced manual labor.

- Safety Compliance: Overload protection, emergency stop functions, and proper integration with the workshop layout enhanced workplace safety.

- Seamless Integration: Early collaboration between the crane engineers and steel workshop builders ensured accurate installation and minimized on-site adjustments.

- International Adaptability: The project highlights how European-style single girder cranes can be effectively deployed in overseas environments with proper customization and technical support.

In summary, this case provides a practical example of how European-style gantry cranes can meet diverse industrial requirements, delivering reliable performance, safety, and efficiency in international workshop and factory projects.

Related Products

Latest project

Workshop Overhead Crane 5 Ton & 10 Ton Buying Guide

Practical guide for selecting, installing, and maintaining 5 ton to10 ton workshop overhead cranes for safe, efficient, and reliable material handling.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch