15 Ton Gantry Crane Cost Guide | Pricing & Buyer Tips

Discover how much a 15-ton gantry crane costs. Learn key price factors, sample cost ranges, and practical tips for cost-effective crane purchases.

Category: 15 Ton Gantry Crane

Price Guide: How Much Does a 15 Ton Gantry Crane Cost?

When you’re looking to buy a 15-ton gantry crane, one of the first questions on your mind is probably: “How much will this cost me?” That’s exactly what this guide is for — to help buyers like you understand the pricing, key cost factors, and how to budget effectively before making a purchase. Knowing what influences the price can save you time, avoid unexpected expenses, and help you choose a crane that truly fits your operational needs.

Prices for a 15-ton gantry crane are not fixed. They vary widely depending on a few practical factors:

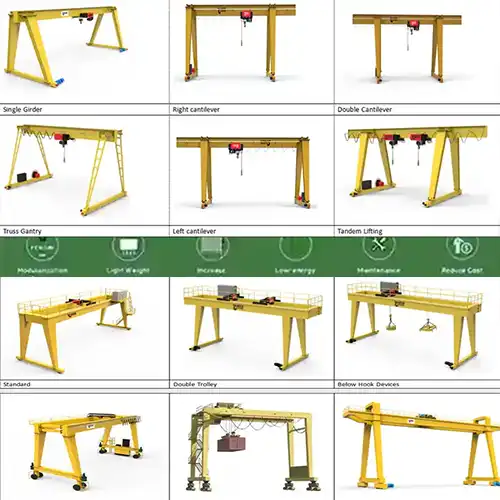

- Crane Type: Single girder, double girder, truss, L-type, or semi-gantry all have different material and fabrication costs.

- Span and Lifting Height: Longer spans and higher lifts require more steel, stronger motors, and extra structural support.

- Duty Class: Light-duty (A3) cranes cost less than heavy-duty (A5) models because the components are rated for less frequent use.

- Optional Features: Things like frequency-controlled drives, anti-sway systems, wireless remotes, or explosion-proof modifications can add to the total cost.

Understanding these factors upfront gives you a realistic view of what to expect. It also helps you communicate clearly with suppliers, so the quotations you receive are accurate and tailored to your site, rather than generic estimates that can be misleading.

In short, this guide is your roadmap for planning a practical, cost-conscious purchase of a 15-ton gantry crane, with no guesswork and no surprises.

Key Price Factors Buyers Should Know

Before budgeting for a 15-ton gantry crane, it helps to understand the main elements that influence cost. Knowing these factors allows buyers to make informed decisions, avoid surprises, and balance features with budget.

- Crane Type: Single girder, double girder, truss-type, L-type, or semi-gantry — each varies in material, fabrication, and structural complexity.

- Span and Lifting Height: Longer spans or higher lifts require more steel, stronger motors, and taller columns, increasing costs.

- Duty Class: Light-duty (A3) cranes cost less than heavy-duty (A5), which need reinforced gears, motors, and components for frequent use.

- Control System & Drives: Pendant controls are more affordable; remote or frequency-controlled drives (VFD) add precision but increase price.

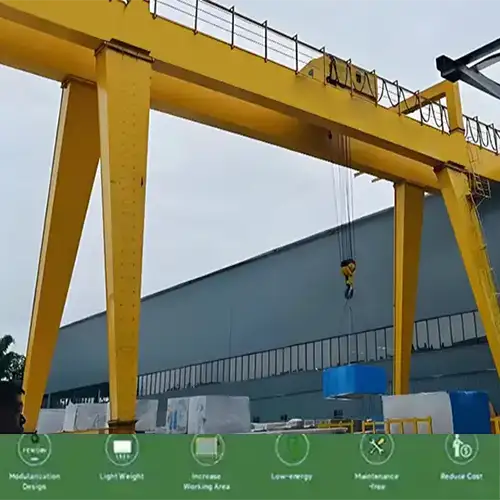

- Environmental Design: Indoor cranes are simpler; outdoor cranes require corrosion protection, trolley covers, and weatherproof systems.

- Optional Accessories: Anti-sway systems, overload displays, and explosion-proof features improve safety but add cost.

- Quantity & Shipping: Bulk orders can reduce per-unit cost; shipping depends on crane size, weight, and destination.

Sample Cost Table for Reference

To help buyers get a practical sense of pricing, here’s a reference table showing typical cost ranges for common 15-ton gantry crane configurations. Keep in mind these are approximate prices — actual costs depend on site requirements, optional features, and shipping.

| Crane Type | Typical Span | Duty Class | Approx. Price Range (USD) | Notes |

|---|---|---|---|---|

| MH Single Girder Gantry Crane | 12 m | A3 | $12,000–$16,000 | Standard indoor/outdoor use |

| Truss-Type Single Girder Gantry Crane | 16 m | A3 | $10,000–$14,000 | Lightweight, outdoor-friendly |

| L-Type Single Girder Gantry Crane | 20 m | A4 | $16,000–$22,000 | For long steel materials |

| European Single Girder Gantry Crane | 15 m | A5 | $18,000–$24,000 | Precise control, quiet operation |

| European Double Girder Gantry Crane | 20 m | A5 | $25,000–$35,000 | Heavy-duty, high-frequency use |

Buyer Tip: Use this table as a starting point for budgeting. Share your site details and optional requirements with suppliers to get a precise quotation tailored to your operation.

How Buyers Can Estimate Costs for Their Site

Estimating the cost of a 15-ton gantry crane for your specific site doesn’t have to be complicated. By following a few practical steps, buyers can create a realistic budget and avoid surprises later.

- Confirm Crane Type and Capacity: Decide whether you need a single girder, double girder, truss, L-type, or semi-gantry crane — all rated for 15 tons.

- Measure Span and Lifting Height: Accurately determine the width of your workspace and the maximum lifting clearance required.

- Decide Duty Class: Light (A3), medium (A4), or heavy-duty (A5) — choose based on how often the crane will be used.

- Include Optional Features: Consider anti-sway systems, overload displays, VFDs, or corrosion protection if your operation requires them.

- Factor in Shipping, Installation, and Local Taxes: Include transport costs, on-site assembly, and any applicable import duties or local taxes in your budget.

Buyer Tip: By collecting these details upfront, you can request accurate quotations from suppliers and ensure the crane you purchase fits both your operational needs and budget.

Buying Tips for Cost-Effective Purchase

When purchasing a 15-ton gantry crane, getting the best value goes beyond just picking the lowest price. Smart buyers focus on quality, suitability, and long-term costs. Here are some practical tips:

- Compare Suppliers Carefully: Look at multiple suppliers, but don’t compromise on quality or safety standards. A cheaper crane with poor components can cost more in repairs and downtime.

- Consider Modular or Semi-Gantry Cranes: These designs can save money in limited spaces or where a full double girder crane isn’t necessary. They are easier to assemble and maintain.

- Request Multiple Quotations: Include optional features like VFDs, anti-sway systems, or corrosion protection to see the full range of costs and choose the best combination of price and performance.

- Plan for Long-Term Maintenance: Factor in servicing, replacement parts, and energy consumption. A slightly higher upfront cost for a reliable crane can save money over its lifetime.

Buyer Tip: Treat the purchase as an investment in efficiency and safety, not just a one-time expense. This approach helps ensure the crane delivers consistent performance while staying within budget.

Conclusion

When it comes to a 15-ton gantry crane, there’s no fixed price — costs depend on a combination of factors like crane type, span, lifting height, duty class, control system, environmental protection, and optional accessories. Each site and operation has its own requirements, so a “one-size-fits-all” price simply doesn’t exist.

For buyers, the key to a successful and cost-effective purchase is providing detailed, site-specific information. This includes:

- Workspace dimensions (span, lifting height, headroom)

- Operational frequency (duty class)

- Power supply details (voltage, phase, frequency)

- Environmental conditions (indoor/outdoor, coastal or dusty locations)

- Optional requirements (anti-sway, VFD, explosion-proof, trolley covers)

By sharing this information with suppliers, you ensure they can provide accurate quotations, tailored design drawings, and the right configuration for your needs.

Ultimately, careful planning and informed decisions save money, prevent downtime, and guarantee that the crane operates efficiently and safely. Taking the time to evaluate your site and operational requirements means the crane you invest in will be reliable for years to come, while avoiding unexpected costs or performance issues.

Related Products

Latest project

Workshop Overhead Crane 5 Ton & 10 Ton Buying Guide

Practical guide for selecting, installing, and maintaining 5 ton to10 ton workshop overhead cranes for safe, efficient, and reliable material handling.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch