10 Ton Overhead Crane Price – Balancing Cost, Power & Frequency

Understanding how lifting height, span & duty cycle affect the cost—and how to avoid under-specifying or overpaying. Get your 10 ton overhead crane price!

Category: Ton & Price

Your Trusted 10 Ton Overhead Crane Manufacturer & Supplier

10 Ton Overhead Crane Price – Balancing Cost, Power, and Frequency

Introduction: Why the 10 Ton Crane Is a Crucial Choice Point

When you're looking at a 10 ton overhead crane, you're at a real decision-making point. It's not just about how much weight the crane lifts—it’s about how often it works, how high it lifts, and how far it travels.

For many buyers, this is where things get serious. Why? Because 10 tons sits right at the middle ground—it’s too heavy for basic light-duty cranes, but doesn’t always need the full structure of a high-capacity system. That’s where careful judgment comes in.

You’re likely choosing between two paths: a single girder crane that’s simpler and cheaper, or a double girder crane that can offer more power, stability, and lifting height.

If you choose wrong, you might end up with something that wears out too fast—or worse, something you paid too much for and don’t fully use.

Here’s what makes the 10 ton capacity a unique crossroad:

- Tipping Point for Design Choice- Most buyers at this level are weighing single girder vs. double girder designs. It’s one of the few load ranges where both can technically work, but performance and lifetime vary a lot depending on application.

- Wide Range of Applications- A 10 ton crane could be used in anything from mold handling to steel fabrication, machine loading, or storage yards. But usage frequency and working environment will heavily affect which crane structure you need.

- Big Differences in Cost and Capabilities- The price jump from single girder to double girder can be large. But so can the benefits: higher lifting height, longer span capacity, better hook approach, and longer service life under heavy use.

- Need to Balance Three Critical Factors- You’ll need to balance cost, lifting power, and working frequency—or you risk either under-buying or over-paying. We’ll walk through what that balance looks like step-by-step.

Price Range Snapshot: What Should You Expect to Pay?

If you’ve started asking around or collecting quotes, you’ve probably noticed how wide the price range is for 10 ton overhead cranes. That’s because price depends on much more than just the lifting capacity.

Let’s start with the basic numbers and then unpack what really drives those figures up or down.

Estimated Price Range (FOB China)

Here’s what you might expect to pay just for the crane itself—factory price, not including shipping or installation.

- 10 Ton Single Girder Overhead Crane:

Approx. $7,000–$15,000

A good choice for lower lifting height, shorter span, and lighter usage. Usually comes with a compact hoist and a simple structure. - 10 Ton Double Girder Overhead Crane:

Approx. $15,000–$35,000+

This version supports higher lifting heights and longer spans. It also allows for heavy-duty hoists and better hook travel. More steel, more power—more money.

Important Note:

These prices are FOB China (Freight on Board), which means they do not include:

- Overseas shipping

- Runway beams or structural supports

- Installation costs

- Control panels, electrification, or wiring beyond the crane unit

Budgeting for a complete crane setup? Expect total costs to be 1.5 to 2 times the FOB price depending on the site conditions and services needed.

What Drives the Cost Up or Down?

There’s a reason two quotes for a “10 ton crane” can differ by $10,000 or more. Here's what affects that:

Structural Design (Single or Double Girder) Double girders cost more due to heavier steel use, twin rail support, and added fabrication. But they allow higher lifts and better durability in demanding settings.

Lifting Height and Span The taller the lift or the wider the bridge span, the larger and stronger the crane needs to be.

- Taller lifting height = longer hoist rope, reinforced structure

- Longer span = heavier beam, increased end carriage size

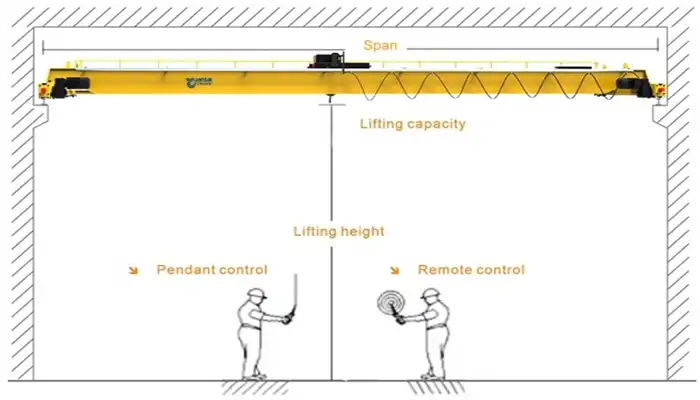

Control Method You’ll pay more for advanced control systems:

- Pendant control (wired): cheapest and basic

- Wireless remote: more flexible, adds cost

- Cabin control: for large workshops or outdoor yards, the most expensive setup

Frequency of Use and Duty Grade The more often you lift, the tougher your hoist and motors need to be.

- Light use (a few lifts/day): standard motor and gearbox

- Frequent or continuous use: higher-grade motors, better cooling, and stronger brakes

Custom Features and Certifications Add-ons raise the price but may be necessary:

- CE/ISO certification for compliance

- Explosion-proofing, corrosion resistance, or heat protection

- Inverter drives, variable speed controls, limit switches

These are often essential in industries like chemicals, foundry, or outdoor applications.

Two 10-ton overhead cranes may look the same on paper—but their specs and costs can be worlds apart. The better you understand what goes into the price, the easier it is to spot a quote that actually fits your job, not just your budget.

main specificaitons required for single girder overhead crane price

main specificaitons required for double girder overhead crane price

The Balancing Act: Cost, Power, and Frequency

Buying a 10 ton overhead crane isn’t just about picking something that lifts 10 tons. You need to weigh three things carefully—how much you’re willing to spend, how much performance your work demands, and how often you’re using it. The right balance ensures your crane won’t underperform or drain your budget.

Cost – Look Beyond the Price Tag

The upfront price is only part of the full cost. Buyers often overlook installation complexity, long-term service needs, or the impact of downtime when buying too cheap. It's not about finding the cheapest crane—it's about investing wisely.

| Cost Factor | Description | Impact |

|---|---|---|

| Crane Equipment Price | FOB China cost of crane & hoist | Single girder $7k–15k double girder $15k–35k+ |

| Installation Costs | Labor, tools, supports, wiring | Double girder more complex costly to install |

| Maintenance Over Time | Parts, service calls, downtime | Lower-grade needs more repairs |

| Total Ownership Cost | Purchase + install + upkeep (10–15 yrs) | Higher upfront may save long-term |

| Overbuying Risk | Paying for unused features | Wasted budget inefficiencies |

Power (Performance) – Match to Job Requirements

How high you lift, how far, and how fast all affect the power needed. Undersized hoists or motors may burn out early. Oversized ones may cost more than they’re worth. Choose power based on actual lifting height and duty cycle.

| Performance Factor | Description | What to Consider | Effect on Price |

|---|---|---|---|

| Hoist Motor Size | Affects lifting speed and heat resistance | Bigger motors for frequent lifts | Higher power means higher cost |

| Lifting Height | Hook travel distance | Taller lifts need stronger hoists | More height raises cost |

| Duty Cycle | How often crane runs | Frequent use needs stronger parts | Higher duty increases price |

| Girder Structure | Single or double girder | Double for heavier lifting | Double girder costs more |

| Control Precision | Load movement accuracy | Inverter drives improve control | Better control adds cost |

Frequency – Match Crane to Daily Workload

Usage frequency is one of the most critical—yet most overlooked—factors. Choosing the wrong FEM or ISO duty classification leads to early failure or wasted spending. Always match the crane’s work class to the reality of your shop floor.

| Usage Level | Typical Scenario | Suggested Design & Classification | Cost & Price Impact |

|---|---|---|---|

| Light Use | 1–2 lifts/hour 4–5 hours/day Non-continuous work | Single girder FEM M3–M4 Standard motor & gearbox | Lower upfront cost Lower maintenance costs |

| Moderate Use | 3–5 lifts/hour Partial shift use | Upgraded hoist FEM M5 Better brake & cooling | Moderate cost increase Longer lifespan Less downtime |

| Heavy Use | 5+ lifts/hour Multiple shifts/day Repetitive production | Double girder FEM M6+ Industrial hoist & drives | Higher initial investment Lower repair frequency Higher reliability |

| High Environmental Load | Dust, heat, outdoor Exposure | Sealed motors Corrosion protection Explosion-proofing | Additional cost for protection Prevents costly failures Ensures safety |

| Misclassification Risk | Using light-duty crane for heavy-duty tasks | Early failures Excessive wear Unplanned downtime | Higher repair & replacement costs Lost production time |

Lifting Height, Span, and Travel Distance – Hidden Price Influencers

Many buyers focus on lifting capacity but overlook how the crane fits into their actual workspace. The lifting height, bridge span, and travel distance all have a big impact on crane design—and the final price. These aren't optional specs; they directly affect the type of hoist, girder, and motor systems needed.

Ignoring them can lead to costly redesigns or installation headaches. Let’s look at what each one really means in practice.

Lifting Height – More Than Just a Vertical Number

The lifting height is how far the hook needs to travel vertically—from the floor (or pit) to the highest lift point. The higher you go, the more compact and efficient your crane design must be.

| Lifting Height Scenario | Description | Effect on Crane Design and Cost |

|---|---|---|

| Standard Height (6–9m) | Typical for most workshops with mid-ceiling height | Can use standard hoist and single girder setup |

| Low Headroom Workshop | Ceiling too low for standard hoist and trolley height | Requires low-headroom hoist or compact European-style design |

| Tall Bay or High Lift (10m+) | High-rack storage or vertical mold handling in tall facilities | May need double girder crane to support long lift and control |

| Below Ground Pit Use | Lifting from deep foundations or machinery pits | Needs longer wire rope high-duty hoist and reliable control |

| Hook Clearance Issues | Limited space between beam and ceiling | Compact hoist and careful girder selection needed |

Practical Tip: Always confirm minimum and maximum hook positions and any obstructions above or below the load area before choosing crane type.

Span – How Wide Is the Bay?

The span is the horizontal distance the crane needs to cross, usually matching the width of your workshop or bay. Larger spans demand stronger beams, which increases both structural cost and the size of end carriages.

| Span Width | Description | Effect on Crane Cost and Structure |

|---|---|---|

| Short Span (<12m) | Narrow workshop or compact facility | Standard beam and end trucks economical setup |

| Medium Span (12–20m) | Common in general manufacturing spaces | Needs moderate beam strength attention to deflection control |

| Large Span (20m–30m) | Found in steel mills, warehouses, or open bay layouts | Requires stronger double girders custom end trucks |

| Very Large Span (30m+) | Specialized applications (e.g., aerospace or heavy steel handling) | Custom engineering heavier structure high material cost |

| Deflection Consideration | Longer spans must control vertical bending (deflection) | May require higher-grade steel camber-designed beams |

Practical Tip: Always ask your supplier for deflection limits and allowable tolerances—too much sag in the beam affects hoist performance and safety.

Travel Distance – Don’t Forget the Runway Length

The travel distance is how far the crane moves along the workshop. The longer it travels, the more electrical cable, rails, and alignment systems it needs. This part is often left out of budget discussions—until the cost of rail, power track, or travel drives surprises you.

| Travel Distance | Description | Impact on Crane System and Cost |

|---|---|---|

| Short Runway (<20m) | Basic setup often for workstation cranes or small production lines | Simple electrification standard travel drives |

| Medium Runway (20–50m) | Suitable for medium-size production halls or maintenance shops | Requires better cable management power lines or festoon systems |

| Long Runway (50m+) | Needed for large factories or warehouse loading zones | Demands upgraded travel motors cable reels and track straightness |

| Outdoor or Exposed Runs | Cranes used outdoors or semi-covered areas | Needs weatherproof rails covered electrification rust-proofing |

| Alignment Needs | Longer runways need accurate rail alignment | Misalignment can cause wheel wear or motor strain |

Practical Tip: For runways over 30 meters, discuss rail leveling, expansion joints, and electrification methods during the design stage—not after the order.

Avoid These Costly Buyer Mistakes

Buying a 10 ton overhead crane isn't just about picking the strongest or cheapest option. There are some common pitfalls that many buyers fall into—mistakes that can end up costing you more time and money in the long run. Let's go through the biggest traps and how to avoid them.

Under-Specifying Duty Class: A Shortcut to Early Failure

One of the most frequent errors is choosing a light-duty hoist for a job that demands heavy, frequent lifting. It might save money upfront, but don’t be fooled—this decision often leads to equipment breaking down faster than you expect.

- Light-duty hoists aren’t built to run constantly or lift heavy loads repeatedly.

- Overheating motors and worn-out brakes are common results.

- The downtime and repair costs quickly outweigh any initial savings.

- Always match the duty class (like FEM or ISO ratings) to your actual daily workload.

Think of it like buying a small car to haul a heavy trailer—it just won’t hold up.

Overpaying for Unnecessary Double Girder Cranes

A double girder crane might sound impressive and reliable, but not every 10 ton lifting job needs one. Especially with modern low-headroom single girder cranes, many tasks can be done safely and efficiently without the extra cost.

- Double girders mean higher upfront costs for the crane and installation.

- They also require stronger runway beams and more complex foundations.

- Single girder cranes with low-headroom hoists can be perfect for tighter spaces.

- Make sure your supplier helps you weigh whether the double girder is truly needed.

Don’t fall into the trap of “bigger is always better”—sometimes it’s just bigger and more expensive.

Neglecting Installation Layout: It’s More Than Just Buying a Crane

Even if you pick the right crane, ignoring your workshop’s physical layout can create big headaches later. Overhead obstructions, insufficient beam height, and runway design all affect how well the crane fits and functions.

- Overhead pipes, lighting, or ductwork can limit crane movement.

- Beam height must accommodate hoist dimensions and hook clearance.

- Runway rails need proper alignment and support for smooth travel.

- Poor layout planning leads to restricted crane use and safety risks.

Always do a detailed site survey before finalizing the order. Measure everything twice, if you can.

Failing to Ask for Full Itemized Quotes: Hidden Costs Add Up

The price tag on the crane itself is just the beginning. Many buyers don’t realize that shipping fees, runway beams, electrical panels, and installation charges often match—or even exceed—the crane cost.

- Ask suppliers for a breakdown of all costs, not just the crane price.

- Shipping heavy equipment internationally can be expensive and slow.

- Runway beams and support structures may require special materials.

- Installation labor, wiring, and testing are often billed separately.

- Neglecting these expenses can blow your budget and delay your project.

Make sure you get a clear, detailed quote before signing anything. It’ll save you surprises down the line.

Single Girder vs. Double Girder: Which Fits Your Needs?

When it comes to choosing between single girder and double girder cranes, it’s all about matching the right system to your specific needs. There’s no one-size-fits-all answer—each design comes with its own set of advantages depending on your project requirements.

Feature Comparison: Single Girder vs. Double Girder

| Feature | Single Girder | Double Girder |

|---|---|---|

| Initial Cost | Lower—cost-effective for light to medium use | Higher—extra materials and installation costs |

| Lifting Height | Moderate (limited by headroom and hoist type) | High—offers more clearance for large lifts |

| Span Capability | Up to ~25m | Up to ~35m+ |

| Hoist Type | Underslung or top-mounted hoist | Hoist fixed between girders |

| Maintenance Access | Limited—less space for repairs | Easier access—more room for maintenance |

| Power Efficiency | Better for light or infrequent use | Better for heavy-duty, frequent use |

| Common Use | Fabrication, warehousing, light lifting | Steel mills, foundries, mold handling, heavy-duty |

Single Girder Crane – Best for Light to Medium Duty

- Cost: Single girder cranes are the go-to for cost-effective lifting in smaller or medium-duty applications.

- Best For: If you’re running a warehouse, small fabrication shop, or handling smaller loads, a single girder crane will do the job without breaking the bank.

- Lifting Height and Span: While they provide decent lifting height and span (typically up to 25 meters), they are not ideal for high lifts or larger bays.

- Maintenance: Maintenance is a bit more tricky, as it’s harder to access components. However, these cranes don’t usually require as much maintenance due to lighter workloads.

Double Girder Crane – Best for Heavy-Duty, High-Frequency Work

- Cost: The double girder crane will hit your wallet harder initially, but it’s built for high-frequency and heavy-duty work, making it worth the investment for tougher tasks.

- Best For: These cranes are ideal for heavy-duty industries like steel mills, foundries, and mold handling, where you need maximum lifting height and span.

- Lifting Height and Span: Double girders allow for higher lifting heights (with greater clearance) and wider spans (up to 35 meters and beyond).

- Maintenance: While they are easier to maintain due to the more spacious design, the extra parts and structure can add complexity.

Practical Buyer Tips: Get the Best Value

Buying a 10 ton overhead crane is a big investment, so you want to make sure you're getting the best bang for your buck. It's not just about the sticker price—details matter when it comes to performance, safety, and long-term costs.

Here are some practical tips to help you ask the right questions and avoid surprises.

Know What to Ask For

Before you commit, request key technical documents from your supplier. These will help you understand exactly what you're getting and how the crane will perform in your environment.

- Ask for load charts showing how much weight the crane can safely lift at different spans and heights.

- Request detailed drawings so you can check dimensions and clearances against your workshop.

- Clarify the FEM duty class or ISO rating—this tells you if the crane is built for light, moderate, or heavy use.

Get Clear on Technical Specs

Don't guess or assume—be clear about the details that affect daily operation and maintenance.

- Ask about the lifting speed and if it meets your production pace.

- Check the motor insulation class to ensure it suits your working environment (hot, dusty, humid, etc.).

- Find out the hoist travel method—whether it's pendant control, radio remote, or cabin operated.

Share Your Site Power Details Early

Electrical compatibility is a big deal, so provide your power supply specs upfront.

- Voltage, frequency, and phase details help the manufacturer design a crane that won't cause electrical headaches.

- Early sharing avoids delays or costly redesigns later.

Think About the Future

Even if you don't need a heavy-duty crane right now, consider whether you might expand operations.

- A crane that can handle slightly higher capacity or faster speeds later might save you from buying a new one down the road.

- Future-proofing your investment is smart, especially if your business is growing.

Compare Apples to Apples

Don't just accept one quote—ask for both single girder and double girder crane quotations.

- This helps you weigh the total cost of ownership including installation, maintenance, and operational efficiency.

- You might find a more economical single girder crane that meets your needs without the extra expense.

These tips help you stay informed, negotiate better, and choose a crane that fits your real requirements—not just the biggest or cheapest option.

Requesting a Quote the Right Way

Getting a quote for your 10-ton overhead crane should go beyond just asking for a price. To make sure you're getting exactly what you need (and avoid surprises later), you have to provide the right information from the start. Here's how to request a quote that fits your application perfectly.

Provide Working Frequency and Duty Cycle

Let your supplier know how often the crane will be used.

- Working frequency: How many lifts per hour or shifts per day will the crane handle?

- Duty cycle: Will it be operating for 4 hours a day or running multiple shifts?

This will help your supplier recommend the right motor, hoist, and duty class (light, medium, or heavy).

Share a Detailed Layout with Key Measurements

Give your supplier a clear picture of your workspace to avoid sizing issues.

- Provide the span, lifting height, and clearances to ensure the crane fits properly in your facility.

- Highlight any overhead obstructions (pipes, lights, etc.) that might affect the crane's operation.

This ensures your crane is designed for your specific space and function.

State Environmental Conditions

Cranes are built to withstand various environments, so it's important to tell your supplier where the crane will be used.

- Hot: If the crane will be exposed to high temperatures, you may need special insulation or materials.

- Dusty or hazardous: For harsh environments, like those in foundries or chemical plants, you may require explosion-proof or sealed systems.

Knowing your environment allows the manufacturer to select the right materials and coatings for durability.

Ask About Installation Guidance and Certifications

When you request a quote, be sure to ask about more than just the crane itself.

- Inquire about installation guidance or support. Will the supplier help you with setup or provide manuals?

- Confirm if the crane is CE, ISO, or third-party certified—important for safety and compliance.

- Ask about warranty coverage and post-sale support to ensure peace of mind after purchase.

These details protect you from unexpected costs and ensure the crane meets your safety and quality standards.

Conclusion: Choose Wisely, Not Just Cheaply

When it comes to the price of a 10 ton overhead crane, there’s a lot more at play than just the lifting capacity. It’s about finding the right balance between cost, power, and how often you’ll use it.

- Match your actual lifting needs to the right crane specifications.

- Avoid choosing a crane that’s underpowered and prone to breakdowns.

- Don’t waste money on features or capacities you won’t use.

Making the right choice up front isn’t just about saving money—it’s about safety, efficiency, and peace of mind. A well-chosen crane reduces downtime, keeps your team safe, and keeps your operation running smoothly.

Finally, work with a manufacturer or supplier who takes the time to ask the right questions and understand your unique needs. Your crane should be a reliable partner for years, not just a short-term purchase.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch