Electric Overhead Cranes for Agriculture, Your Crane Manufacturer

Revolutionizing Agriculture: The Power of Electric Overhead Cranes

In the vast expanse of the agriculture industry, where efficiency, precision, and safety are paramount, the role of machinery cannot be understated. Among the many tools that aid in streamlining agricultural operations, overhead cranes stand tall as unsung heroes. Their ability to lift, move, and position heavy loads with remarkable precision has made them indispensable in various facets of farming and agribusiness. But as technology advances, a new star is rising: the electric overhead crane.

Elevating Agriculture with Electric Overhead Cranes

Traditional cranes have served the agriculture industry faithfully for years, but the emergence of electric overhead cranes has brought about a transformational shift. These cutting-edge cranes harness the power of electricity to offer a multitude of advantages that set them apart from their predecessors.

One of the most significant benefits of electric overhead cranes is their exceptional energy efficiency. As sustainability becomes a global concern, these cranes shine as eco-friendly champions by consuming less energy compared to their non-electric counterparts. This not only reduces operational costs but also contributes to a greener agricultural landscape.

Precision and control are paramount in delicate agricultural tasks. Electric overhead cranes excel in this regard, offering operators the ability to handle loads with unparalleled accuracy. Whether it's moving fragile greenhouse plants or positioning equipment in tight spaces, these cranes make every movement a masterpiece.

Safety is a top priority in agriculture, where workers and livestock often share the same spaces. Electric overhead cranes come equipped with advanced safety features such as overload protection and emergency stops, ensuring that every operation is conducted with the utmost care.

Versatility is another hallmark of electric overhead cranes. They can be tailored to meet the specific needs of various agricultural tasks, from lifting heavy bulk materials to gently handling delicate crops. This adaptability makes them a valuable asset across a spectrum of farming operations.

Furthermore, the reduced noise and emissions of electric overhead cranes make them ideal for indoor use, contributing to a quieter and more eco-friendly agricultural environment.

Benefits of Electric Overhead Cranes in Agriculture

Energy Efficiency

In the fast-evolving world of agriculture, where every ounce of energy counts, a new hero has emerged: the electric overhead crane. These cranes are setting a new standard for energy efficiency that traditional cranes simply can't match.

Electric cranes operate on the principle of converting electrical energy into mechanical motion, minimizing wastage and maximizing output. This translates to a significant reduction in energy consumption when compared to their conventional counterparts. By tapping into this energy-efficient technology, agricultural operations can significantly lower their carbon footprint while reaping the rewards of reduced energy costs.

Precision and Control

Imagine the delicate task of positioning a fragile plant in a greenhouse or maneuvering heavy machinery with finesse. Electric overhead cranes bring a level of precision and control that is nothing short of astonishing.

Equipped with advanced control systems, these cranes allow operators to perform intricate movements with absolute accuracy. The ability to control the crane's motion down to the minutest detail ensures that even the most delicate agricultural tasks are executed flawlessly. This precision is invaluable, especially when dealing with tasks where accuracy is paramount, such as planting, harvesting, or moving livestock.

Safety Features

In agriculture, where human lives and livestock are intertwined, safety is non-negotiable. Electric overhead cranes come equipped with a suite of safety features that elevate them to the forefront of secure material handling.

Safety mechanisms like overload protection and emergency stops are integral to electric cranes, ensuring that operations cease immediately if any irregularities are detected. This is of paramount importance in an agricultural setting where the well-being of workers and livestock is at stake. With these safety measures in place, potential accidents are minimized, and the work environment becomes safer for everyone involved.

Versatility

Agricultural tasks can vary vastly, from lifting bulky bags of feed to gently handling delicate plants. This is where the versatility of electric overhead cranes shines through.

These cranes can be tailored and customized to fit the unique needs of different agricultural tasks. Whether it's attaching specialized lifting equipment or adjusting the crane's parameters, electric cranes can be adapted to handle a diverse range of loads and materials. This adaptability ensures that no matter the task at hand, an electric crane can rise to the occasion.

Reduced Noise and Emissions

In the hustle and bustle of agricultural operations, the tranquil sounds of nature can be drowned out by the roar of machinery. Electric overhead cranes, however, bring a welcome change to this soundscape.

By operating silently and emitting zero emissions, electric cranes create a quieter and cleaner working environment. This is particularly advantageous in indoor settings, where noise reduction is a priority. Additionally, the absence of emissions aligns perfectly with eco-friendly farming practices, contributing to a healthier planet and promoting sustainable agricultural operations.

In the modern agricultural landscape, where efficiency, precision, safety, versatility, and environmental considerations are paramount, electric overhead cranes stand as a testament to innovation. With their energy efficiency, precision control, safety features, adaptability, and reduced impact on the environment, these cranes are revolutionizing the way agriculture operates, setting a new standard for excellence and sustainability.

Types of Electric Overhead Cranes for Agriculture

Bridge Cranes: Power and Precision Above All

Picture a crane that spans the width of your workspace, allowing you to effortlessly move heavy loads from one end to the other with impeccable accuracy. That's the magic of bridge cranes. These heavy-duty workhorses are an engineering marvel designed to handle substantial loads and streamline material movement in various agricultural settings.

- Components and Mechanics: A bridge crane consists of a horizontal bridge that travels along parallel runways installed overhead. Suspended from the bridge is a trolley that moves back and forth, allowing the hoist to vertically lift and lower the load. The bridge and trolley movement can be controlled manually or electronically, granting operators precise control over load positioning.

- Agricultural Applications: In agriculture, bridge cranes find their niche in processing plants. Imagine a facility where harvested crops are transformed into packaged products. Bridge cranes come to life here, seamlessly transporting raw materials, intermediate products, and finished goods along production lines. Their high load capacity and precision make them ideal for heavy lifting and intricate material handling tasks.

Single girder overhead crane

Single girder overhead crane specifications: Capacity:3.2 ton to 16 ton, Span: 7.5m to 28.5m,Lifting Height: 6m to 18m,Working Class:A5.

Double girder overhead crane

Double girder overhead crane specifications: Capacity:5 ton to 100ton,Span: 10.5m to 31.5m,Lifting Height: 6m to 18m,Working Class:A5- A7.

Suspension crane

Underslung overhead crane specifications: Capacity:0.5 ton to 10 ton, Span: 3m to 31.5m, Lifting Height: 6m to 18m,Working Class:A3 to A5.

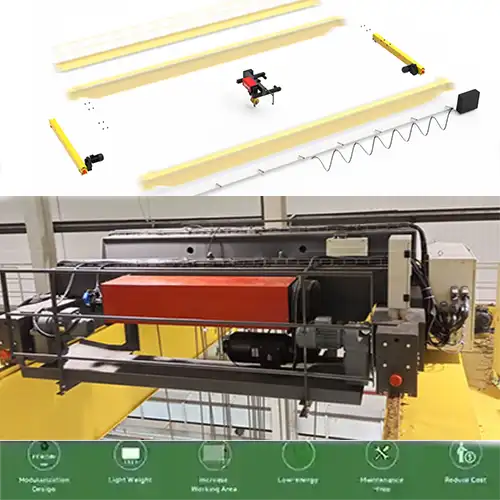

KBK crane

Overhead kbk crane specifications: Capacity: 125Kg-5000Kg,Lifting Height: 2.5m-12m,Maximum Span : 3-10m,Working Class: A3.

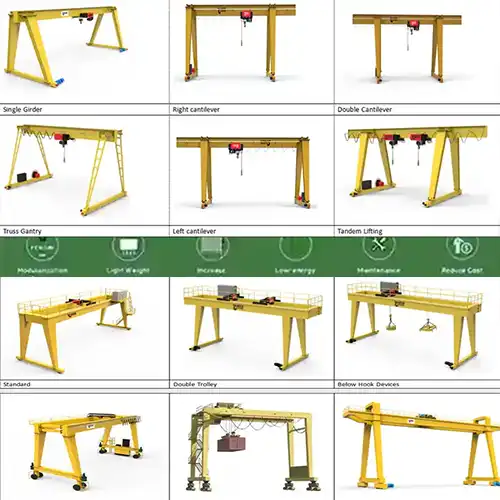

Gantry Cranes: Unleash Mobility and Muscle

When the need for mobility intersects with the demand for strength, gantry cranes step into the spotlight. These versatile giants are designed to traverse outdoor spaces, making them a stalwart companion in loading and unloading operations.

- Features and Mobility: Gantry cranes are characterized by their sturdy legs or supports that rest on the ground, providing stability even when carrying heavy loads. What sets them apart is their mobility - they can be wheeled along tracks or even designed to be self-propelled. This makes gantry cranes an ideal choice for agricultural settings that lack permanent overhead structures.

- Agricultural Applications: Picture a sprawling storage yard where bales of hay need to be loaded onto trucks or stacks of harvested crops require unloading. Gantry cranes take center stage here, effortlessly lifting and relocating materials with finesse. Their adaptability to outdoor environments and ability to handle substantial loads make them a reliable partner in storage yards, agricultural terminals, and distribution centers.

Single girder gantry crane

Single girder gantry crane specifications: Capacity: 1ton-20ton, Span Length: 8~30m, Working Class: A3, A4.

L leg single girder gantry crane

L types gantry crane specifications: Capacity 5ton -32ton, Span Length: 18~35m, Working Class: A5, A6.

Truss girder gantry crane

Truss gantry crane specifications: Capacity: 1 ton -50 ton, Span Length: 12~35m, Working Class: A5, A6.

Double girder gantry crane

Double girder gantry crane specifications: Capacity: 5 ton - 500 ton, Span Length: 12~35m, Working Class: A5, A6.

Semi gantry crane

Semi-gantry crane specifications: Capacity: 2 ton- 10 ton, Span Length: 8~20m, Working Class: A3, A4.

Portable gantry crane

Portable gantry crane specifications: Capacity:0.25 ton -10ton, Span length: 2~16m,Lifting height : 2~12m, Working class : A2.

Jib Cranes: Compact and Capable

In agriculture, sometimes precision and flexibility are required within limited spaces. This is where jib cranes shine. Characterized by their pivoting arm (jib), these cranes offer localized lifting solutions in areas where maneuverability is key.

- Design and Function: Jib cranes come in various configurations, including wall-mounted and freestanding versions. The jib can rotate, allowing the hoist to move loads horizontally and vertically within a limited radius. This compact design makes them ideal for tasks that demand precise positioning in tight spaces.

- Agricultural Applications: Jib cranes find their niche in diverse agricultural tasks. In livestock management, they aid in lifting and positioning equipment used for feeding and veterinary care. In greenhouses, they delicately transport potted plants and trays. Additionally, their compact design makes them invaluable in maintenance, as they lift heavy components for repairs without the need for excessive manual labor.

As the backbone of material handling in agriculture, bridge cranes, gantry cranes, and jib cranes offer diverse solutions tailored to the specific demands of each scenario. From processing plants to storage yards, their unique features and capabilities contribute to enhanced efficiency and seamless operations in the dynamic world of agriculture.

Pillar jib crane

Pillar jib crane specifications-Capacity:0.5 ton -10 ton, Arm length: 3-12m, Lifting height: 3-8m, Rotating : 180, 270, 360 ,Working class: A3.

Wall mounted jib crane

Wall mounted jib crane specifications-Capacity: 0.25 ton-2 ton, Arm length: 2-6m, Lifting height: 2-6m, Rotating : 180, Working class: A3.

Wall travelling jib crane

Wall-travelling jib crane specifications-Capacity: 0.25 ton-10 ton, Span: 3-10m, Lifting height: 3-8m, Rotating : 180,Working class: A3.

Portable jib crane

Portable jib crane specifications- Capacity: 0.08 ton,1 ton, Lifting Height: 1.5- 3m, Turning Radius: 2m, 3m, Rotation Angle: 360°, Working class: A3.

Requirements of overhead crane for agricultural industry

When considering the use of overhead cranes in the agricultural industry, there are several specific requirements that should be taken into account to ensure the cranes meet the unique needs of agricultural operations. These requirements vary depending on the type of agricultural activity and the specific tasks the overhead cranes will be used for. Here are some key agricultural industrial requirements for overhead cranes used in the field:

- 1. Load Capacity: Agricultural operations often involve handling heavy loads, such as bags of grain, bales of hay, or farm equipment. The overhead crane's load capacity should be chosen to accommodate the heaviest loads that will be encountered in the facility.

- 2. Durability and Weather Resistance: In some agricultural settings, overhead cranes may be used outdoors or in environments with varying weather conditions. The cranes should be designed to withstand exposure to elements like rain, wind, and dust. This may involve selecting materials and coatings that provide corrosion resistance.

- 3. Mobility and Flexibility: In certain agricultural operations, the need for mobility and flexibility is important. Gantry cranes or portable overhead cranes may be preferred in settings where the crane needs to be moved to different locations or adjusted to changing operational requirements.

- 4. Ease of Cleaning: Agricultural facilities often require thorough cleaning to maintain hygiene standards. Overhead cranes should be designed with features that facilitate easy cleaning and prevent the accumulation of dirt and debris.

- 5. Adaptability to Load Types: Agricultural facilities handle a diverse range of loads, from bulk materials like grains to equipment like tractors. The crane design should allow for the safe and efficient handling of different load types, sizes, and shapes.

- 6. Safety Features: Safety is paramount in any industrial setting. Overhead cranes should be equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and protect workers.

- 7. Environmental Considerations: In agriculture, certain products or materials being handled might be sensitive to contamination or damage. The crane's design should prevent any contamination during the handling process.

- 8. Clearance and Obstruction Avoidance: Agricultural facilities often have irregular layouts with equipment, storage areas, and other obstacles. The crane design should consider these obstacles and ensure proper clearance for smooth operation.

- 9. Control Systems: The control system of the overhead crane should be user-friendly and easy for operators to use. Depending on the complexity of the tasks, features like variable speed control and precision positioning may be important.

- 10. Maintenance and Serviceability: Agricultural operations are time-sensitive, and downtime due to crane maintenance can impact productivity. Overhead cranes should be designed for easy maintenance, and spare parts should be readily available.

- 11. Integration with Facility Layout: Overhead cranes should be integrated into the facility's layout and workflow to optimize material flow and operational efficiency. This might involve considering factors like crane placement, runway design, and access points.

- 12. Compliance with Regulations: Agricultural operations are subject to various safety and industry regulations. Overhead cranes should be designed and installed in compliance with these regulations to ensure legal and operational compliance.

Each agricultural operation is unique, so it's important to assess the specific requirements and challenges of the facility when selecting and designing overhead cranes. Consulting with crane manufacturers or experts who have experience in agricultural applications can help ensure that the chosen overhead crane meets all the necessary requirements for safe and efficient material handling in the agricultural industry.

What are the main functions of overhead cranes used in agriculture industry ?

The overhead cranes are used in the agriculture industry for various purposes, particularly in agricultural processing and storage facilities. Overhead cranes are heavy-duty machines designed to lift and move heavy loads horizontally within a defined area. Here are some common applications of overhead cranes in the agriculture industry:

- 1. Grain Handling: Overhead cranes are used in grain elevators and silos to load and unload grain from trucks and railcars. They can efficiently lift large quantities of grains and transfer them to storage bins or loading facilities.

- 2. Storage and Warehousing: In agricultural storage facilities, overhead cranes are used to move and stack bags of crops, such as grains, seeds, and fertilizers, to optimize space utilization and facilitate easy access to stored materials.

- 3. Livestock Handling: In large-scale livestock operations, overhead cranes can be used to move and position equipment for feeding, cleaning, and managing animals efficiently.

- 4. Greenhouse Operations: Overhead cranes can be employed in greenhouse settings to move potted plants, equipment, and materials within the confined space, aiding in plant care and maintenance.

- 5. Agri-Food Processing: Overhead cranes are used in food processing facilities to handle heavy equipment and loads during various stages of food processing, such as washing, sorting, and packaging.

- 6. Agricultural Machinery Maintenance: Overhead cranes are useful in agricultural machinery maintenance and repair workshops, allowing easy lifting and handling of heavy machinery components for servicing and repairs.

- 7. Irrigation System Installation: In large-scale irrigation projects, overhead cranes can be used to lift and place heavy pipes and irrigation equipment, aiding in the setup and maintenance of irrigation systems.

Overhead cranes offer several benefits in the agriculture industry, including increased efficiency, improved safety during heavy lifting operations, reduced labor requirements, and better organization and utilization of storage space. Their usage helps streamline agricultural operations, contributing to overall productivity and profitability.

kbk crane for agricultural machinery workshop

Typical applications of overhead cranes used in agriculture industry

Overhead cranes are used in the agriculture industry, particularly in certain agricultural operations that involve heavy lifting, movement of materials, and handling of large equipment. Overhead cranes provide an efficient and safe way to perform these tasks, increasing productivity and reducing manual labor. Some typical applications and main functions of overhead cranes in the agriculture industry include:

- 1. Handling Bulk Materials: Overhead cranes are used to lift and transport bulk materials like grains, fertilizers, and animal feed within agricultural facilities, such as grain elevators and feed mills. These cranes can move large quantities of materials quickly and precisely.

- 2. Loading and Unloading: Overhead cranes are employed for loading and unloading agricultural products, machinery, and equipment from trucks, wagons, or containers. This is especially useful in busy transportation hubs and storage facilities.

- 3. Maintaining and Servicing Equipment: Overhead cranes are used to lift heavy agricultural machinery and equipment, such as tractors or combine harvesters, for maintenance, repair, and inspection purposes.

- 4. Greenhouse Operations: Overhead cranes can be utilized in large-scale greenhouse operations to move heavy pots, containers, and equipment used for planting, harvesting, and maintenance.

- 5. Handling Livestock Feed: In some agricultural settings, overhead cranes are used to transport and distribute large quantities of livestock feed within barns or feeding areas.

- 6. Waste Handling: Overhead cranes can be employed to lift and move agricultural waste, such as crop residues or animal by-products, for disposal or recycling.

- Irrigation Infrastructure: In certain irrigation systems, overhead cranes are used to lift and place pipes, pumps, and other irrigation components.

Overhead crane for aspact of agriculture industry

In the agriculture industry, various procedures require different types of overhead cranes to effectively handle the diverse tasks involved. Here's a breakdown of the typical overhead cranes used in different procedures within the agriculture industry:

Crop Harvesting and Loading:

- Jib Cranes: Jib cranes are used for localized lifting and positioning tasks, such as loading harvested crops onto trucks or wagons for transportation. They are particularly useful in areas where space is limited.

- Typical Crane Type: Jib Crane

- Features: Jib cranes have a rotating arm (jib) that can be maneuvered to lift and position loads. They are compact, require minimal space, and offer 180-degree rotation.

- Benefits: Jib cranes are ideal for localized tasks, like loading harvested crops onto trucks, due to their flexibility and ease of use.

- Functions: Jib cranes assist in lifting and moving harvested crops from the field to transportation vehicles for distribution.

Processing and Packaging:

- Bridge Cranes: Bridge cranes are commonly used in processing facilities to move raw materials, intermediate products, and finished goods along production lines. They are well-suited for heavier loads and longer distances.

- Typical Crane Type: Bridge Crane

- Features: Bridge cranes consist of a bridge that spans the workspace, with a trolley and hoist system for vertical and horizontal movement.

- Benefits: Bridge cranes can cover larger areas, carry heavy loads, and offer precise positioning, making them suitable for material movement along processing lines.

- Functions: Bridge cranes are used to move raw materials, intermediate products, and finished goods within processing facilities.

Storage and Warehousing:

- Gantry Cranes: Gantry cranes are used for loading and unloading goods from storage areas or trucks in warehouses. They are particularly useful in outdoor storage yards or facilities without overhead structural support.

- Typical Crane Type: Gantry Crane

- Features: Gantry cranes have legs or supports on the ground and can be wheeled for mobility. They offer versatile movement in outdoor storage yards.

- Benefits: Gantry cranes are adaptable to various settings and are used for loading/unloading, moving goods within storage areas, and organizing stock.

- Functions: Gantry cranes assist in moving bulk agricultural products and equipment within warehouses or storage facilities.

Feed and Fertilizer Handling:

- Bridge Cranes: Bridge cranes can be used to move bulk materials like feed, grains, and fertilizers within storage facilities or processing areas.

- Typical Crane Type: Bridge Crane

- Features: Bridge cranes can be customized with attachments for lifting bulk materials like feed, grains, and fertilizers.

- Benefits: Bridge cranes can handle heavy loads and are suitable for transporting bulk materials to and from storage areas or processing machinery.

- Functions: Bridge cranes are used to load/unload feed and fertilizer materials and transport them within processing or storage areas.

Livestock Management:

- Jib Cranes: Jib cranes are useful for handling equipment and materials used in livestock management, such as feeding troughs or equipment for veterinary care.

- Typical Crane Type: Jib Crane

- Features: Jib cranes provide localized lifting and positioning. They can be equipped with various attachments for handling equipment used in livestock management.

- Benefits: Jib cranes offer flexibility for lifting and placing equipment needed for feeding, veterinary care, and other livestock-related tasks.

- Functions: Jib cranes assist in moving and positioning equipment used in livestock management operations.

Greenhouse Operations:

- Jib Cranes: Jib cranes can assist in moving potted plants, trays, and other materials within greenhouse facilities.

- Typical Crane Type: Jib Crane

- Features: Jib cranes offer precise positioning and can be installed in confined spaces.

- Benefits: Jib cranes are suitable for lifting and transporting potted plants, trays, and other materials within greenhouse facilities.

- Functions: Jib cranes help manage plant movement and positioning within greenhouses for care and maintenance.

Maintenance and Repair:

- Jib Cranes: Jib cranes are often employed for maintenance tasks, such as lifting and positioning heavy machinery components for repair.

- Typical Crane Type: Jib Crane

- Features: Jib cranes provide localized lifting for maintenance tasks.

- Benefits: Jib cranes assist in lifting heavy components and machinery parts for repair and maintenance without the need for extensive manual labor.

- Functions: Jib cranes are used to support maintenance activities on agricultural machinery and equipment.

Bulk Material Handling:

- Monorail Cranes: Monorail cranes can be useful for moving bulk materials along a fixed path, such as transporting harvested crops from one location to another.

- Typical Crane Type: Monorail Crane

- Features: Monorail cranes move along a single rail, making them suitable for linear material movement.

- Benefits: Monorail cranes efficiently transport bulk materials along a fixed path, such as transferring harvested crops to storage areas.

- Functions: Monorail cranes are used to transport bulk agricultural products along a designated path.

Loading and Unloading:

- Bridge Cranes or Gantry Cranes: These cranes are frequently used for loading and unloading trucks, wagons, and other transportation vehicles.

- Typical Crane Types: Bridge Crane or Gantry Crane

- Features: Bridge cranes and gantry cranes are capable of loading/unloading trucks, wagons, and other transportation vehicles.

- Benefits: These cranes provide efficient and safe loading/unloading of heavy agricultural products for distribution and transportation.

- Functions: Bridge cranes and gantry cranes are used for loading/unloading agricultural products onto/from transportation vehicles.

Specialized Tasks:

- Customized Cranes: Depending on specific agricultural operations, customized overhead crane configurations might be necessary. For example, cranes with specialized attachments could be used for tasks like lifting irrigation equipment or installing greenhouse infrastructure.

- Typical Crane Type: Customized Overhead Cranes

- Features: Customized overhead cranes can be tailored with specific attachments and features to meet unique agricultural tasks.

- Benefits: These cranes address specialized requirements and perform tasks such as lifting irrigation equipment or installing greenhouse infrastructure.

- Functions: Customized overhead cranes are designed for specific tasks that may not be covered by standard crane types.

Choosing the right type of overhead crane for each application ensures efficient and safe material handling within the agriculture industry. The features and benefits of each crane type align with the specific functions required in each procedure, contributing to optimized operations and increased productivity.

Overhead crane application in the related sectors to agriculture industry

The agriculture industry is closely connected to several related sectors that support, complement, and depend on its activities. These related sectors play a crucial role in ensuring the overall functionality, efficiency, and sustainability of the agriculture industry. Some of the key related sectors to the agriculture industry include:

Agribusiness and Food Processing:

Agribusiness encompasses a range of activities beyond farming, including food processing, packaging, distribution, and retail. Food processing transforms raw agricultural products into value-added goods like packaged foods, beverages, and other consumer products.

- Typical Crane Types: Bridge Cranes, Gantry Cranes

- Capacity: Medium to Heavy

- Features: Ability to handle bulk materials, precise positioning for packaging and processing lines.

- Functions: Material movement for processing, packaging, and distribution of food products.

- Typical Applications: Moving raw ingredients, packaged products, and equipment within food processing facilities.

- Tailored Features: Food-grade materials, sanitary design to meet hygiene standards, anti-corrosion coatings.

Agricultural Technology (AgTech):

This sector focuses on the development and application of technology to improve agricultural practices, efficiency, and sustainability. AgTech includes innovations like precision farming, automation, data analytics, and biotechnology.

- Typical Crane Types: Bridge Cranes, Gantry Cranes

- Capacity: Medium to Heavy

- Features: Integration with automation systems, data connectivity for real-time monitoring.

- Functions: Handling agricultural machinery/components during testing, assembly, and maintenance.

- Typical Applications: Research and development facilities for agricultural technology innovations.

- Tailored Features: Compatibility with IoT sensors, precision control for delicate equipment handling.

Livestock and Poultry:

Livestock production involves raising animals for meat, dairy, wool, and other products. Poultry farming, in particular, is a significant subsector, producing chicken, turkey, and eggs.

- Typical Crane Type: Jib Cranes

- Capacity: Light to Medium

- Features: Ease of use, compact design for confined spaces.

- Functions: Lifting and positioning equipment for feeding, veterinary care, and handling livestock.

- Typical Applications: Farms, stables, poultry houses.

- Tailored Features: Animal-friendly design, anti-corrosion coatings, attachments for feeders and waterers.

Horticulture and Floriculture:

Horticulture covers the cultivation of fruits, vegetables, nuts, herbs, and ornamental plants. Floriculture specifically deals with the cultivation of flowers and ornamental plants for decorative and aesthetic purposes.

- Typical Crane Type: Jib Cranes

- Capacity: Light to Medium

- Features: Precise positioning, compact design for greenhouses.

- Functions: Moving potted plants, trays, and supplies within greenhouse settings.

- Typical Applications: Greenhouses, nurseries.

- Tailored Features: Gentle handling attachments for delicate plants, corrosion-resistant materials.

Aquaculture and Fisheries:

Aquaculture focuses on farming aquatic organisms like fish, shellfish, and aquatic plants in controlled environments. Fisheries involve capturing wild fish and other aquatic species from oceans, rivers, and lakes.

- Typical Crane Type: Gantry Cranes

- Capacity: Medium to Heavy

- Features: Outdoor suitability, ability to handle heavy loads.

- Functions: Loading and unloading aquaculture equipment, handling harvested seafood.

- Typical Applications: Aquaculture farms, seafood processing facilities.

- Tailored Features: Water-resistant coatings, corrosion protection for marine environments.

Forestry and Wood Products:

Forestry includes the management and cultivation of forests for timber, wood products, and environmental conservation. It's closely linked to the sustainable management of natural resources.

- Typical Crane Type: Gantry Cranes

- Capacity: Heavy

- Features: Sturdy design, ability to handle large timber logs.

- Functions: Moving logs, loading/unloading wood products, equipment maintenance.

- Typical Applications: Sawmills, lumber yards, wood processing facilities.

- Tailored Features: Heavy-duty attachments, anti-corrosion coatings.

Agrochemicals and Fertilizers:

This sector involves the production and distribution of agricultural chemicals, pesticides, herbicides, and fertilizers that contribute to crop health, yield, and protection.

- Typical Crane Type: Bridge Cranes

- Capacity: Medium to Heavy

- Features: Safe lifting of bulk materials, protection against chemical exposure.

- Functions: Handling bags, drums, and containers of chemicals and fertilizers.

- Typical Applications: Agrochemical manufacturing and storage facilities.

- Tailored Features: Corrosion-resistant materials, chemical-resistant coatings.

Rural Development and Land Management:

Rural development initiatives focus on improving the socio-economic conditions of rural areas. Land management ensures the sustainable use of land resources for agriculture and other purposes.

- Typical Crane Type: Jib Cranes

- Capacity: Light to Medium

- Features: Compact design, versatility for various tasks.

- Functions: Handling equipment for land maintenance, rural infrastructure development.

- Typical Applications: Rural development projects, land management initiatives.

- Tailored Features: Attachments for different tasks, weather-resistant finishes.

Agricultural Finance and Banking:

Financial institutions provide loans, credit, and financial services to farmers and agribusinesses for investments in production, equipment, and infrastructure.

- Typical Crane Type: Jib Cranes

- Capacity: Light

- Features: Compact and easy to operate.

- Functions: Moving documents, organizing paperwork, equipment maintenance.

- Typical Applications: Banking and financial institutions serving the agriculture sector.

- Tailored Features: Security features, space-saving design.

Agricultural Research and Education:

Research institutions, universities, and organizations contribute to agricultural advancements by developing new crop varieties, sustainable practices, and agricultural education programs.

- Typical Crane Type: Jib Cranes, Bridge Cranes

- Capacity: Light to Medium

- Features: Precision positioning, ease of use.

- Functions: Handling equipment for experiments, agricultural education demonstrations.

- Typical Applications: Agricultural research institutions, educational facilities.

- Tailored Features: Versatility for various research needs, integration with educational tools.

Food Distribution and Retail:

This sector involves the distribution and retailing of agricultural products to consumers. It includes supermarkets, grocery stores, farmers' markets, and online food delivery platforms.

- Typical Crane Type: Bridge Cranes

- Capacity: Medium to Heavy

- Features: Efficient loading/unloading, precise positioning for storage.

- Functions: Handling goods in distribution centers, stock management.

- Typical Applications: Warehouses, distribution hubs, retail centers.

- Tailored Features: Integration with inventory management systems, ease of operation.

Environmental Conservation and Sustainability:

This sector focuses on promoting sustainable agriculture practices that minimize negative environmental impacts and ensure long-term food security.

- Typical Crane Type: Gantry Cranes

- Capacity: Medium to Heavy

- Features: Sturdy design, compatibility with eco-friendly practices.

- Functions: Handling equipment for conservation projects, waste management.

- Typical Applications: Environmental agencies, sustainability initiatives.

- Tailored Features: Attachments for waste separation and recycling, sustainable materials.

These related sectors work in tandem with the agriculture industry to ensure a stable supply of food, fiber, and other agricultural products, while also addressing economic, social, and environmental challenges. The interconnected nature of these sectors underscores the complexity of modern agricultural systems.

Considerations for Buyers

Identifying Specific Needs: Tailoring to Your Tasks

Before diving into the world of electric overhead cranes, it's crucial to take a step back and analyze your agricultural operations. What are your material handling needs? Are you dealing with delicate plants, heavy machinery, or both? Identifying your specific needs is the compass that will guide your crane selection journey.

Load Capacity and Size: Right-Sizing Your Crane

Once you have a clear understanding of your tasks, it's time to assess the loads you'll be handling. Different agricultural tasks come with varying load capacities and sizes. Whether you're lifting bags of feed or transporting machinery, it's essential to determine the appropriate load capacity and crane size. This ensures that your chosen crane can handle your tasks with ease and efficiency.

Facility Layout and Space: Crafting a Seamless Setup

Even the most advanced crane can't work its magic if it doesn't fit within your facility's layout. Consider the available space and layout of your agricultural setting. Will you be working in a compact greenhouse or a vast storage yard? Evaluating the available space helps you choose a crane that seamlessly integrates into your environment, optimizing both functionality and efficiency.

Environmental Conditions: Confronting the Elements

Agricultural operations often expose machinery to various environmental conditions. From scorching sun to relentless rain, your crane will need to stand up to the elements. Additionally, corrosive environments, such as those near livestock or chemical storage, require specialized considerations. Ensuring that your crane is designed to withstand these conditions guarantees longevity and reliable performance.

Safety Regulations and Compliance: Safety First, Always

In the dynamic world of agriculture, safety is paramount. Adhering to safety standards and regulations ensures the well-being of workers, livestock, and equipment. As you explore electric overhead cranes, keep in mind the importance of choosing a crane that complies with industry safety regulations. A safe crane is not just an asset; it's a lifeline.

Integration with Technology: A Glimpse into the Future

In a world driven by technology, the ability to integrate your crane with automation and IoT systems can revolutionize your operations. Imagine remotely controlling your crane or receiving real-time data on load status. As you explore electric overhead cranes, consider their compatibility with these technological advancements, paving the way for enhanced efficiency and data-driven decision-making.

Customization and Tailored Features: Making It Your Own

Electric overhead cranes are not one-size-fits-all solutions. They can be tailored to suit your specific needs and tasks. As you delve into customization options, consider the following:

Attachment Options: Enhancing Functionality

Attachments can transform a standard crane into a specialized tool. Whether it's a lifting magnet for handling metal or a specialized hook for delicate materials, exploring attachment options can enhance your crane's functionality, making it a perfect fit for your agricultural tasks.

Materials and Coatings: Resilience and Hygiene

The materials and coatings used in your crane's construction play a significant role in its durability and hygiene compliance. For agricultural settings, where exposure to elements and contaminants is common, opting for corrosion-resistant materials and hygiene-friendly coatings ensures a longer lifespan and adherence to cleanliness standards.

Remote Control and Automation: Efficiency Redefined

The ability to remotely control your crane or automate its movements can revolutionize your operations. From reducing the need for manual labor to enhancing precision, remote control and automation options offer efficiency gains that translate into time and cost savings.

Customization and tailored features are the cornerstones of optimizing your electric overhead crane for the unique demands of the agriculture industry. Whether it's through specialized attachments that elevate functionality, the right choice of materials and coatings for durability and compliance, or the integration of remote control, automation, and IoT systems for enhanced efficiency, customization empowers you to create a crane that's not just a piece of equipment, but a precision tool that revolutionizes your agricultural operations. By leveraging the power of customization, you're investing in a crane that doesn't just meet your needs – it exceeds them, enabling you to reach new heights in agricultural efficiency and effectiveness.

Choosing a Reliable Manufacturer

Selecting the right manufacturer is a pivotal step in the journey toward acquiring the perfect electric overhead crane for your agricultural operations. In this section, we'll guide you through the essential factors to consider when choosing a manufacturer that aligns with your needs and aspirations.

Reputation and Experience: Building on a Strong Foundation

Reputation and experience are the cornerstones of a reliable manufacturer. Before making a decision, delve into the manufacturer's history and track record. Look for indicators of quality, reliability, and consistency in their products. A manufacturer with a proven track record is more likely to provide you with a crane that meets and exceeds your expectations.

Customization and Consultation: Your Partner in Progress

A manufacturer that understands the significance of customization is a manufacturer worth considering. The ability to tailor your crane to your precise needs is a testament to their commitment to your success. Look for manufacturers that offer expert consultation to guide you through the customization process. Their insights and expertise can help you optimize your crane for maximum efficiency and effectiveness.

Customer Support and Maintenance: Beyond the Sale

The relationship with your manufacturer doesn't end with the sale; it's an ongoing partnership. Prioritize manufacturers that offer comprehensive customer support and maintenance services. This includes training for your operators to ensure safe and efficient crane operation. Regular maintenance and service are vital to keeping your crane in peak condition, minimizing downtime, and prolonging its lifespan.

Choosing a reliable manufacturer for your electric overhead crane is a decision that has far-reaching implications for your agricultural operations. By selecting a manufacturer with a strong reputation, extensive experience, and a commitment to customization and consultation, you're investing in a partnership that fosters growth and success. Moreover, manufacturers that offer robust customer support and maintenance services ensure that your crane remains a valuable asset, delivering results long after the initial purchase. As you embark on this journey, remember that the right manufacturer isn't just selling you a crane – they're equipping you with the tools to elevate your agricultural endeavors to new heights.

freestanding bridge crane for agricultural machinery parts and components assembly workshop

freestanding bridge crane for agricultural machinery parts and components assembly workshop

Making the Purchase

The moment of acquiring your electric overhead crane marks the culmination of careful planning and research. In this section, we'll guide you through the crucial steps to ensure a successful purchase, installation, and long-term utilization of your crane.

Request for Proposal (RFP): Communicating Your Vision

Crafting a well-structured Request for Proposal (RFP) is the foundation of effective communication with potential manufacturers. Your RFP should clearly outline your specific requirements, including load capacities, features, customization needs, and any special considerations. Providing a detailed RFP helps manufacturers understand your vision and empowers them to offer tailored solutions that align with your agricultural operations.

Budget Considerations: Balancing Costs and Investment

Assessing costs and budgeting for your crane's purchase and installation is a critical step. Beyond the initial purchase price, consider factors such as installation, customization, and potential future maintenance costs. While it's important to optimize your investment, remember that quality and reliability often correlate with cost. Finding the right balance ensures you acquire a crane that delivers long-term value.

Installation and Training: Building the Foundation

The successful installation of your electric overhead crane sets the stage for its optimal performance. Ensure that installation is carried out by qualified professionals who understand the intricacies of crane setup. Once installed, prioritize operator training. Proper training empowers your team to use the crane safely and efficiently, minimizing the risk of accidents and maximizing operational success.

Maintenance and After-Sales Service: Sustaining Performance

The journey doesn't end with installation; it's an ongoing process that requires consistent care. Establishing a maintenance schedule is paramount to keeping your crane in peak condition. Regular inspections and timely maintenance prolong its lifespan and prevent unexpected downtime. Additionally, understand the after-sales service offered by the manufacturer. A reliable manufacturer will provide swift and efficient support when issues arise, ensuring uninterrupted crane performance.

The process of purchasing, installing, and utilizing your electric overhead crane is a multifaceted journey that demands meticulous attention to detail. By crafting a comprehensive RFP, assessing budget considerations, ensuring proper installation and training, and establishing a robust maintenance schedule, you're setting the stage for a successful partnership with your crane. As your crane becomes an integral part of your agricultural operations, remember that your commitment to quality, safety, and ongoing care will translate into enhanced efficiency, longevity, and tangible results.

Conclusion: Harnessing the Power of Electric Overhead Cranes in Agriculture

As we conclude this comprehensive guide, let's take a moment to recap the remarkable benefits that electric overhead cranes bring to the agriculture industry. These cutting-edge cranes have the potential to reshape the way agricultural operations are conducted, enhancing efficiency, safety, and sustainability.

Electric overhead cranes stand as beacons of energy efficiency, reducing operational costs and minimizing environmental impact. Their precision and control redefine material handling, enabling delicate tasks to be executed with unmatched accuracy. Safety features like overload protection and emergency stops ensure the well-being of workers and livestock alike. The versatility of these cranes allows them to adapt to a myriad of agricultural tasks, from heavy-duty lifting to gentle plant handling. Moreover, their reduced noise levels and zero emissions contribute to a quieter, cleaner work environment that aligns with eco-friendly practices.

For manufacturers, this guide is a call to action. Showcase your products' features and capabilities, highlighting how your electric overhead cranes can transform the agricultural landscape. Your innovation has the power to revolutionize the way farms and agribusinesses operate, and your commitment to quality and customization is the key to unlocking the full potential of these cranes.

For buyers, we encourage you to embark on this journey with confidence and clarity. Armed with the insights from this guide, you're well-equipped to make informed decisions that resonate with your agricultural operations. Remember, your choice of electric overhead crane isn't just an investment – it's an investment in the efficiency, safety, and growth of your agricultural endeavors. By choosing the right crane, customized to your needs, you're poised to elevate your operations to new heights of excellence.

In the dynamic realm of agriculture, where every innovation counts, electric overhead cranes stand as a testament to progress. They're not just machines; they're partners in your journey toward agricultural success. As the fields transform and the landscape evolves, remember that your decisions today shape the agriculture of tomorrow. So, embrace the power of electric overhead cranes, showcase their potential, and embrace a future where agriculture thrives like never before.

This comprehensive guide outline serves as a starting point for creating a detailed guide that both manufacturers and buyers in the agriculture industry can benefit from. It covers essential aspects of electric overhead cranes, their benefits, considerations, customization options, and the purchasing process.