How Bridge Span Impacts Single vs Double Girder Overhead Cranes

Span plays a key role in overhead crane design. Learn when a 10 ton eot crane should use single or double girders based on span, capacity & operation.

Category: Featured

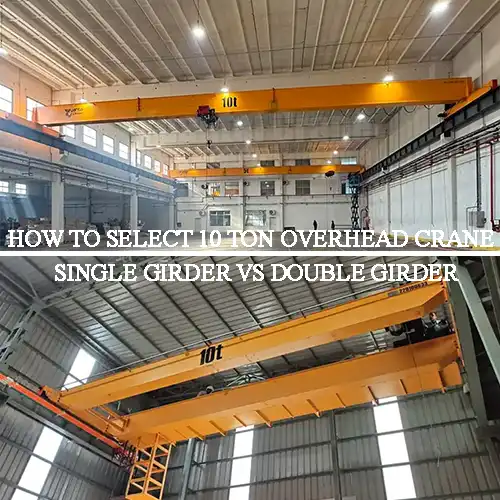

Your Trusted 10 Ton Overhead Crane Manufacturer & Supplier

How Bridge Span Affects Overhead Crane Design

— Single Girder vs. Double Girder for 10 Ton Overhead Crane

Introduction

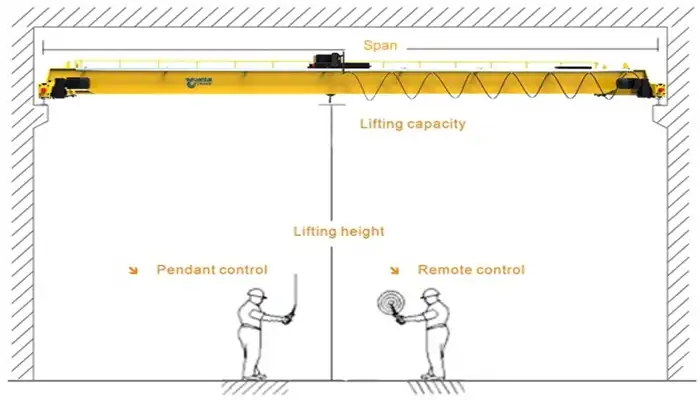

When it comes to overhead cranes, one of the most important factors to consider is the bridge span. Simply put, the bridge span is the distance between the two runway beams that the crane travels on. This span directly affects how the crane is designed and how well it performs in your workshop or factory.

Why does span matter so much? Well, the length of the bridge affects the size and strength of the crane's main girder, which supports the load. The longer the span, the stronger and stiffer the girder needs to be. If the girder isn't designed properly, the crane could bend or sway, causing safety risks and reducing its lifespan.

In this section, we'll focus on how the bridge span impacts the design of a 10 ton overhead crane — one of the most common capacities for small to medium industrial applications. Understanding this will help you choose the right crane type, whether single girder or double girder, based on the span you need.

Key points to keep in mind about bridge span:

- Bridge span is the clear distance between runway beams where the crane moves.

- Longer spans require stronger and more rigid girders to prevent bending or excessive deflection.

- The crane's overall design, including girder type, depends heavily on the span.

- Getting the span right can save you money on both the crane itself and ongoing maintenance.

- For a 10 ton overhead crane, the span range often determines whether a single girder or double girder crane is best suited.

By keeping these practical factors in mind, you'll be better equipped to pick a crane that fits your workshop layout and lifting needs without overspending or compromising safety.

What is Bridge Span?

The bridge span is a fundamental concept in overhead crane design, but it's often misunderstood or overlooked by buyers. Simply put, the bridge span is the clear distance between the two runway beams or rails on which the crane's main girder travels. Think of it like the width of a river the crane has to cross—the longer that distance, the stronger and more carefully engineered the "bridge" (girder) needs to be.

Definition of Bridge Span:

- The distance measured from the inner faces of the two runway rails or beams.

- It represents the full width the crane's main girder must cover to move across the workspace.

- Usually expressed in meters or feet, depending on regional standards.

Typical Spans in Different Settings:

- Small workshops: Typically, spans range from 5 to 15 meters (16 to 50 feet). These are usually compact spaces where a single girder crane is common.

- Medium factories and warehouses: Spans can range from 15 to 30 meters (50 to 100 feet). This often pushes the limits of single girder designs and may require double girder cranes for extra strength.

- Large industrial plants: Spans can exceed 30 meters (over 100 feet), demanding robust double girder cranes or even specialized designs to maintain safety and rigidity.

The span you need will largely depend on the size of your building and the area you want the crane to cover.

Why Bridge Span Matters for Crane Structure:

- The longer the span, the more bending force the main girder experiences.

- Increased span means the girder must be stronger and stiffer to prevent excessive deflection (bending under load), which can cause problems like poor crane operation, damage, and safety hazards.

- Larger spans generally lead to heavier girders and more expensive cranes, as extra material and stronger engineering are required.

- The span affects not only the girder but also the selection of wheels, runway beams, and the entire crane support system.

Your crane's bridge span is not just a measurement — it's a key factor that drives how the crane is built and how much it will cost. Getting this right upfront helps avoid expensive mistakes, like buying an undersized crane that won't perform well or an oversized crane that costs too much.

For a 10 ton overhead crane, understanding the typical span you need will guide you toward the right design, ensuring safe, reliable lifting with the best value.

Impact of Bridge Span on Crane Design

The bridge span plays a big role in shaping how an overhead crane is designed, especially when it comes to the main girder—the backbone of the crane. The longer the span, the more challenges designers face to keep the crane safe, strong, and efficient.

Influence on Main Girder Size and Strength

- Longer spans mean the main girder has to carry the load across a wider gap without bending too much.

- To handle this, the girder's cross-section often needs to be larger and made from thicker steel plates or heavier beams.

- For example, a 10 ton crane with a 10-meter span will have a slimmer girder than one with a 25-meter span, which requires a much beefier structure to stay safe.

- The girder material and welding quality must meet higher standards for longer spans to avoid cracks or failures.

Effect on Deflection and Rigidity

- Deflection is the amount the girder bends under the weight of the load. Too much deflection affects crane operation and can be dangerous.

- Longer spans naturally increase deflection because there's more distance for the girder to bend.

- To keep deflection within safe limits, designers must increase the girder's stiffness by using stronger materials or changing the design (e.g., switching from single to double girder).

- Proper rigidity ensures smooth trolley movement, accurate load positioning, and longer crane life.

Consequences for Crane Weight and Structural Complexity

- As girder size increases, so does the overall crane weight. A heavier crane means more load on runway beams and building structure.

- This can require upgrades to the runway, foundation, or even the building itself, increasing overall project complexity.

- Double girder cranes often come into play for longer spans because they distribute the load better and offer more stability, but they are heavier and more complex to manufacture and install.

- The added structural complexity can mean more time and cost during manufacturing, delivery, and installation.

Influence on Installation and Maintenance Costs

- Larger, heavier girders need special equipment and more labor for installation, which raises initial project costs.

- Longer spans and heavier cranes also mean more wear and tear on runway rails and wheels, increasing maintenance needs over time.

- Choosing the right girder design based on span can reduce unexpected downtime and save money on repairs and inspections.

- A well-matched crane design improves operational reliability and reduces long-term expenses.

In short, the bridge span directly shapes the girder design, overall crane weight, and the complexity of both installation and maintenance. Getting this balance right—especially for a 10 ton overhead crane—means safer operation, less hassle, and better value for your investment.

Single Girder Overhead Crane Basics

A single girder overhead crane is one of the most popular and cost-effective crane types, especially for light to medium lifting tasks. As the name suggests, it has only one main girder that spans across the runway beams, supporting the hoist and trolley.

Description and Main Components

- Main Girder: A single steel beam that runs across the workspace, carrying the hoist and trolley.

- End Trucks: Located at both ends of the girder, these wheels run along the runway rails to move the crane back and forth.

- Hoist and Trolley: Mounted directly on the girder, the hoist lifts and lowers the load while the trolley moves it horizontally along the girder.

- Runway Beams: Parallel beams installed on the building structure or columns that guide the crane's movement across the facility.

Advantages of Single Girder Cranes

- Lighter weight: Because they use only one girder, these cranes are lighter compared to double girder cranes of the same capacity.

- Lower cost: Fewer materials and simpler design make single girder cranes more affordable upfront.

- Easier installation: The lighter and simpler structure means installation is faster and requires less heavy equipment.

- Lower maintenance: With fewer components, maintenance tends to be simpler and less expensive.

Typical Span Range for Single Girder Cranes

- Single girder cranes usually perform well with spans up to about 20 meters (65 feet).

- For shorter spans—say 5 to 15 meters—they are often the most economical and practical choice.

- Beyond this range, the girder may need to be excessively large or reinforced to handle deflection, reducing the cost advantage.

Limitations in Terms of Capacity and Span

- Weight capacity: Single girder cranes typically handle capacities up to around 10 to 16 tons, but 10 tons is usually the practical upper limit for most standard single girder designs.

- Span limits: Longer spans above 20 meters put more stress on a single girder, causing increased bending and vibration. This can affect safety and crane lifespan.

- Lifting height: The hook height is limited because the hoist runs on top of the single girder, taking up some of the lifting space.

- Less rigidity: Compared to double girder cranes, single girder cranes have less structural stiffness, which may impact precision in heavier or frequent lifting applications.

For a 10 ton overhead crane with a relatively short to medium span, a single girder design often hits the sweet spot between cost, ease of use, and performance—provided the span isn't too long and the lifting height fits the application.

Double Girder Overhead Crane Basics

A double girder overhead crane features two main girders running parallel across the runway beams. This design is common in heavier lifting applications and where longer spans are needed. The hoist travels on a trolley mounted between the two girders, allowing for higher lifting heights and stronger structural support.

Description and Main Components

- Two Main Girders: Two parallel steel beams that provide a robust structure to carry heavier loads over longer distances.

- End Trucks: Positioned at both ends of each girder, these wheels run along the runway rails, moving the entire crane bridge.

- Trolley and Hoist: The trolley runs between the two girders, carrying the hoist which lifts and lowers the load.

- Runway Beams: Supporting rails attached to the building or columns that guide the crane along the workspace.

Advantages of Double Girder Cranes

- Higher capacity: Able to safely handle heavier loads—well beyond 10 tons if needed. For a 10 ton crane, double girders add extra safety and rigidity.

- Longer spans: Designed to cover longer distances, often from 20 meters up to 35 meters or more without excessive girder deflection.

- Better rigidity: The dual girder design resists bending and sway, providing stable and precise load handling.

- Higher lifting height: Because the hoist runs between the girders, double girder cranes allow for greater hook travel, maximizing vertical lifting space.

Typical Span Range for Double Girder Cranes

- Well suited for spans above 20 meters (65 feet) and can go up to 35 meters (115 feet) or more, depending on design and application.

- For a 10 ton capacity, double girder cranes become the preferred choice when the span exceeds about 20 meters to maintain safety and performance.

Increased Cost and Installation Complexity

- Higher initial cost: Double girder cranes require more steel and materials, which increases purchase price.

- More complex installation: Heavier components need cranes or specialized equipment to install, extending installation time and cost.

- Increased building requirements: The heavier crane means runway beams, columns, and foundations often need to be stronger or reinforced.

- More maintenance: Two girders, additional wheels, and a more complex trolley system can lead to higher maintenance needs.

In summary, while double girder cranes cost more upfront and are more complex to install, they provide unmatched strength, longer span coverage, and higher lifting heights. For a 10 ton overhead crane with a span over 20 meters, a double girder setup is often the smartest choice to ensure safety, reliability, and long-term value.

Choosing Between Single Girder and Double Girder for a 10 Ton Overhead Crane

Picking the right type of crane girder for a 10 ton overhead crane mainly comes down to the bridge span you need, but several other factors should also be considered. Here's a straightforward guide to help you decide.

Span Thresholds for 10 Ton Capacity

- Span less than about 20 meters:

For spans under 20 meters (around 65 feet), a single girder crane usually does the job well. It offers a good balance between cost and performance without being too heavy or complex. - Span greater than about 20 meters:

Once your span crosses the 20-meter mark, a double girder crane becomes the safer and more reliable choice. The extra girder provides the strength and rigidity needed to handle the longer span without excessive bending or vibration.

Consideration of Duty Cycle and Usage Frequency

- If your crane will be used frequently or for heavy-duty cycles, double girder cranes offer better durability and smoother operation.

- For lighter, occasional use, especially with shorter spans, a single girder crane can be more cost-effective and easier to maintain.

Influence of Lifting Height and Crane Type

- Lifting Height (Hook Height):

Double girder cranes allow for higher hook travel because the hoist sits between the girders, maximizing lifting height. If you need to lift loads to higher elevations, double girder is often better.

Crane Type:

- Top Running Cranes: Usually double girder; they run on runway rails on top of the building structure, supporting heavier loads and longer spans.

- Under Running Cranes (Underslung): More common as single girder cranes; they hang below the runway beams and work well for shorter spans and lighter loads.

Other Factors to Keep in Mind

- Building Height: Taller buildings with sufficient overhead clearance may allow for double girder cranes, while low-clearance buildings often require single girder cranes due to height limitations.

- Power Supply: The availability and type of power supply can influence crane type, especially if you plan for electrification options or automation in the future.

- Installation Conditions: Tight spaces or difficult access areas might favor lighter single girder cranes for easier installation. Heavier double girder cranes may need more preparation and equipment for installation.

For a 10 ton overhead crane, if your span is under 20 meters and the lifting height is moderate, a single girder crane is usually the practical and budget-friendly choice. If the span stretches beyond 20 meters or if you require more lifting height and heavy-duty use, a double girder crane will deliver the strength and safety you need, even if it costs more upfront. Always consider your specific operational demands and site conditions to pick the best fit.

Practical Examples and Case Studies

Sometimes, seeing real-world examples helps make these concepts clearer. Let's look at two typical cases for 10 ton overhead cranes and how the bridge span influences the choice between single and double girder designs.

Example 1: 10 Ton Single Girder Crane for 15m Span Workshop

- Situation: A small manufacturing workshop with a clear span of 15 meters and moderate lifting needs.

- Design Choice: Single girder crane selected due to the relatively short span and 10 ton capacity.

Benefits:

- Lower upfront cost and quicker installation.

- Lighter crane structure, which fits well with existing runway beams.

- Suitable for occasional to moderate lifting cycles without over-engineering.

Limitations:

- Hook height slightly limited due to hoist placement on top of the girder.

- Less rigidity compared to double girder cranes but sufficient for this span.

Example 2: 10 Ton Double Girder Crane for 25m Span Factory

- Situation: A medium-sized factory requiring crane coverage over a 25-meter span with regular lifting operations.

- Design Choice: Double girder crane recommended for safety and performance reasons.

Benefits:

- Greater structural strength and reduced deflection over the longer span.

- Higher hook travel, allowing for taller loads or stacking.

- Better suited for frequent and heavy-duty lifting cycles.

Considerations:

- Higher initial cost and more complex installation.

- Requires stronger runway beams and possibly building reinforcement.

- Check more types of 10 ton overhead crane designs for your reference.

Cost and Performance Comparison

| Aspect | Single Girder (15m Span) | Double Girder (25m Span) |

|---|---|---|

| Initial Cost | Lower | Higher |

| Installation Time | Faster | Longer, more complex |

| Maintenance | Simpler, less expensive | More components to maintain |

| Rigidity & Stability | Adequate for shorter spans | Superior, handles longer spans easily |

| Lifting Height | Limited by hoist on top of girder | Higher due to hoist between girders |

| Structural Weight | Lighter | Heavier, impacts building structure |

Summary and Recommendations

Understanding how bridge span affects girder choice is crucial when selecting a 10 ton overhead crane. The span is often the deciding factor between single and double girder designs.

Key Takeaways for Buyers and Engineers:

- Spans under about 20 meters usually favor single girder cranes for their cost-effectiveness and simplicity.

- Spans over 20 meters almost always require double girder cranes for safety, rigidity, and performance.

- Consider the lifting height and usage frequency as they impact crane design beyond just span and capacity.

- Don't overlook building constraints like ceiling height and runway beam strength, which may limit your options.

- Balance upfront cost with long-term performance and maintenance needs.

When choosing your 10 ton overhead crane, don't just look at the price tag. Think about your current and future needs, the span you have to cover, and how often you'll use the crane. A well-matched crane—whether single or double girder—will give you safer operation, smoother lifting, and fewer headaches down the road. Taking the time to get these details right pays off in the long run.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch