Overhead Cranes for Indoor Facilities – Buyer’s Guide

Check how to choose the right indoor overhead crane for workshops, warehouses, and industrial buildings. Capacity, type, safety, and customization explained.

Category: Featured

Your Trusted Indoor Overhead Crane Manufacturer & Supplier

Overhead Cranes for Sale for Indoor Facilities

A Complete Buyer's Guide for Workshops, Warehouses, and Industrial Buildings

Most Important Takeaway (Read This First)

Choosing the right overhead crane for indoor use is not just about lifting capacity or price. It requires matching the indoor crane types, duty class, building structure, hoist configuration, and safety requirements to the actual working conditions of your workshop, warehouse, or industrial facility. A well-specified indoor overhead crane improves productivity, ensures compliance, reduces long-term operating costs, and avoids costly retrofits or downtime.

Key Takeaways – What This Guide Helps You Understand

- Which overhead crane types are best suited for indoor workshops and warehouses

- How to define lifting capacity, span, lifting height, and duty class correctly

- The difference between single girder, double girder, and underhung overhead cranes

- How building structure and runway design affect crane selection

- What to consider when choosing an electric hoist for indoor cranes

- Which safety features and certifications are essential for indoor operations

- What factors influence overhead crane prices and total cost of ownership (TCO)

- How to evaluate a reliable overhead crane supplier for indoor projects

Why Overhead Cranes Are Essential for Indoor Facilities

Indoor overhead cranes provide crucial benefits for space utilization, safety, and efficiency in workshops and warehouses. They optimize floor space, reduce lifting risks, and improve operational efficiency.

Make use of space that would otherwise be wasted

In most workshops and warehouses, floor space is the first constraint. Machines, storage racks, and workstations fill the ground level quickly. An indoor overhead crane solves this by lifting and moving loads through the open space above the floor, where nothing else can operate.

- Frees up valuable floor area

- Keeps aisles clear for people and equipment

- Allows direct load movement without detours

For facilities with limited space, this alone often justifies the investment.

Reduce risk in daily lifting operations

Indoor facilities usually handle the same loads again and again. Dies, molds, components, and heavy pallets are moved every shift. Repeating these lifts with forklifts or manual methods increases accident risk and operator fatigue.

An indoor material handling crane is built for repeat lifting:

- Smooth, controlled lifting and lowering

- Stable horizontal travel along a fixed path

- Safety functions such as overload and limit protection

The result is more consistent handling and fewer unexpected incidents.

Fit the crane to the building, not the other way around

Indoor overhead cranes are selected around the building's structure. Span, lifting height, runway position, and headroom must align with columns, beams, and roof limits.

A well-designed warehouse overhead crane system:

- Works within existing structures

- Supports retrofit projects without major construction

- Makes full use of available building height

This makes overhead cranes practical even in older or space-restricted facilities.

Improve handling efficiency where precision matters

Forklifts offer flexibility, but they are inefficient for straight-line moves, positioning, and assembly work. Each lift requires approach, alignment, travel, and repositioning.

Overhead cranes simplify the task:

- Lift vertically

- Travel across the bay

- Lower directly into position

This saves time in workshops and reduces bottlenecks in warehouses where placement accuracy matters.

Designed for indoor working environments

Indoor cranes must operate close to people, machinery, and production lines. For this reason, their design focuses on control and comfort rather than raw speed.

Typical industrial indoor crane features include:

- Low-noise drives and smooth motion

- Precise pendant or remote control

- Compact layouts that avoid collisions with lighting and ducts

These details support daily operation, not just technical performance.

A permanent part of the facility workflow

An overhead crane is not a temporary tool. Once installed, it shapes how materials move and how layouts evolve.

As a workshop lifting solution, an indoor overhead crane:

- Reduces handling time over years of use

- Improves safety consistency

- Supports future production changes without rework

This is why overhead cranes are considered essential infrastructure in indoor facilities, not optional equipment.

Common Indoor Applications for Overhead Cranes

Indoor overhead cranes are highly versatile and used wherever heavy or repetitive lifting is required. They save floor space, improve workflow, and reduce handling risks. Below is a breakdown of the most common applications:

Manufacturing Workshops

Workshops often need precise and frequent lifting for production or maintenance tasks. An overhead crane for workshop use makes operations safer and faster.

Typical applications include:

- Machining and CNC workshops for moving heavy machine parts

- Fabrication and assembly lines, especially for steel structures or mechanical assemblies

- Handling molds, dies, and tooling in injection molding or metal stamping shops

- Maintenance and equipment positioning to replace or repair heavy components

Practical tip: A single girder crane is often enough for light to medium loads, while double girder cranes handle heavier tooling and assembly tasks.

Warehouses and Storage Buildings

In warehouses, the goal is efficient storage and retrieval of heavy items. Overhead cranes reduce dependency on forklifts and make internal logistics smoother.

Key uses include:

- Lifting heavy pallets, machinery, or equipment

- Storing spare parts and industrial components safely

- Internal transfer of bulky or awkward loads across aisles or bays

- Reducing forklift traffic and congestion to prevent accidents

Other Indoor Industrial Facilities

Beyond workshops and warehouses, overhead cranes are essential in specialized indoor industrial environments.

Common examples:

- Power plants and utility buildings for equipment installation and maintenance

- Automotive manufacturing workshops for engine blocks, transmissions, and assembly line components

- Plastic, rubber, and light steel plants for handling molds, raw material hoppers, or fabricated parts

Types of Overhead Cranes for Indoor Use

Choosing the right overhead crane type is critical for indoor facilities. The decision affects lifting capacity, building compatibility, workflow efficiency, and long-term maintenance. Below are the main types commonly used indoors:

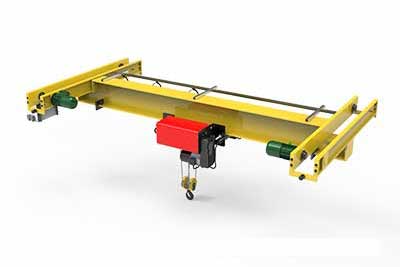

Single Girder Overhead Cranes

Single girder cranes are cost-effective and simple. They are ideal for light to medium-duty lifting in workshops and smaller warehouses.

Key features:

- Capacity: 1–20 tons

- Lighter structure and smaller wheel loads, which reduces stress on the building

- Compact design suitable for low headroom spaces

Best for:

- Budget-conscious buyers

- Facilities with lower duty cycles

- Workshops or warehouses where building height is limited

Single girder cranes are often paired with wire rope or chain hoists and are straightforward to install and maintain.

Double Girder Overhead Cranes

Double girder cranes are designed for heavier loads and higher utilization. They offer more stability and lifting height than single girder cranes.

Key features:

- Capacity: 5–100+ tons (commonly 10–20 tons for indoor applications)

- Higher lifting height and wider spans

- Supports precision lifting and future expansion needs

Best for:

- Heavy-duty indoor workshops

- High-utilization warehouses

- Facilities where long-term flexibility and heavier lifting are required

Double girder cranes are usually equipped with European-style wire rope hoists for smoother operation and longer service life.

Underhung (Underrunning) Overhead Cranes

Underhung cranes are suspended from the bottom flange of the runway beam, freeing up floor space. They are ideal for light-duty applications where building columns or low ceilings limit options.

Key features:

- Runs on the underside of runway beams

- Lower capacity compared to top-running cranes

- Requires sufficient roof or ceiling load capacity

Best for:

- Light-duty indoor facilities

- Areas where floor space is limited

- Workshops that cannot accommodate top-running crane structures

Practical takeaway: Selecting the right crane type ensures the system fits your building structure, load requirements, and workflow, avoiding over-specification or wasted investment.

Key Technical Parameters Buyers Must Define

Before buying an indoor overhead crane, you need to clarify the main technical parameters. The right choices ensure the crane works safely, handles the intended load efficiently, and lasts for years.

Lifting Capacity

Lifting capacity is the most important factor. For indoor use, cranes commonly range from 2 ton up to 20 ton, but the rated capacity alone isn't enough.

Consider:

- Actual load weight – the heaviest item you'll lift regularly

- Lifting accessories – hooks, grabs, magnets, or C-hooks add extra weight

- Safety margin – typically 20–30% above your heaviest load to avoid overloading

Tip: Always plan for occasional heavier loads. Underestimating can lead to downtime or costly repairs.

Span, Lifting Height, and Coverage

The crane's span and lifting height determine how well it serves your indoor space.

- Span: based on building width, column spacing, and runway beams

- Lifting height: depends on roof clearance and hoist type; low-headroom hoists can help in tight spaces

- Coverage: ensures all workstations or storage areas are accessible without moving the crane unnecessarily

Tip: Measure your facility carefully and plan for future layout changes. Even a slightly wider span can prevent operational headaches later.

Duty Class and Working Frequency

Duty class tells you how often and how intensively the crane will be used. Picking the right class prevents premature wear and reduces maintenance.

- Light duty: occasional lifts, a few cycles per day

- Medium duty: daily use with moderate frequency

- Heavy duty: continuous operation, production lines, or frequent heavy lifts

Tip: Choosing a slightly higher duty class than your average use gives reliability for unexpected peak loads.

Indoor-Specific Design Considerations

Indoor overhead cranes need more than lifting capacity. Their design must match the building structure, electrical setup, and working environment to operate safely and efficiently.

Building Structure and Runway Loads

The building itself plays a major role in crane selection. You can't just pick any crane and install it—your runway beams, columns, and roof must support it.

Key factors to check:

- Runway beams and column strength – heavier cranes need stronger beams and wider column spacing

- Roof and ceiling limits – low-headroom buildings may need special hoists or underhung designs

- Retrofit vs. new construction – retrofitting requires careful measurement and load analysis, while new buildings allow more flexibility

Tip: Always have a structural engineer verify load capacity. Even a well-built crane can cause damage if the building isn't prepared.

Power Supply and Control Systems

Indoor cranes rely on reliable electricity and precise control. Choosing the right system ensures smooth, safe, and consistent operation.

Considerations include:

- Voltage compatibility – common indoor voltages: 380V, 400V, 415V three-phase

- Control method – pendant control for simplicity, wireless remote for flexibility and safer operation

- Smooth start and braking – prevents jerks, protects loads, and reduces stress on building structure

Tip: For delicate indoor operations, soft-start motors and proportional controls can make lifting safer and more precise.

Noise and Environmental Conditions

Indoor cranes work close to people and sensitive equipment. Noise and environmental factors matter more than for outdoor cranes.

Key points to consider:

- Low-noise motors and gearboxes – important for enclosed workshops and offices nearby

- Special environments – cleanroom, food-grade, or pharmaceutical facilities may require dust-proof or stainless-steel components

- Temperature and humidity – cranes in hot, humid, or air-conditioned areas may need corrosion-resistant materials

Tip: Plan for environmental conditions when choosing motors, hoists, and protective coatings to avoid premature wear.

Electric Hoist Selection for Indoor Overhead Cranes

Choosing the right electric hoist is just as important as selecting the crane itself. The hoist determines how smoothly and safely loads move, how much maintenance is needed, and how long the crane lasts.

Wire Rope Hoists

Wire rope hoists are ideal for higher lifting heights and heavier loads. They run smoothly, handle frequent use well, and are reliable for indoor industrial environments.

Advantages:

- Handles heavier or irregular loads

- Smooth and precise lifting and lowering

- Long service life with proper maintenance

Best for: workshops or warehouses with medium to heavy lifting requirements.

Chain Hoists

Chain hoists are compact and lightweight, making them suitable for lighter loads or low-headroom spaces.

Advantages:

- Smaller footprint, easier installation in tight spaces

- Lower initial cost for light-duty applications

- Simple maintenance and operation

Best for: small workshops, light assembly lines, or areas with limited headroom.

European-Style Hoists

European-style hoists combine the benefits of wire rope and modern engineering. They offer higher efficiency, smoother operation, and longer service life compared to standard hoists.

Advantages:

- Faster lifting speeds and smoother motion

- Better energy efficiency and reduced wear on crane components

- Ideal for frequent, heavy-duty indoor use

Tip: Selecting the right hoist is not just about load capacity. Consider lifting speed, headroom, duty cycle, and maintenance requirements to maximize performance and longevity.

Customization Options for Indoor Overhead Cranes

Indoor overhead cranes are not one-size-fits-all. Customization allows your crane to fit your facility, workflow, and lifting requirements perfectly. Thoughtful design ensures safety, efficiency, and long-term value.

Low-Headroom Overhead Crane Designs

Some workshops and warehouses have limited vertical space. Standard cranes may not fit or may reduce lifting height. Low-headroom designs solve this:

- Optimized hoist placement – keeps the crane compact without reducing capacity

- Reduced crane beam depth – fits tight ceiling spaces

- Improved hook approach – maximizes lifting height in constrained buildings

Practical tip: Low-headroom cranes are ideal for retrofit projects or older buildings where roof height is fixed.

Special Lifting Attachments

Different materials and loads require specialized lifting tools. Custom attachments improve handling efficiency and safety:

- C-hooks – for coils or drums

- Grabs/clamps – for slabs, bars, or sheet metal

- Electromagnets – for steel handling in workshops or warehouses

- Vacuum or custom tooling – for lightweight or delicate items

Practical tip: Choose attachments that match both the load type and the crane's rated capacity. Overloading a grab or magnet can damage both the crane and the material.

Expansion-Ready Crane Systems

Planning for the future can save costs later. Some cranes are designed to be modular and upgradeable:

- Allow longer spans or additional cranes to be added later

- Support higher lifting capacity or additional hoists if production grows

- Compatible with automation or remote operation upgrades

Practical tip: If your workflow may expand or the facility layout changes, investing in an expansion-ready crane avoids costly replacements.

How to Choose a Reliable Indoor Overhead Crane Supplier

Selecting the right supplier is just as important as choosing the crane itself. A trusted supplier ensures the crane is designed for your facility, meets safety standards, and comes with long-term support.

Manufacturing Experience and Certifications

A supplier's experience indicates their ability to handle complex indoor crane projects. Look for:

- Years of industrial crane manufacturing – more experience usually means better engineering and quality control

- Certifications – ISO 9001 for quality management, CE for European safety compliance, FEM for duty classifications

- Third-party inspection reports – verify build quality, load testing, and safety standards

Tip: A certified manufacturer reduces risk of delays, non-compliance, or unexpected failures.

Indoor Project References

Check if the supplier has completed projects similar to yours. Ask for:

- Case studies or photos of workshop, warehouse, or factory installations

- References from clients in similar industries

- Evidence of handling low-headroom, light-duty, or heavy-duty indoor cranes

Tip: Suppliers with relevant experience understand indoor constraints like ceiling height, building loads, and cleanroom requirements.

Engineering Support and After-Sales Service

A good supplier provides ongoing support beyond delivery. This includes:

- Engineering advice on crane type, span, lifting height, and attachments

- Installation guidance and commissioning support

- Operator training, preventive maintenance schedules, and troubleshooting

Tip: Ask about availability of remote support or local service partners, especially if your facility is far from the manufacturer.

Availability of Spare Parts and Documentation

Long-term maintenance depends on accessible parts and clear manuals. Verify:

- Spare parts availability for hoists, controls, and mechanical components

- Detailed technical documentation, wiring diagrams, and maintenance manuals

- Guidance on inspection schedules and safety checks

How to Choose a Reliable Indoor Overhead Crane Supplier

Selecting the right supplier is just as important as choosing the crane itself. A trusted supplier ensures the crane is designed for your facility, meets safety standards, and comes with long-term support.

Manufacturing Experience and Certifications

A supplier's experience indicates their ability to handle complex indoor crane projects. Look for:

- Years of industrial crane manufacturing – more experience usually means better engineering and quality control

- Certifications – ISO 9001 for quality management, CE for European safety compliance, FEM for duty classifications

- Third-party inspection reports – verify build quality, load testing, and safety standards

Tip: A certified manufacturer reduces risk of delays, non-compliance, or unexpected failures.

Indoor Project References

Check if the supplier has completed projects similar to yours. Ask for:

- Case studies or photos of workshop, warehouse, or factory installations

- References from clients in similar industries

- Evidence of handling low-headroom, light-duty, or heavy-duty indoor cranes

Tip: Suppliers with relevant experience understand indoor constraints like ceiling height, building loads, and cleanroom requirements.

Engineering Support and After-Sales Service

A good supplier provides ongoing support beyond delivery. This includes:

- Engineering advice on crane type, span, lifting height, and attachments

- Installation guidance and commissioning support

- Operator training, preventive maintenance schedules, and troubleshooting

Tip: Ask about availability of remote support or local service partners, especially if your facility is far from the manufacturer.

Availability of Spare Parts and Documentation

Long-term maintenance depends on accessible parts and clear manuals. Verify:

- Spare parts availability for hoists, controls, and mechanical components

- Detailed technical documentation, wiring diagrams, and maintenance manuals

- Guidance on inspection schedules and safety checks

FAQs: Key Buyer Questions This Article Solves

What type of overhead crane is best for a workshop or warehouse?

The best type depends on load size, building constraints, and lifting frequency.

- Single girder cranes are ideal for light to medium loads and limited headroom.

- Double girder cranes handle heavier loads, wider spans, and frequent use.

- Underhung (underrunning) cranes work well where floor space is tight or ceiling height is limited.

How many tons of lifting capacity do I really need for indoor operations?

Consider the heaviest load plus lifting tools and a safety margin. Typical indoor cranes range from 2 to 20 tons.

- Include accessories like hooks, grabs, or magnets in the calculation.

- Add 20–30% safety margin to prevent overloading.

- Match the crane's duty class to daily lifting frequency to avoid premature wear.

Can my existing building support an overhead crane installation?

Yes, but you must evaluate the structural capacity first:

- Check runway beams, column strength, and ceiling load limits.

- For retrofit projects, a structural engineer may recommend reinforcements.

- Low-headroom or underhung cranes may be necessary for older buildings.

Should I choose a single girder or double girder overhead crane indoors?

- Single girder cranes – cost-effective, lighter loads, easier to install, suitable for small to medium workshops.

- Double girder cranes – higher capacity, longer spans, better stability, ideal for heavy-duty indoor operations.

- Consider load weight, frequency, building headroom, and future expansion before deciding.

What safety standards and certifications are required for indoor cranes?

Indoor cranes must comply with international and local safety regulations:

- CE – European safety standard

- ISO – quality and performance standards

- FEM – duty classification and crane safety

- Local regulations – country-specific industrial safety rules

- Essential safety features include overload protection, limit switches, emergency stops, smooth braking, and anti-sway mechanisms.

How much does an indoor overhead crane cost, and what affects the price?

Crane price depends on several factors:

- Type of crane – single girder vs. double girder vs. underhung

- Lifting capacity – heavier loads cost more

- Span and lifting height – wider spans and higher lifts increase material and engineering costs

- Customization – low-headroom designs, special attachments (C-hooks, grabs, magnets), and expansion-ready systems

- Manufacturer and certifications – reputable suppliers with CE, ISO, or FEM certifications may cost more but provide long-term reliability

Conclusion: Selecting the Right Overhead Crane for Indoor Use

An indoor overhead crane is more than equipment—it’s a long-term investment that affects safety, workflow efficiency, and productivity. Choosing the right crane requires careful consideration of several factors:

- Application requirements – type of load, lifting frequency, and workflow patterns

- Building conditions – ceiling height, column spacing, and runway strength

- Crane type and hoist selection – single girder, double girder, underhung, wire rope, or chain hoist

- Customization options – attachments, low-headroom designs, and expansion readiness

- Supplier capability – certifications, project references, engineering support, and spare parts availability

Selecting a crane based only on price or capacity can lead to operational issues, downtime, and safety risks. The best solution is a crane that matches your real indoor workload, fits your building, and supports long-term, safe, and efficient operations.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch