5-Year Cost Planning Guide for 10 Ton Overhead Crane Buyers

A practical roadmap to budget purchase, maintenance, and upgrades, helping buyers maximize reliability and minimize unexpected 10 ton overhead crane costs.

Category: Featured

Your Trusted 10 Ton Overhead Crane Manufacturer & Supplier

5 Year Cost Planning Guide for 10 Ton Overhead Crane Buyers

Good Price Customized 10 Ton Overhead Bridge Cranes & Eot Cranes for Sale

Introduction

Why 5-Year Cost Planning Matters for Overhead Crane Investments

Buying an overhead crane—especially a 10-ton unit—isn't just a one-time payment. It's a long-term decision tied to your plant's safety, production uptime, and maintenance planning. Too often, companies focus only on the crane's initial cost and forget what comes after: servicing, spare parts, operator training, downtime, and eventually, upgrades or replacement. A proper 5-year cost plan gives you a clear roadmap. No surprises. No scrambling for budget approvals mid-operation.

- A 10-ton crane typically lasts 10 to 15 years when maintained well.

- The first 5 years cover the steepest learning curve and most cost variation.

- Planning early helps reduce downtime, avoid emergency costs, and improve ROI.

Why You Need to Think Beyond the Purchase Price

The price on your quotation is just the beginning. You'll need to factor in installation, structure preparation, logistics, and testing. Then come the recurring costs—routine maintenance, unexpected repairs, spare part stocking, and mandatory inspections. If you don't plan for these from the start, small issues can become costly problems.

- Many first-time buyers underestimate operating costs by 20–30%.

- Spare part shortages and delayed maintenance are common sources of downtime.

- Software updates, re-certification, and staff retraining all add up over time.

What This Guide Focuses On: The 10-Ton Overhead Crane

This guide focuses specifically on the 10-ton overhead crane—a popular choice for workshops, manufacturing plants, steel fabricators, and maintenance depots. It's a flexible capacity that suits most medium-duty operations and is commonly used in:

- General fabrication workshops and industrial warehouses

- Machinery repair shops and heavy maintenance departments

- Plastic, metal, and woodworking production plants

- Logistics and transfer bays inside process plants

Typical buyers include:

- Engineering and procurement teams specifying for expansion projects

- Factory owners replacing older cranes

- Maintenance managers looking to build a long-term service budget

If you're investing in a 10-ton crane or responsible for planning its costs, this guide is made to help you build a reliable, justifiable 5-year budget—line by line. Let's get into it.

Total Cost of Ownership (TCO)

What Does Total Cost of Ownership Really Mean?

Total Cost of Ownership (TCO) means exactly what it says: everything you'll spend over the life of your 10-ton overhead crane—not just what you pay upfront. It includes what it costs to buy, install, operate, maintain, and eventually upgrade or replace the crane. For most buyers, focusing only on the price of the crane itself leads to cost overruns and unexpected downtime. TCO thinking helps you plan smarter and avoid surprises down the road.

- TCO gives a full picture of cost over 5–10 years.

- It shows how small overlooked expenses (like brake pad changes or cable replacements) stack up.

- It helps justify your purchase to finance and production with long-term numbers, not just a one-time quote.

Initial Cost vs. Long-Term Expenses: What's the Difference?

It's easy to compare crane offers by price per unit or per ton. But that's just the beginning. The initial cost covers the crane itself and maybe the install. The long-term expenses? That's where the real money often goes.

- Initial cost: equipment, installation, testing, and commissioning.

- Long-term cost: spare parts, downtime, service labor, inspections, certification, and upgrades.

A crane that costs 15% more up front but saves 25% in operating costs over five years is the better deal. But you only see that when you run the numbers.

Key TCO Components for a 10-Ton Overhead Crane

Let's break down the major areas you'll need to plan for when calculating the true cost of a 10-ton crane:

- Equipment cost: The crane system itself—hoist, trolley, bridge beam, controls, and safety components. Also includes accessories like remotes, limiters, and overload protection.

- Installation cost: Includes everything from runway beams and power supply to civil works and structural modifications. Also covers testing, load certification, and commissioning.

- Operating and maintenance expenses: Day-to-day usage, power consumption, routine inspections, preventive servicing, and general upkeep. Also includes training for operators and maintenance staff.

- Spare parts and repair costs: Budget for brake pads, wire ropes, limit switches, wheels, contactors, and other consumables that wear out over time. For some parts, you'll want to keep extras in stock.

- Downtime and productivity loss risks: Every hour your crane is down, production is delayed. Budgeting for fast repairs, spare part availability, and support helps reduce costly idle time.

- Upgrade and expansion costs: As your plant grows, you might add features like remote control, automation, or higher speed drives. Planning for these now makes future expansions smoother.

5 Year Cost Planning Guide for 10 Ton Overhead Crane Buyers

Year 0: Purchase and Installation Phase

The purchase and installation phase is when most of your capital expenditure (CAPEX) is spent. While it's tempting to focus only on the crane price, the truth is, the actual equipment is just one part of the full picture.

Getting this phase right saves you headaches later—especially if you're working with tight ceiling height, limited floor space, or strict timelines for production.

Key Expenses to Plan For

Crane price: The crane cost varies depending on the design you choose.

- Single girder cranes are generally more economical and lighter but may have lower lifting height.

- Double girder cranes offer better hook height and more robust performance.

- European-type designs are more compact and efficient but typically come at a higher unit price.

- Freight, import duties, and insurance: If you're buying from overseas (e.g., China), don't forget these extras. Ocean freight, local transport, customs clearance, and insurance can easily add 10–20% to the cost.

- Civil works and structure adaptation: If your workshop needs runway beams, concrete columns, anchor bolts, or supports, this can become a major cost. Always get structural drawings reviewed before ordering.

- Runway beam and rail installation: Runway alignment and leveling are essential. Misalignment leads to premature wheel wear and mechanical stress. Budget for grouting, shimming, and alignment labor.

- Electrical and power supply connection: This includes the main power cable, circuit breaker, isolator, earthing, festoon or busbar, and local wiring. Voltage drop, harmonics, and power availability all need to be checked.

- Commissioning and testing: Your crane isn't operational until it passes final checks. This includes hoist/lift trials, brake tests, limit switch calibration, and a load test (usually 125% of rated capacity). Certified documentation is often required.

Recommendations for This Phase

- Choose a supplier with transparent pricing: Insist on a breakdown of all costs: crane components, control system, painting, documentation, packing, spare parts, shipping, and taxes. Avoid lump sum offers with vague descriptions.

- Plan for local installation support: Will the supplier send their team? If not, find a local technician experienced with overhead cranes. Ask who's responsible for tools, scaffolding, and safety gear.

- Consider lifetime cost, not just the upfront quote: A cheaper crane may cost more to maintain. Look at motor brands, control systems, spare part availability, and energy efficiency over 5 years.

Year 1–2: Initial Operation and Learning Curve

Once the crane is installed and running, you enter a new phase: actual usage. These first two years are crucial. Operators are learning, your maintenance team is getting familiar, and small oversights can lead to avoidable downtime.

It's also the time when most warranty claims happen—so tracking performance and wear is important.

Expected Costs in Year 1–2

- Operator training: A well-trained operator handles loads more smoothly, reducing brake and gearbox wear. Invest in proper training during handover, and offer a refresher within the first year.

- Preventive maintenance contracts: Start early with monthly and quarterly check-ups. If you don't have in-house capability, partner with a reliable local service provider for inspections and tune-ups.

- First-year warranty checks and parts replacement: Not everything is covered. Brake linings, rope tension adjustments, and wear-related items like buffers or limit switches are usually excluded. Know what's included, and keep a record of failures.

Strategies to Avoid Problems Early

- Schedule regular inspections (monthly, quarterly): Don't wait for something to break. Even visual checks can catch early signs of trouble: oil leaks, loose bolts, worn rope, dirty control panels.

- Train in-house staff for basic troubleshooting: Teach your technicians how to reset the control panel, check overloads, inspect brake gaps, and adjust limit switches. This saves time and cuts service costs.

Keep initial spare parts stock: Stock the basics from day one so you're not stuck waiting for international shipping:\n

- Brake pads or complete brake kits

- Limit switches for hoist and travel

- Wire rope (pre-measured and reeved) or chain

- Remote control battery packs and transmitters

- Contactors and relays

Year 3–4: Maintenance and Wear Phase

After two years of regular operation, most cranes start to show wear in predictable places. This is when your preventive maintenance program really proves its worth. If you've been keeping good records and replacing small parts before failure, you'll avoid major disruptions. If not, now's the time to catch up.

This phase is also where a lot of owners get caught off guard by sudden costs—especially if the crane has been running more frequently than expected or in a harsher environment than initially planned.

Common Expenses in Year 3–4

- Replacement of hoist brake, wire rope, and contactors: These are wear items that have a finite lifespan. Their actual timing depends on usage frequency, load types, and maintenance habits.

- Wheel tread wear: Worn wheels cause alignment issues and rail damage. If your crane is traveling frequently or over long spans, expect to see wear by now.

- Electrical control system tune-up or component replacements: VFD fans and filters, panel relays, and limit switches can degrade over time, especially if the panel isn't sealed from dust or moisture.

Tips to Manage This Phase Efficiently

- Use OEM parts to avoid compatibility issues: It's tempting to save money with generic or locally made components, but mismatched parts (especially brakes or contactors) often fail early or void warranty coverage.

- Budget 3–5% of crane value annually for maintenance: This range fits most medium-duty operations. Increase the percentage if your crane is in heavy use or running outdoors.

- Monitor crane usage frequency to adjust service intervals: Install a running hours meter or use your VFD's internal counters. Cranes used more than 6 hours per day typically require shorter inspection cycles.

Year 5: Assessment and Upgrade Planning

Five years in, your crane has done real work—and it's time to assess what's next. This is the point where small fixes aren't enough, and you may need to make more serious decisions.

Some cranes continue to run well with proper upkeep. Others may start to show their age, especially if production demands have increased or the crane was originally undersized.

Cost Items to Expect in Year 5

- Major refurbishments or upgrades: Items like motor rewinding, gearbox overhauls, brake group replacement, or control panel rewiring might now be on the table. If your crane runs with older control systems, this is the time to consider modernizing.

- Optional automation retrofits: Upgrades like wireless remotes, PLC integration, variable speed control, or anti-sway systems can improve safety and handling. These are ideal if you're scaling up operations or trying to reduce manual errors.

- Re-certification or load testing for compliance: Most jurisdictions require periodic third-party inspections or re-certification every 3 to 5 years. Schedule this ahead of time and budget for both the test and any adjustments required afterward.

Actions to Take During This Phase

- Conduct a professional inspection and condition assessment: This goes beyond your regular maintenance checks. Bring in a certified inspector or crane technician to assess structure, mechanics, electrics, and safety devices.

- Evaluate productivity gains vs. cost of a new crane: If the crane's downtime, repair costs, or performance limitations are creeping up, compare the upgrade cost with a replacement quote. In some cases, upgrading isn't worth it.

- Prepare a budget for possible replacement after 8–10 years: While many 10-ton cranes last longer than a decade, a proactive replacement plan ensures you don't face a breakdown during peak production without a backup.

Factors That Influence 5-Year Cost Planning

It's not enough to plan based on averages—because not every 10-ton overhead crane lives the same life. The actual wear rate, maintenance needs, and operating costs over five years depend heavily on your specific use case. Below are four key factors that have a direct impact on your total cost plan.

Usage Intensity

How often and how hard your crane works directly affects how much you'll spend to keep it running. A lightly used crane in a maintenance bay is very different from one running 24/7 in a production line.

- Single-shift operation (8 hours/day, 5 days/week):

Generally low wear and fewer replacements in the first 3–4 years. Maintenance costs stay closer to 2–3% of crane value annually. - Multi-shift or continuous use:

Accelerated wear on brakes, contactors, wheels, and wire rope. May need more frequent inspections and a larger spare parts pool. Plan for 4–6% of crane value per year in maintenance.

Environmental Conditions

The crane's working environment has a huge impact on maintenance intervals and part lifespans. Harsh conditions demand more frequent checks and specialized components.

- Indoor use in clean, temperature-controlled environments:

Lowest risk of corrosion, dust ingress, and electrical problems. Ideal for standard designs with minimal protection features. - Outdoor use or semi-covered areas:

Requires weatherproof enclosures, sealed brakes, corrosion-resistant finishes, and extra attention to electrical connections. Frequent exposure to sun, rain, or wind shortens component life.

Dust, humidity, and temperature extremes:

- Foundries, cement plants, and metal shops introduce fine particulates that damage hoists and VFD fans.

- High humidity leads to rust on wire rope and contactor oxidation.

- Cold environments may require special lubricants and heating elements in control cabinets.

Crane Design Type

The design you choose will influence not just initial cost, but long-term serviceability and maintenance complexity.

- Standard cranes (single girder, conventional hoist):

Easier to maintain, and spare parts are widely available. Suitable for general industry use with light to moderate duty cycles. - Low headroom or compact European designs:

Save space and reduce dead weight, but may require brand-specific spares and more precise alignment during installation. - Explosion-proof (EX) cranes:

Required in oil, gas, paint, and chemical environments. Higher up-front cost, plus longer lead times and tighter inspection standards. Electricals, motors, and brakes are all specialized and more expensive to replace.

Supplier Support and Spare Parts Access

Your crane is only as reliable as the team that supports it. Even a top-quality crane can become a headache without responsive service and quick spare part access.

- Local service availability:

Can your supplier send a technician within 24–48 hours? Are they trained to handle your specific crane model and controls? - Spare parts lead time:

Are parts stocked locally, or will you wait weeks for international shipping? For remote areas, it's often smarter to keep a critical parts kit on-site.

When requesting quotes, ask not only for the crane price but also for a recommended 5-year spare parts list, service response policy, and whether they offer a long-term maintenance contract. This helps you choose not just a product—but a partner.

Sample 5-Year Cost Projection Table

When planning for a 10-ton overhead crane, it helps to visualize how costs spread out over the first five years. The table below outlines typical cost categories you should include in your budget, based on moderate-duty usage (single or dual shift, indoor operation).

Note: The values are sample estimates. Actual figures depend on crane design, environment, workload, and supplier terms.

5-Year Overhead Crane Cost Planning Table

The follow table is for your reference, if you need a 10 ton overhead bridge crane, please feel free to contact us to get your tailored solution.

| Cost Category | Year 0 | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 | 5-Year Total |

|---|---|---|---|---|---|---|---|

| Equipment & Installation | $42,000 | – | – | – | – | – | $42,000 |

| Routine Maintenance | – | $1,200 | $1,500 | $1,800 | $2,000 | $2,200 | $8,700 |

| Spare Parts | – | $300 | $600 | $900 | $1,200 | $1,500 | $4,500 |

| Major Repairs/Upgrades | – | – | – | – | $2,500 | $3,000 | $5,500 |

| Total Annual Estimate | $42,000 | $1,500 | $2,100 | $2,700 | $5,700 | $6,700 | $60,700 |

How to Use This Table

- Year 0 includes all initial investment: equipment, shipping, installation, commissioning.

- Years 1–2 are generally low-cost years if usage is moderate and the crane is well installed.

- Years 3–4 see increased maintenance and part replacement needs.

- Year 5 is a checkpoint for major repairs, upgrades, or control system modernization.

Practical Tips for Budgeting

Budgeting for your 10-ton overhead crane over five years can seem daunting, but a few simple habits make a big difference.

- Always add a 10–15% buffer for unforeseen costs: No matter how well you plan, unexpected repairs or price increases happen. This safety margin helps avoid last-minute budget shortfalls.

- Invest in predictive maintenance tools if usage is heavy: Devices like vibration sensors or running hours meters help catch issues early. They reduce costly downtime and extend component life.

- Evaluate service contracts for better long-term savings: A good service contract with your supplier or a trusted local partner often costs less than paying for emergency repairs and rush parts separately.

- Keep track of crane performance and maintenance logs: Document everything—from daily inspections to parts replaced. This data helps spot trends and supports warranty claims if needed.

Conclusion

Planning your 5-year overhead crane budget isn't just accounting—it's about securing your operation's future.By thinking beyond the purchase price and preparing for maintenance, repairs, and upgrades, you save money and avoid surprises.The right 10-ton crane combined with smart maintenance is a recipe for smooth production and long-term savings.

Ready to plan your crane investment with confidence?Contact us for a customized 5-year cost plan and detailed proposal tailored to your facility's needs. We'll help you get the most value and reliability out of your crane—right from day one.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

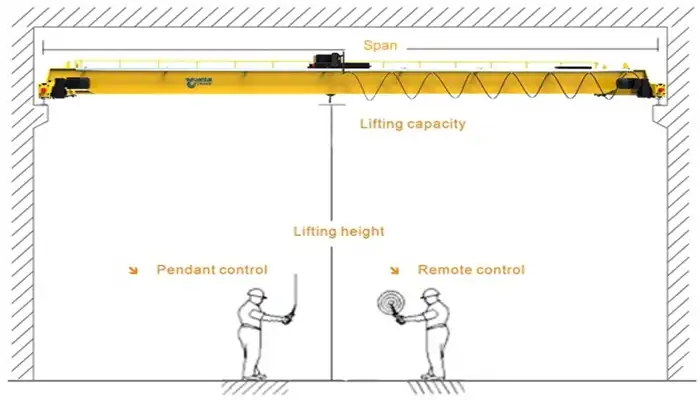

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch