Cantilever Crane: Cantilever Jib Crane Design & Fabrication

0.25-20 ton cantilever cranes for sale, types of cantilever jib crane designs,- column jib cranes & wall cantilever jib cranes in wall travelling crane & wall mounted crane design.

Category: Euro Hoist Crane

Your Trusted Cantilever Jib Crane Manufacturer & Supplier

Cantilever cranes Design & Fabrication

FEM, DIN & ISO Standards Cantilever Jib crane , Advanced Cranes Designs

0.25-20 ton cantilever cranes for sale, types of cantilever jib crane designs,- column jib cranes & wall cantilever jib cranes in wall travelling crane & wall mounted crane design.

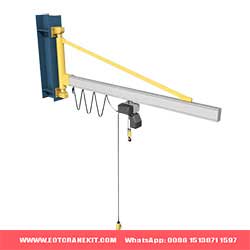

European style cantilever cranes systems is new type of jib cranes, designed on European DIN/FEM standards with the features of compact structure, light weight, modular design, advanced manufacturing and processing technology, high security & reliability, free-maintenance ,low-energy consumption , and environment friendly. The cantilever jib cranes can be designed into column jib crane and wall jib crane with various different types of cantilever designs including the I beam cantilever crane, enclosed track cantilever crane and process cantilever crane, etc.

Column mounted cantilever jib crane

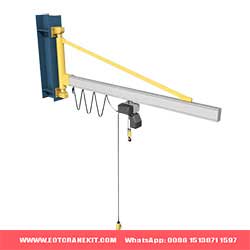

Wall mounted cantilever jib crane

Wall travelling cantilever jib crane

Why to use a cantilever crane

Due to the unique features of crane designs, the cantilever jib cranes are widely used for the following features;

- As a newly designed overhead travelling cranes,the slewing cantilever cranes is favored due to its high flexibility which can be operated with rotation of 90 °, 180°, 270°& 360°etc.

- With special cantilever crane structures, the cantilever jib cranes can provide high safety, high reliability, high efficiency and provide time saving and an very saving solution for you.

- Due to design of covering small working area , cantilever crane is easy to be operated and maintained, an economical and durable small crane.

Various cantilever cranes designs , wide cantilever crane specifications

From light duty I beam hoist jib crane to heavy duty box girder hoist winch jib crane with capacity from 500kg up to 320 tons are available from us, your honest and trusted cantilever crane manufacturer and crane supplier. Our cantilever crane are designed based on FEM, DIN standards with wide cantilever crane specifications at good cantilever crane price.

Column jib cranes

What is a column jib crane? The column mounted cantilever crane refers to the cantilever jib crane with supporting column or pillar mounted on floor, which also called pillar jib crane or free standing cantilever jib crane. The column cantilever crane can be grouped into three types based on the column mounting type including base-plate mounted pillar cantilever crane, insert mounted pillar cantilever crane and sleeve insert mounted pillar cantilever crane, etc. ,

Column mounted slewing cantilever crane

- Lifting capacity of column jib crane: 0.5~15t

- Effective arm length of column jib crane: 5m~8m

- Rotary degree of column jib crane: 180º 270º 360º optional

- Process column jib crane are available, equipped with chain hoist and wire rope hoist, powered manual ly or electrically.

There are three main designs for column cantilever cranes, in terms of how they can be mounted and installed:

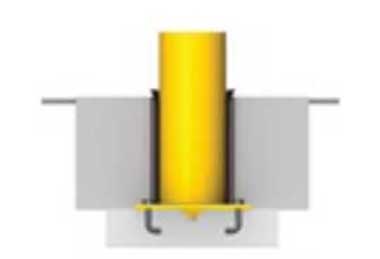

Base-plate mounted cantilever jib crane is the most popular jib crane design with the the easiest way of crane installation. The mast or column is installed and fixed by bolting a base plate onto a reinforced concrete foundation and then reinforcing the column with gussets.

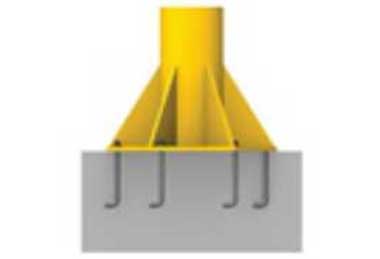

Foundation/insert mounted cantilever crane is designed with a welded steel plate at the bottom of the column which is anchored during the first-pour concrete footing. A second concrete pour supports the crane column or pillar but without the requirement of gussets.

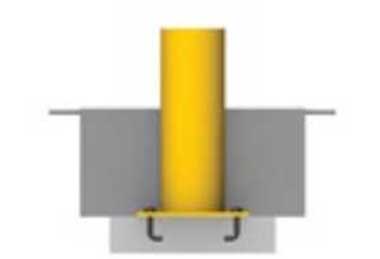

Sleeve-insert mounted cantilever jib crane is designed with flexible relocation if required without damaging the column.The cantilever is designed to construct a separate steel sleeve installed permanently in the concrete floor., which enables the column to be slid into or removed out of the sleeve quickly and easily.

Compared to other cantilever crane systems, freestanding jib crane systems offer the highest capacities, longest spans, and greatest amount of rotation. However, freestanding cantilever cranes are among the most expensive systems and the most permanent setup due to the special foundation that is required to anchor and secure the crane and support the load during a lift.

Under many conditions there is no limit to the pillar mounted cantilever crane to be used alone or to cooperate with other cranes in the plant. The whole material handling solution is clean and neat. You can consider purchasing in the early stage of the building or later. In terms of overall investment saving, pays more attention than you.

Light duty column cantilever crane with tie rod cantilever design with capacity up to 2 000kg

Column cantilever crane with European electric chain hoist with capacity up to2 000kg

Column cantilever crane with European style low headroom electric wire rope hoist with capacity up to 5 000kg

Column cantilever crane with light duty euro hoist design and with capacity up to 1000kg

The column jib crane or free standing jib crane is the most common type of jib system which can be installed for indoor use and outdoor use. Cantilever freestanding cranes can be operatedunderneath large overhead travelling crane systems as a supporting crane system or work independently in a workcell. The column jib cranes also can be used outdoors at marinas or loading docks, etc.

We provide tailored cantilever jib cranes solutions to fit your specific requirements. The pillar mounted cantilever crane ensures that the loads or work pieces can be hoisted and transported quickly and easily and deposited gently and precisely. The freestanding cantilever cranes is widely used in workshop, warehouse, wharf and other fixed places, etc. Contact us to get your cantilever jib crane design and jib crane price.

Wall cantilever jib crane with wall mounted design

Wall mounted cantilever cranes is a type of small cantilever crane which is mounted on walls or columns. Wall cantilever crane systems is the space-saving cantilever crane designs,offering maximum clearance above or beneath the cantilever, used in individual bays, along structurally adequate walls or building support columns, or as a supplement to an existing monorail or overhead travelling crane or bridge crane. Wall cantilever cranes has no need of foundations, but need a wall or support column of the build .

Wall cantilever jib crane is widely used for material handling on work station, especially in some small application area. With cantilever fixed to the wall or cement column or other supporting structure, the advantages of wall cantilever jib crane includes saving the ground space for setting a column, Simple installation, the low headroom design with lesser space requirement but higher hoisting height.

- Lifting capacity of wall cantilever jib crane: 0.25~3t

- Slewing radius wall cantilever jib crane: 5m~12m

- Rotary degree wall cantilever jib crane: 180º

- Wall mounted slewing cantilever crane is widely used for material handling on work station, especially in some small operation area.

Wall travelling cantilever cranes

Wall traveling cantilever crane is a special type of wall cantilever jib crane used in the workshop of machine manufacturing and assembling. It travels along the rail mounted on the wall or other support structure on the elevated orbit of a multi-layer assembly shop. The wall travelling cantilever crane can save the more manufacture place and can operate flexible. The wall traveling cantilever crane is divided into two kinds according to different main girders, we use electric hoist for single girder structure and usage. Process designs are available for wall travelling cantilever jib cranes.

Wall traveling cantilever crane

- Lifting capacity of wall cantilever jib crane: 0.5~3t

- Slewing radius of wall cantilever jib crane: 5m~12m

- Wall traveling cantilever crane is a special crane used in the workshop of machine manufacturing and assembling. The travelling crane travels along the rail mounted on the wall or other support structure on the elevated orbit of a multilayer assembly shop.

The wall cantilever cranes can be grouped in wall mounted cantilever crane & wall travelling cantilever cranes with the different cantilever designs such as Cantilever crane design & Tie-Rod Supported cantilever crane designs, and i beam cantilever crane design, etc.

Wall mounted cantilever crane with electric chain hoist with enclosed track arm in tie rod design with capacity up to 1000kg

Wall mounted wire rope hoist cantilever crane with i beam arm design with capacity up to 3000kg

Wall mounted electric chain hoist cantilever crane i beam arm in tie-rod design with capacity up to 2 000kg

Wall mounted euro hoist cantilever crane with i beam design and capacity up to 2 000kg

Applications of cantilever crane

- Cantilever cranes are widely applied for loads handling in short distance or in serried places in working cells ,and also used outdoor as lifting tools outdoors. Application places of cantilever cranes are including workstations, workshops, storage, yard and other fixed or localized places, etc.

- Working with the overhead cranes, the supplement rotating cantilever cranes can effective complete the work of the overhead travelling crane systems.

- The slewing cantilever cranes are designed to be used in the mentioned application environment : Ambient temperature: -25℃ to + 40 ℃ , Humidity ≤85%; Elevation below 1000m;

- Cantilever cranes with standard cantilever crane designs are forbidden to be used in dangerous environment, such as explosive, inflammable, and corrosive , etc., in which the processed non standard Cantilever cranes with special crane designs are needed.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch