Synchronized Hoist Bridge Crane for Wood Board Lumber Warehouse

Synchronized Hoists Overhead Crane for Lumber Warehouse

Double girder overhead crane with synchronized hoists for wood broad lumber warehouse material handling. Check synchronized hoists and crane case study now.

Basics of Synchronized Hoists Overhead Cranes for Sale Maldives

- Crane Type: 3 Ton + 3 Ton Double Girder Overhead Crane

- Date of Placing Oder: 2020.03.16

- Date of Delivery : 2020.4.15

- Way of Transportation: By Sea,20GP & 40 GP containers

- Way of Payment: TT

- Destination country: Maldives

- Destination port:CNF, Male

- Application : Wood Industry

Background of wood board lumber warehouse

Maldives Client has a good rapport with regional government officials and has worked in the wood and timber industry for more than 40 years. The main point of contact is the sixty-year-old boss of the Maldive timber factory, a nice, gentle man who knows exactly what he needed and a reliable businessman who always keeps his word. It is a real pleasure to work with him.

Lumber warehouse for double girder overhead crane installation

Typical requirements of synchronized hoist cranes

The features of double girder overhead crane needed for the Maldives timber workshop are as following for your refernece.

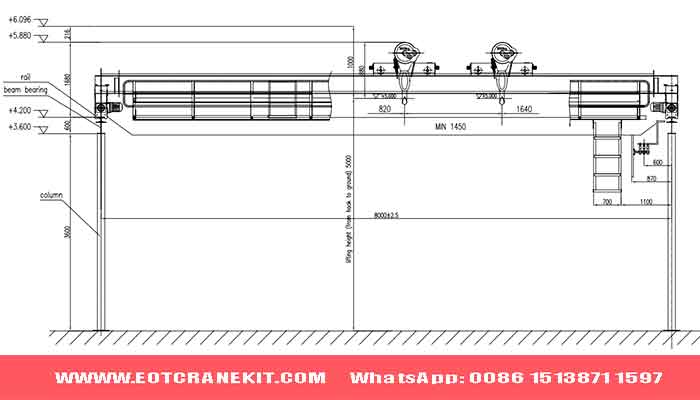

- Existing factory building with constrained dimensions and weak supporting pillars.

- "Span needs to be maximized and the width of supporting columns needs to reduced.

- Maximum lifting height: The main beam's steel plate is thickened, resulting in a shorter height.

- End beam/End carriage minimization; compact layout; European-style structure.

Simply, the 3 ton + 3 ton synchronized hoist overhead crane must be designed with the smallest size or dimensions while also having the greatest working coverage in the lumber warehouse and workshop due to the limitations of a small available space and a sparse supporting structure warehouse facility.

Synchronized hoist crane solutions for lumber warehouse

Based on lumber warehouse of Maldives client lifting requirements and application conditions. The double girder overhead cranes with 3 ton + 3 ton synchronized hoist overhead crane are suggested for material handling.

Crane type | Double Girder Overhead Crane with synchronized hoists |

Model | LH |

Working Class | A3 |

Capacity | 3 ton + 3 ton |

Span length (m) | 9.093 |

Lifting Height(M) | 5.2 m |

Crane control | Pendent control |

Voltage | 400v,50hz,3p |

Color | Gray |

Application | Indoor use |

Crane rail | P22 |

Quantity | 1 |

Synchronized hoist double girder overhead cranes systems is ideal for handling long bulky loads. The customized synchronous lifting of the crane hoist and the accurate leveling of the two load hooks assure efficient, accurate and precise positioning of the lumber such as wood broads without undesirable rotation.

If an overhead crane has two or more cranes hoists, it may be necessary to operate both of them at the same time. When using the hoisting synchronization mode, both the electric hoists run and stop at the same time to keep the load in the same alignment it was in when the hoisting began. Two hoists move at the same speed and in the same direction, both controlled by the same operator interface.The operations of synchromized crane hoists is used in widely used in the automobile and printing industries among other applications.

Features of synchronized hoist overhead cranes for lumber warehouse

- The surface of overhead crane system must be painted with anti-corrosion paint because of the high air salinity on the nearby island. Green electric hoists are acceptable, but light colors like yellow or white should not be used for the paint.

- The overhead crane is set up in a small factory building that already exists. Due to the double girder overhead crane's non-standard size design, production of which must strictly follow the designed drawings.

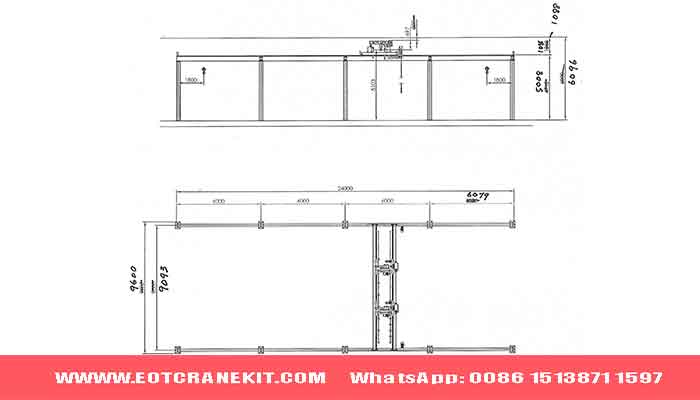

- The layout and bridge crane column are based on the needs of the customer, and the choice of rail-bearing beams and columns is confirmed with the client. For the reserved position of the bolts, pay attention to the direction of the column;

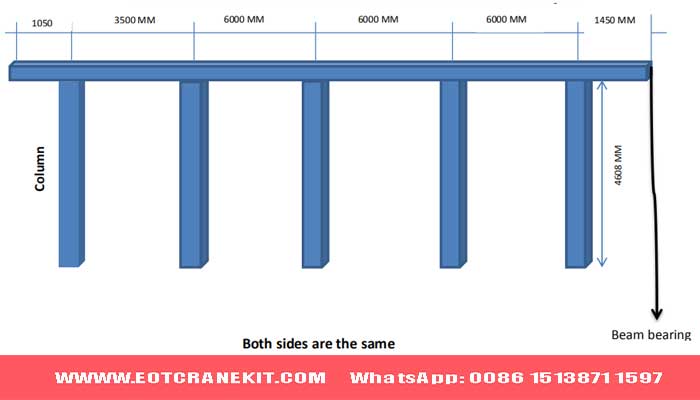

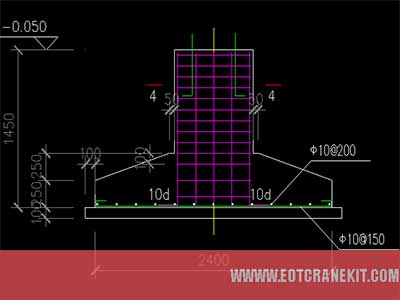

- The column's lifting height is 4303 mm, but because 305 mm of it will be buried underground, the actual production is 4608 mm.

- It is necessary to have a foundation drawing for the crane columns.

- Crane Track - P22, 48m long, with clamp plates and , pressure plate

- Sliding line - seamless sliding line, 8 square centimeter2, 24 meters long , including current collectors and supporting parts.

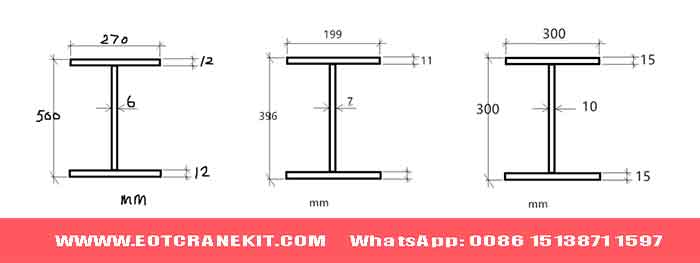

- Runway bearing Beam - H500*270*6*12mm, 72kg/m, 48m

- Column - HW300*300*10*15, about 120kg/ piece, 10 pieces

Details of synchronized hoist overhead crane solutions

Synchronized hoists overhead crane design

Alter the 3 ton + 3 ton synchronized hoist double girder overhead crane's lift height and span to match the supporting column of the crane rail's actual specifications. The head of the Maldive lumber warehouse demands that the overhead bridge crane's lifting height and the distance between the ground and the main beam's lowest point be at least five meters.

The end beam needs to be as short as possible, at least 2796mm, as its length of 4 meters will result in two blind areas of at least two meters on either side of the working area ( based on the designing provided. )

The dimensions should be clearly shown on the drawing, and all parts' sizes, including the total height and length, should be noted.

The workshop's supporting structure is strengthened while also ensuring that the working area is covered as much as possible.

On rail beam specifications

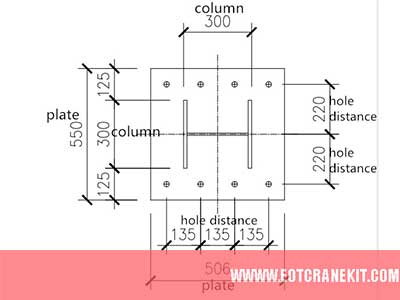

The specifications of H beams, shown as the following picture

Column design adjustment

Is it possible to freely change the direction of the column? Reply: No!

In actuality, the load-bearing is affected by the column's change in direction. The column's size must be increased, and this will result in a significant price increase. (It is acceptable when the price difference is reasonable because the steel weight is much heavier and the thickness of the steel has increased.)

- HN396*199*7*11, 83kg/m

- HW300*300*10*15, the rice weight is about 120kg

Cantilever designs of crane runway and crane column spacing

Columns for your reference

Please keep in mind that the column's extra height will reach through the ground, so don't try to fit the measurement.

The column needs to be lengthened from 4.303 to 4.608 meters, and the extra 305 millimeters must be buried underground to keep the ground level.

On the location of the foundation

The existing supporting wall is made of thin steel plate and It is not appropriate to locate the column foundation outside the wall. The foundation pit's position will be offset to make sure that the entire foundation is inside the wall.

Tips: Because the foundation map is complex, only look at the basics, such as foundation size, bolt hole diameter, and base plate/connection plate thickness.

Crane column foundtion drawings

Specificaitons of crane column foundations

On painting of overhead cranes

- Anti-corrosion – Because the Maldives are an island nation, the air there has a high salinity level. It is necessary to have anti-corrosion paint to ensure synchronized hoist crane's working life.

- Color Preferences / Taboos / Obstacles -The color of the paint should not be a light color such as yellow, but rather gray, which is the customer's preference and can be met.

Productions of synchronized hoists overhead cranes

Main girder of double girder overhead crane under construction

Crane columns

Duel hoist trolley for the synchronized hoist crane system

Main girder painted of the double girder overhead crane

Packagings and delivery of duel hoists overhead cranes

Loaded into container for delivery

Packed and delivery of double girder overhead crane

Packing dimensions

Dimensions of packed main parts and components of synchronized hoist double girder overhead cranes are presented for your refernece .

Item | Quantity | Serial number | Length of Unit | Width of Unit | Height of Unit | Weight of Unit | Volumnecbm | Gross Weight | Net Weight |

Main girder | 1 | 1 | 9.25 | 0.64 | 0.9 | 840 | 5.328 | 840 | 840 |

Main girder | 1 | 2 | 9.25 | 0.6 | 0.64 | 740 | 3.552 | 740 | 740 |

End carriages | 2 | 3-4 | 2.65 | 0.17 | 0.15 | 102 | 0.13515 | 204 | 204 |

Hoist trolley | 2 | 5-6 | 1.68 | 1.13 | 0.6 | 370 | 2.27808 | 740 | 740 |

Parts and components case | 1 | 7 | 0.9 | 0.9 | 0.85 | 220 | 0.6885 | 220 | 180 |

Column | 6 | 8-13 | 4.61 | 0.5 | 0.5 | 502 | 6.915 | 3012 | 3012 |

Column | 4 | 14-17 | 4.61 | 0.5 | 0.62 | 512 | 5.7164 | 2048 | 2048 |

Runway beam | 2 | 18-19 | 4.55 | 0.27 | 0.5 | 388 | 1.2285 | 776 | 776 |

Runway beam | 4 | 20-23 | 6 | 0.27 | 0.5 | 490 | 3.24 | 1960 | 1960 |

Runway beam | 2 | 24-25 | 7.45 | 0.27 | 0.5 | 610 | 2.0115 | 1220 | 1220 |

Columns bracing | 2 | 26-27 | 6.9 | 0.26 | 0.1 | 68 | 0.3588 | 136 | 136 |

Columns bracing | 4 | 28-31 | 3.4 | 0.26 | 0.1 | 33 | 0.3536 | 132 | 132 |

Crane stops | 4 | 32-35 | 0.41 | 0.35 | 0.2 | 18 | 0.1148 | 72 | 72 |

40m P22 crane rail | 6 | / | 8 | 0.095 | 0.095 | 170 | 0.4332 | 1020 | 1020 |

Bolts, clamps | 1 | 36 | 0.78 | 0.53 | 0.49 | 312 | 0.202566 | 312 | 280 |

Walking platform | 1 | 37 | 6.05 | 0.2 | 0.95 | 35 | 1.1495 | 35 | 35 |

43 units | 33.71cbm | 13467kgs | 13395kgs | ||||||

NO of Container :1*40GP | |||||||||

Item | Quantity | Serial number | Length of Unit | Width of Unit | Height of Unit | Weight of Unit | Volume | Gross Weight | Net Weight |

Main girder | 1 | 1 | 9.25 | 0.64 | 0.9 | 840 | 5.328 | 840 | 840 |

Main girder | 1 | 2 | 9.25 | 0.6 | 0.64 | 740 | 3.552 | 740 | 740 |

End carriages | 2 | 3-4 | 2.65 | 0.17 | 0.15 | 102 | 0.13515 | 204 | 204 |

Runway beam | 4 | 20-23 | 6 | 0.27 | 0.5 | 490 | 3.24 | 1960 | 1960 |

Runway beam | 2 | 24-25 | 7.45 | 0.27 | 0.5 | 610 | 2.0115 | 1220 | 1220 |

Column bracing | 2 | 26-27 | 6.9 | 0.26 | 0.1 | 68 | 0.3588 | 136 | 136 |

48mP22crane rail | 6 | / | 8 | 0.095 | 0.095 | 170 | 0.4332 | 1020 | 1020 |

Accessories cases | 1 | 7 | 0.9 | 0.9 | 0.85 | 220 | 0.6885 | 220 | 180 |

Bolts & clamps cases | 1 | 36 | 0.78 | 0.53 | 0.49 | 312 | 0.202566 | 312 | 280 |

Walking platform | 1 | 37 | 6.05 | 0.2 | 0.95 | 35 | 1.1495 | 35 | 35 |

21 units | 17.1cbm | 6687kgs | 6615kgs | ||||||

NO of Container:1*20GP | |||||||||

Items | Quantity | Serial number | Length of Unit | Width of Unit | Height of Unit | Weight of Unit | Volume | Gross Weight | Net Weight |

Crane trolley | 2 | 5-6 | 1.68 | 1.13 | 0.6 | 370 | 2.27808 | 740 | 740 |

Column | 6 | 8-13 | 4.61 | 0.5 | 0.5 | 502 | 6.915 | 3012 | 3012 |

Column | 4 | 14-17 | 4.61 | 0.5 | 0.62 | 512 | 5.7164 | 2048 | 2048 |

Runway beam | 2 | 18-19 | 4.55 | 0.27 | 0.5 | 388 | 1.2285 | 776 | 776 |

Column bracing | 4 | 28-31 | 3.4 | 0.26 | 0.1 | 33 | 0.3536 | 132 | 132 |

Crane stop | 4 | 32-35 | 0.41 | 0.35 | 0.2 | 18 | 0.1148 | 72 | 72 |

22 units | 16.61cbm | 6780kgs | 6780kgs |

Feedback of overhead synchronized hoist crane systems

Feedback video of synchronized hoist cranes system for lumber warehouse are presned for your reference: