Hook Crane Block, Hook blocks Pulley & Crane Bottom Blocks

Hook Crane blocks, crane bottom blocks & Hook blocks pulley are below-the-hook lifting devices & lifting equipment which can be customized on capacity & your specific application.

Category: Below Hook Devices

Your Trusted Overhead Crane Kit Manufacturer & Supplier

Hook Crane Block, Hook blocks Pulley & Crane Bottom Blocks

Hook crane blocks, crane bottom blocks & Hook blocks pulley are below-the-hook lifting devices & lifting equipment which can be customized on capacity & your specific application. To optimize the performance of your industrial lifting equipment, you can incorporate sheave configuration, capacity, special control requirements, and unique reeving patterns.

What is hook blocks?

What is crane hook blocks? Hook blocks for overhead cranes, gantry cranes, and other lifting equipment are available for order. There are many types of crane hook blocks available, with different hook block dimension. Hook block design service is available. Check out the different varieties of crane hook blocks and get free crane bottom block design drawing for free.

Crane hook blocks is a common below hook devices for grabbing and lifting loads used by lifting hoist or overhead crane. The lifting hook blocks is usually equipped with hook safety latch to ensure the wire rope sling or chain sling in the proper place of hook blocks and ensure the hoist and overhead crane safety. With one or more built-in pulleys, the hook blocks group can amplify the lifting force.

Components of hook group

Crane hook pulley is usually consisted of the hook, hook nut, thrust bearing, hook beams, pulley, pulley bearings, pulley hanger, and other components of the crane hook group, etc.

Application of hook group

Crane hook group is frequently used to handle materials because of its simple construction and high usability. Crane hook groups, being the most extensively used load handling devices, are typically utilized with types of crane machinery to handle items in a variety of applications in various industries.

Types of crane hook blocks & crane bottom blocks

According to different standards, hook blocks can be classified into different types, the single hook blocks and double hook blocks, the forging hook blocks and laminated hook blocks, closed hook blocks and semi-closed hook blocks, and other hooks, such as, electric rotary hook blocks, etc. according to the different features, these types of Hook blocks are widely used in different applications.

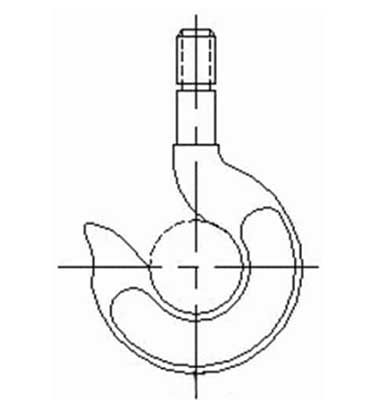

Forged single hook

Laminated double hook

Single hook blocks & double hook blocks

Hook blocks can be classified in to single crane hook blocks, and double hook blocks, etc.

Single hook blocks

Single hook blocks are typically used to handle loads weighing less than 75 tons, and have the advantages of being simple to manufacture and utilize.

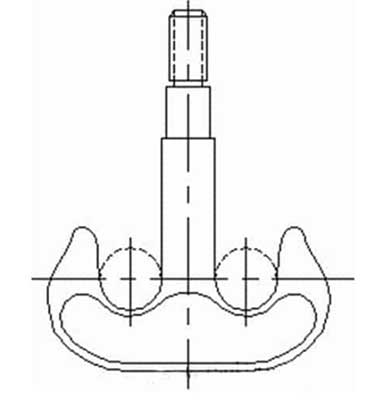

Double hook blocks

The double hook blocks are commonly utilized for large load management due to their high bearing capacity.

Forging hook blocks & Laminated hook blocks

Hook blocks are divided into two types based on their manufacturing methods: forging crane hook blocks and laminated hook blocks.

Forged double hook

Laminated double hook

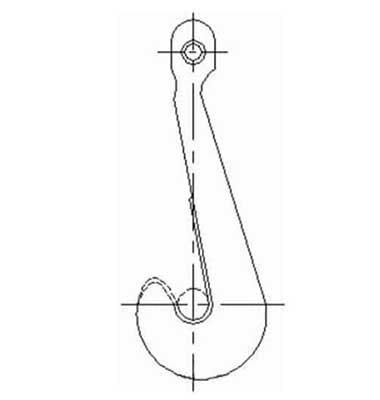

Forging hook blocks

Forge hook - Hook blocks are forged from high-quality low-carbon steel or low-carbon alloy steel, such as 20 high-quality low-carbon steel, 16Mn, 20MnSi, and 36MnSi, which are then annealed.

Although the forging hook is simple to build and operate, its stress condition is inferior to that of a laminated hook. As a result, the forging hook is often utilized for loads under 80 tons. When it comes to carrying hefty loads, double hooks will be used.

Laminated Hook blocks

Laminated Hook are riveted together using numerous steel plates. When one of the plates on the laminated hook has a flaw, the entire hook can still perform without being destroyed. Laminated hooks are commonly employed on heavy lifting capacity cranes, such as steel ladle cranes, due to their high safety and enormous dead weight.Single laminated hooks and double laminated hooks are two types of laminated hooks.

Laminated Hook blocks / ladle Hook blocks- Types of Hook blocks of Dongqi

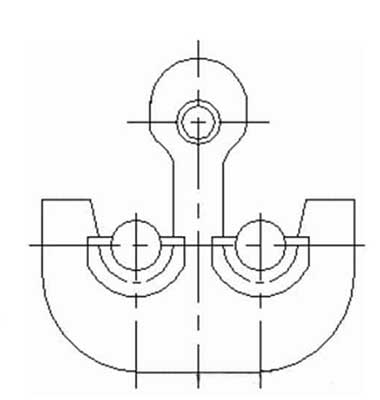

Closed hook blocks and semi-closed hook blocks

You can choose between closed and semi-closed Hook blocks if you're concerned about having the proper hook attachments. These distinct types of hooks have an attachment for increased security when carrying heavy loads; the attachment can be closed or semi-closed, as the name implies.

Semi closed crane hook blocks

Closed hook blocks

Closed Hook blocks

Closed Hook blocks attachments are a little more challenging to use and is a little time-consuming but they provide the maximum level of safety and load bearing potential.

Semi-Closed Hook blocks

They strive to fill the gap by providing higher degrees of security than regular lifting hooks while being easier to connect and detach than closed hooks.

Closed and semi-closed Hook blocks- Types of cranes hooks of Dongqi

Featured hook blocks

Hook blocks blocks, crane bottom blocks & Hook blocks pulley are below-the-hook lifting devices & lifting equipment which can be customized on capacity & your specific application. Sheave configuration, capacity, special control requirements and unique reeving patterns can be incorporated to improve your industrial lifting equipment operation.

Electric rotary Hook blocks

If you demand cutting-edge Hook blocks with the best features and the most convenience, you will most likely have to choose between electric rotary hooks and other forms of modern Hook blocks.

When lifting containers, an electric rotating hook is a smart piece of below-the-hook lifting equipment that will improve the crane's manoeuvrability and effectiveness. These crane hooks have the capacity to rotate while maintaining a strong grip on the cargo, making them particularly useful and productive in instances when a large number of containers must be moved in a small area of land.

Crane hooks

Customized crane hook blocks

Customized crane bottom hooks

Hoisting crane

Hook blocks design service

As a well known crane parts manufacturer and supplier, with powerful crane designing team, we are able to provide Hook blocks design services to produce types of specialized hook blocks to meet the needs of various crane manufacturers and for crane end users. Due to the characteristics of simple manufacture and strong usability, our hook pulley group is used widely to handle materials with overhead crane, gantry crane,jib crane, and electric hoists, etc.

Hook block groups, being the most extensively used load handling devices, are typically utilized with hoist or crane equipment to handle good loads in a variety of applications in many industries. Please contact us if you require unique hook blocks for your overhead crane, gantry crane, or other types of crane.

Single hook blocks are typically used to handle loads weighing less than 75 tons, and have the advantages of being simple to manufacture and utilize.

The double hook blocks are commonly utilized for large load management due to their high bearing capacity.

Hook blocks are forged from high-quality low-carbon steel or low-carbon alloy steel, such as 20 high-quality low-carbon steel, 16Mn, 20MnSi, and 36MnSi, which are then annealed.

Laminated Hook blocks are riveted together using numerous steel plates.

Hook blocks maintenance

The procedures of hook blocks maintenance:

- Disassemble all of the Hook blocks, including the head, shaft, beam, pulley block, and bearings, inspect their condition, and clean and lubricate as needed.

- Examine the dangerous cross section's wear state.

- Put the hook blocks to the test.

- Examine the state of the Hook blocks plate.

How to check the cracks of crane hook blocks?

- Hook blocks, beams, and pulley blocks are not allowed to be cracked. The screw will not loosen. The bearing must be in good working order. If you notice a cutter mark or a crack on the tool escape, rotate the pulley and replace it.

- If the hazardous cross section has worn down by more than 10% from its original height, it should be replaced.

- The Hook blocks must be tested and checked after they have been repaired. The mouth of Hook blocks should be opened less than 0.25 percent compared to the original size while hanging the 1.25 maltaple weight compared to lifting ability in 10 minutes. Deformation and cracking are not permitted after unloading.

- The gap between the plates after riveting for the Hook blocks plate should be smaller than 0.3 mm.

FAQs of Crane hook blocks & Crane bottom blocks

Hook blocks FAQ 1.What is the material of Hook blocks?

Hook blocks are often made of DG20 steel and DG34GrMo alloy steel that has been forged, pressed, annealed, and machined with the features of high strength, plasticity, and toughnes.

Flaps are commonly employed in applications with high tonnage and high temperatures.

The hook is often built of A3, 20, or 16Mn steel plates with a minimum thickness of 20mm, great reliability, and no unexpected fracture.

When a hook breaks or cracks, it must be destroyed and replaced with hook accessories from the original manufacturer. If not, the new hook accessories should be identical to the original in terms of hook material, grade, and specification to avoid different accidents caused by the electric chain hoist's mismatch.

Hook blocks FAQ 2.Hook blocks rotation causes and preventive measures

Hook blocks twisting is often happened without any warning during lifting motion. Under loading, hook blocks and the wire ropes between hook and pulley twisted together, then the lifting operation have to be stopped. Hook blocks rotation can affect hoisting operation,and threaten the safety of workers and equipment seriously, which must be avoided.

Hook blocks rotation causes

Hook block rotation is caused by a combination of internal and external crane forces. The internal cause of its occurrence is, in fact, the root cause.

Internal factors to Hook blocks rotation

Crane wire rope will provide torque in the force regardless of model, specs, or grades. Torque is created during the wire rope production process, in which wires are twisted together to form a strand, and then numerous strands are twisted together to form a rope. When a force is applied to the rope, the wire and strands straighten, but the wire rope's end is fixed, resulting in a torque in the wire rope.

External factors to Hook blocks rotations

On the other hand, various external forces, such as human or wind force during the hoisting operation, directly cause the hook to rotate.

Because the crane operator is not moving the crane steadily, the hook and weight swing create hook rotation, unbalance, and other problems.

Preventive measures to Hook blocks rotations

To avoid hook blocks rotation, the crane should be moved steadily and smoothly, the hook should be located in the center of the lifting material, the wire rope should be straightened before lifting the material, and the wire rope should be re-fixed yearly to ensure it is free and without force when there is no load.

Note: When there is twisting in the wire rope, the lifting motion should be halted immediately; otherwise, the crane may be damaged, and adjacent workers may be at risk.

Hook blocks FAQ 3. Why can't the hoist hook to be repaired by welding?

Because the hook must be fixed by welding, it is difficult to adhere to quality requirements, as the entire process involves melting, fusion, and curing, among other things.

During repair, the basic section of the hook is influenced by heating and cooling effects of various degrees due to the heat transfer impact, exactly as heat treatment resulted in modifications of formation and essence. Furthermore, welding is typically performed on the hook's wear and sag points, which are in a straight line with the vertical critical section.

Welding ruins the hook's metal structure and metal fiber sequence, as well as the hook's toughness, lowering the hook's performance and hurting the electric chain hoist's performance.

Hook blocks FAQ 4. Hook blocks supervision and inspection

The quality of the lifting hook is directly related to the safety of people and property. Hook blocks are a very important form of lifting device that has played an essential part in types of cranes and hoists. The hook quality control and hook inspection should be enhanced to prevent hook fracture failure accidents.

Supervision of new hooks entering the factory

- Examine the hook's material certificate, heat treatment report, and other quality assurance documentation, and demand the manufacturing plant to follow GB 10051-1988 to the letter, with the raw materials for the Hook blocks being one of the five materials specified in the standard.

- Ensure that the hook's surface is smooth and free of cracks, sharp angles, burrs, peeling, and other faults; the hook should be free of cracks, white spots, and inclusions.

Measure the hook's original shape and weight and keep it on hand for the next examination.

Inspections in use of hooks

- Non-destructive testing must be performed on the portions that are subjected to the most stress. When cracks are discovered, the Hook blocks should be promptly removed from service and replaced with a new lifting hook.

- The dangerous area of the hook should be inspected for abrasion or corrosion on a regular basis. Hook blocks should be replaced when the actual size of the lifting hook is less than 95% of the original size.

- Hook blocks should be replaced when the distortion of the hook opening reaches 15% of its original size.

- The lifting hook is not authorized to be welded.

- Plastic deformation in a dangerous area or hook handle is prohibited.

- Lifting hook is a common wear component and accessory in machinery factories, and once fracture and fall accidents occur, they can easily cause serious person and equipment accidents. As a result, pay extra attention to the safety of Hook blocks, quality control, and regular inspection.

- Hook blocks testing and measuring, Hook blocks and hoist hook fabrication and supplying

Hook blocks FAQ 5. When the Hook blocks should be stopped in use?

The lifting hook is an essential component of an electric hoist. The fatigue crack may arise due to the heavy loading in the usage of hoisting, and hoist inspection is required at least once or twice a year, as well as regular annealing treatment, to ensure the safety of operation and to extend the life of the hook.

In the following cases, the hook to be discarded and replaced:

- 1. Examine the surface of the hook with a 20x magnifying glass; any cracked or damaged hooks should be replaced.

- 2. When the crucial area of the hook is worn more than 10%, it can no longer be used.

- 3. If permanent deformation develops during loading testing, the hook should be replaced.

- 4. When the hook's end or thread component has cracks or deformation, it should be changed.

- 5. If the transition corner of the hook end develops fatigue cracks, the hook should be replaced.

Hook crane blocks, crane bottom blocks & Hook blocks pulley are below-the-hook lifting devices & lifting equipment which can be customized on capacity & your specific application. To optimize the performance of your industrial lifting equipment, you can incorporate sheave configuration, capacity, special control requirements, and unique reeving patterns.

What is crane hook blocks? Hook blocks for overhead cranes, gantry cranes, and other lifting equipment are available for order. There are many types of crane hook blocks available, with different hook block dimension. Hook block design service is available. Check out the different varieties of crane hook blocks and get free crane bottom block design drawing for free.

Crane hook blocks is a common below hook devices for grabbing and lifting loads used by lifting hoist or overhead crane. The lifting hook blocks is usually equipped with hook safety latch to ensure the wire rope sling or chain sling in the proper place of hook blocks and ensure the hoist and overhead crane safety. With one or more built-in pulleys, the hook blocks group can amplify the lifting force.

Types of crane hook blocks & crane bottom blocks

According to different standards, hook blocks can be classified into different types, the single hook blocks and double hook blocks, the forging hook blocks and laminated hook blocks, closed hook blocks and semi-closed hook blocks, and other hooks, such as, electric rotary hook blocks, etc. according to the different features, these types of Hook blocks are widely used in different applications.

Single hook blocks & double hook blocks

Hook blocks can be classified in to single crane hook blocks, and double hook blocks, etc.

Single hook blocks

Single hook blocks are typically used to handle loads weighing less than 75 tons, and have the advantages of being simple to manufacture and utilize.

Double hook blocks

The double hook blocks are commonly utilized for large load management due to their high bearing capacity.

Forging hook blocks & Laminated hook blocks

Hook blocks are divided into two types based on their manufacturing methods: forging crane hook blocks and laminated hook blocks.

Forging hook blocks

Forge hook - Hook blocks are forged from high-quality low-carbon steel or low-carbon alloy steel, such as 20 high-quality low-carbon steel, 16Mn, 20MnSi, and 36MnSi, which are then annealed.

Although the forging hook is simple to build and operate, its stress condition is inferior to that of a laminated hook. As a result, the forging hook is often utilized for loads under 80 tons. When it comes to carrying hefty loads, double hooks will be used.

Laminated Hook blocks

Laminated Hook blocks are riveted together using numerous steel plates. When one of the plates on the laminated hook has a flaw, the entire hook can still perform without being destroyed. Laminated hooks are commonly employed on heavy lifting capacity cranes, such as steel ladle cranes, due to their high safety and enormous dead weight.Single laminated hooks and double laminated hooks are two types of laminated hooks.

Laminated Hook blocks / ladle Hook blocks- Types of Hook blocks of Dongqi

Closed hook blocks and semi-closed hook blocks

You can choose between closed and semi-closed Hook blocks if you're concerned about having the proper hook attachments. These distinct types of hooks have an attachment for increased security when carrying heavy loads; the attachment can be closed or semi-closed, as the name implies.

Closed Hook blocks

Closed Hook blocks attachments are a little more challenging to use and is a little time-consuming but they provide the maximum level of safety and load bearing potential.

Semi-Closed Hook blocks

They strive to fill the gap by providing higher degrees of security than regular lifting hooks while being easier to connect and detach than closed hooks.

Closed and semi-closed Hook blocks- Types of cranes hooks of Dongqi

Featured hook blocks

Hook blocks blocks, crane bottom blocks & Hook blocks pulley are below-the-hook lifting devices & lifting equipment which can be customized on capacity & your specific application. Sheave configuration, capacity, special control requirements and unique reeving patterns can be incorporated to improve your industrial lifting equipment operation.

Electric rotary Hook blocks

If you demand cutting-edge Hook blocks with the best features and the most convenience, you will most likely have to choose between electric rotary hooks and other forms of modern Hook blocks.

When lifting containers, an electric rotating hook is a smart piece of below-the-hook lifting equipment that will improve the crane's manoeuvrability and effectiveness. These crane hooks have the capacity to rotate while maintaining a strong grip on the cargo, making them particularly useful and productive in instances when a large number of containers must be moved in a small area of land.

Electric rotary hook - Dongqi electric Hook blocks

Other types of Hook blocks

Hook blocks design service

As a well known crane parts manufacturer and supplier, with powerful crane designing team, we are able to provide Hook blocks design services to produce types of specialized hook blocks to meet the needs of various crane manufacturers and for crane end users. Due to the characteristics of simple manufacture and strong usability, our hook pulley group is used widely to handle materials with overhead crane, gantry crane,jib crane, and electric hoists, etc.

Hook block groups, being the most extensively used load handling devices, are typically utilized with hoist or crane equipment to handle good loads in a variety of applications in many industries. Please contact us if you require unique hook blocks for your overhead crane, gantry crane, or other types of crane.

Hook blocks maintenance

The procedures of hook blocks maintenance:

- Disassemble all of the Hook blocks, including the head, shaft, beam, pulley block, and bearings, inspect their condition, and clean and lubricate as needed.

- Examine the dangerous cross section's wear state.

- Put the hook blocks to the test.

- Examine the state of the Hook blocks plate.

How to check the cracks of crane hook blocks?

- Hook blocks, beams, and pulley blocks are not allowed to be cracked. The screw will not loosen. The bearing must be in good working order. If you notice a cutter mark or a crack on the tool escape, rotate the pulley and replace it.

- If the hazardous cross section has worn down by more than 10% from its original height, it should be replaced.

- The Hook blocks must be tested and checked after they have been repaired. The mouth of Hook blocks should be opened less than 0.25 percent compared to the original size while hanging the 1.25 maltaple weight compared to lifting ability in 10 minutes. Deformation and cracking are not permitted after unloading.

- The gap between the plates after riveting for the Hook blocks plate should be smaller than 0.3 mm.

FAQs of Crane hook blocks & Crane bottom blocks

Hook blocks FAQ 1.What is the material of Hook blocks?

Hook blocks are often made of DG20 steel and DG34GrMo alloy steel that has been forged, pressed, annealed, and machined with the features of high strength, plasticity, and toughnes.

Flaps are commonly employed in applications with high tonnage and high temperatures.

The hook is often built of A3, 20, or 16Mn steel plates with a minimum thickness of 20mm, great reliability, and no unexpected fracture.

When a hook breaks or cracks, it must be destroyed and replaced with hook accessories from the original manufacturer. If not, the new hook accessories should be identical to the original in terms of hook material, grade, and specification to avoid different accidents caused by the electric chain hoist's mismatch.

Hook blocks FAQ 2.Hook blocks rotation causes and preventive measures

Hook blocks twisting is often happened without any warning during lifting motion. Under loading, hook blocks and the wire ropes between hook and pulley twisted together, then the lifting operation have to be stopped. Hook blocks rotation can affect hoisting operation,and threaten the safety of workers and equipment seriously, which must be avoided.

Hook blocks rotation causes

Hook block rotation is caused by a combination of internal and external crane forces. The internal cause of its occurrence is, in fact, the root cause.

Internal factors to Hook blocks rotation

Crane wire rope will provide torque in the force regardless of model, specs, or grades. Torque is created during the wire rope production process, in which wires are twisted together to form a strand, and then numerous strands are twisted together to form a rope. When a force is applied to the rope, the wire and strands straighten, but the wire rope's end is fixed, resulting in a torque in the wire rope.

External factors to Hook blocks rotations

On the other hand, various external forces, such as human or wind force during the hoisting operation, directly cause the hook to rotate.

Because the crane operator is not moving the crane steadily, the hook and weight swing create hook rotation, unbalance, and other problems.

Preventive measures to Hook blocks rotations

To avoid hook blocks rotation, the crane should be moved steadily and smoothly, the hook should be located in the center of the lifting material, the wire rope should be straightened before lifting the material, and the wire rope should be re-fixed yearly to ensure it is free and without force when there is no load.

Note: When there is twisting in the wire rope, the lifting motion should be halted immediately; otherwise, the crane may be damaged, and adjacent workers may be at risk.

Hook blocks FAQ 3. Why can't the hoist hook to be repaired by welding?

Because the hook must be fixed by welding, it is difficult to adhere to quality requirements, as the entire process involves melting, fusion, and curing, among other things.

During repair, the basic section of the hook is influenced by heating and cooling effects of various degrees due to the heat transfer impact, exactly as heat treatment resulted in modifications of formation and essence. Furthermore, welding is typically performed on the hook's wear and sag points, which are in a straight line with the vertical critical section.

Welding ruins the hook's metal structure and metal fiber sequence, as well as the hook's toughness, lowering the hook's performance and hurting the electric chain hoist's performance.

Hook blocks FAQ 4. Hook blocks supervision and inspection

The quality of the lifting hook is directly related to the safety of people and property. Hook blocks are a very important form of lifting device that has played an essential part in types of cranes and hoists. The hook quality control and hook inspection should be enhanced to prevent hook fracture failure accidents.

Supervision of new hooks entering the factory

- Examine the hook's material certificate, heat treatment report, and other quality assurance documentation, and demand the manufacturing plant to follow GB 10051-1988 to the letter, with the raw materials for the Hook blocks being one of the five materials specified in the standard.

- Ensure that the hook's surface is smooth and free of cracks, sharp angles, burrs, peeling, and other faults; the hook should be free of cracks, white spots, and inclusions.

Measure the hook's original shape and weight and keep it on hand for the next examination.

Inspections in use of hooks

- Non-destructive testing must be performed on the portions that are subjected to the most stress. When cracks are discovered, the Hook blocks should be promptly removed from service and replaced with a new lifting hook.

- The dangerous area of the hook should be inspected for abrasion or corrosion on a regular basis. Hook blocks should be replaced when the actual size of the lifting hook is less than 95% of the original size.

- Hook blocks should be replaced when the distortion of the hook opening reaches 15% of its original size.

- The lifting hook is not authorized to be welded.

- Plastic deformation in a dangerous area or hook handle is prohibited.

- Lifting hook is a common wear component and accessory in machinery factories, and once fracture and fall accidents occur, they can easily cause serious person and equipment accidents. As a result, pay extra attention to the safety of Hook blocks, quality control, and regular inspection.

- Hook blocks testing and measuring, Hook blocks and hoist hook fabrication and supplying

Hook blocks FAQ 5. When the Hook blocks should be stopped in use?

The lifting hook is an essential component of an electric hoist. The fatigue crack may arise due to the heavy loading in the usage of hoisting, and hoist inspection is required at least once or twice a year, as well as regular annealing treatment, to ensure the safety of operation and to extend the life of the hook.

In the following cases, the hook to be discarded and replaced:

- 1. Examine the surface of the hook with a 20x magnifying glass; any cracked or damaged hooks should be replaced.

- 2. When the crucial area of the hook is worn more than 10%, it can no longer be used.

- 3. If permanent deformation develops during loading testing, the hook should be replaced.

- 4. When the hook's end or thread component has cracks or deformation, it should be changed.

- 5. If the transition corner of the hook end develops fatigue cracks, the hook should be replaced.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch