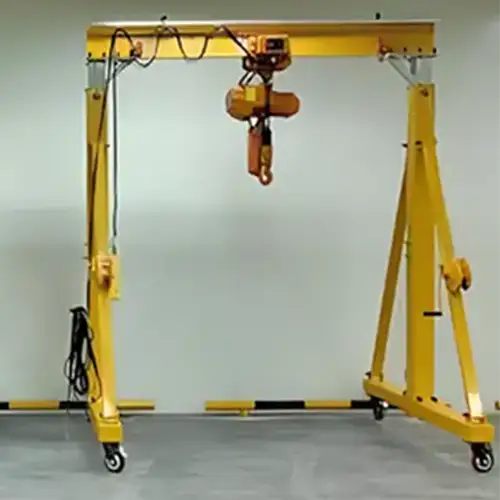

Adjustable Gantry Crane 3Ton for Auto Parts Handling

3 ton adjustable gantry crane for auto parts lifting. 3 ton gantry crane tailored for workshop needing mobility, reliability & cost-effective lifting.

Category: 3 Ton Gantry Cranes

Your Trusted Overhead Gantry Crane Manufacturer & Supplier

3 Ton Adjustable Gantry Crane for Sale

Adjustable 3Ton Gantry Crane for Auto Parts Handling

Efficient and versatile 3-ton adjustable gantry crane for safe auto parts lifting. Ideal for workshops needing mobility, reliability, and cost-effective operation.

In a busy auto parts manufacturing plant, lifting and moving components like engines, transmissions, and chassis parts is part of the daily routine. These items differ in weight and size, which makes handling them safely a constant challenge. Manual lifting slows production and increases the risk of damage or injury.

The plant needed a solution that could:

- Lift medium-weight parts up to 3 tons.

- Adapt to different heights with a range of 1.85 to 3.7 meters.

- Fit in limited spaces, such as narrow aisles and between assembly stations.

- Work reliably with the plant’s electricity supply (220V, 60Hz, 3-phase).

After reviewing options, the team selected a 3-ton adjustable gantry crane. Its adjustable span of 2.5 meters and easy mobility made it a practical choice. Operators can lift, move, and position auto parts safely and efficiently without waiting for forklifts or other equipment.

The purpose of this case study is simple: to show how this crane improves workflow, enhances safety, and supports daily operations. We’ll explore how it handles a variety of auto parts, fits the plant layout, and makes day-to-day lifting tasks smoother and more predictable.

Project Background

The auto parts plant covers a medium-sized facility of roughly 5,000 square meters, with multiple assembly lines, storage racks, and testing areas. Space is tight in some sections, especially around assembly stations and narrow aisles between racks. Parts need to move quickly from storage to production without causing bottlenecks, so the workflow demands a lifting solution that is both flexible and reliable.

Types of Auto Parts Handled

The plant deals with a wide variety of components, each with its own handling requirements:

- Engines – heavy and bulky, requiring careful lifting to avoid damage.

- Gearboxes – medium-weight, irregular shape, and sensitive to impact.

- Chassis components – long, sometimes awkward pieces that need precise positioning.

- Suspension parts, steering systems, and smaller assemblies – frequent, repetitive lifts throughout the day.

The variety in size and weight means a single lifting method often isn’t enough. Operators need a crane that can handle multiple types of components safely and efficiently.

Previous Lifting Solutions and Limitations

Before adopting the adjustable gantry crane, the plant relied on a mix of manual handling, forklifts, and fixed overhead cranes. Each method had its drawbacks:

- Manual handling – increased the risk of worker injury and limited the ability to lift heavier parts.

- Forklifts – required wide aisles and careful maneuvering, slowing down production in tight spaces.

- Fixed overhead cranes – limited mobility and height adjustments; could not serve multiple stations without significant reconfiguration.

The combination of these limitations led the team to look for a solution that could handle medium-weight parts, adjust to different heights, and move easily across the workshop without disrupting production.

Crane Selection Criteria

Choosing the right lifting equipment for the auto parts plant required careful consideration. The crane had to fit within a busy workshop, handle a range of components safely, and provide flexibility for daily operations.

Lifting Capacity

The primary requirement was a lifting capacity of 3 tons. This covers most engines, gearboxes, and chassis components handled in the plant without the need for multiple cranes or excessive manual intervention. Operators can lift heavier parts confidently, reducing the risk of accidents.

Adjustable Height

Flexibility in height was essential. The crane needed an adjustable range from 1.85 to 3.7 meters, allowing it to:

- Reach storage racks at different levels.

- Lift parts over assembly tables or workstations.

- Adapt to temporary changes in production layout without additional equipment.

Adjustable Span

A span of 2.5 meters was chosen to match the width of assembly stations and narrow aisles. This ensures the crane can move parts efficiently across the workspace while maintaining stability during lifts.

Electrical Requirements

The plant operates on a 220V, 60Hz, 3-phase power supply, so the crane had to be compatible without requiring costly electrical modifications. This allowed for quick installation and seamless integration into the existing infrastructure.

Safety and Standards Compliance

Safety was a top priority. The crane needed:

- Overload protection to prevent lifting beyond capacity.

- Emergency stop functions for operator safety.

- Compliance with CE or ISO standards, ensuring reliability and adherence to international safety norms.

Mobility Options

The crane also had to be flexible in movement. Options considered included:

- Manual travel – simple and cost-effective for short moves between workstations.

- Motorized travel – faster and easier for moving heavier parts over longer distances or frequent transfers.

Workflow Compatibility

Finally, the crane had to integrate smoothly with the plant's workflow:

- Fit within narrow aisles without blocking operations.

- Serve multiple workstations without requiring constant relocation.

- Allow operators to adjust height and span quickly, minimizing downtime.

By addressing these criteria, the plant ensured the chosen 3-ton adjustable gantry crane would not only lift parts safely but also improve efficiency and flexibility in day-to-day operations.

Crane Specifications

The adjustable 3-ton gantry crane provides flexibility, safety, and efficiency for daily operations in the auto parts plant. Its design fits tight spaces and adapts to various lifting needs.

Key Specifications:

- Model: Adjustable Gantry Crane

- Lifting Capacity: 3 Tons – ideal for engines, gearboxes, and chassis components.

- Adjustable Span: 2.5 m – suits narrow aisles and multiple workstations.

- Height Range (H): 1.85–3.7 m – easy adjustment for different storage and workstation heights.

- Power Supply: 220V, 60Hz, 3-phase – compatible with standard plant electricity.

- Travel Options: Manual wheels / Optional motorized – flexible for short or frequent moves.

- Construction: Steel frame with anti-corrosion coating – durable for daily industrial use.

- Safety Features: Overload protection, emergency stop, and locking pins for height security.

- Mobility: Quick assembly and relocation – ideal for changing workshop layouts.

This compact setup ensures safe, efficient, and flexible lifting for a variety of auto parts, streamlining workflow without requiring extra equipment.

Operational Performance

The adjustable 3 ton gantry crane has proven highly effective in daily operations at the auto parts plant.

Types of Parts Handled

- Engines and gearboxes: 200–800 kg, lifted multiple times per shift.

- Chassis components: 300–500 kg, moved frequently between assembly stations.

- Suspension and smaller parts: 50–200 kg, repetitive lifts throughout the day.

Ease of Adjustment

- Height can be quickly changed between 1.85–3.7 m, allowing operators to lift parts over racks, tables, or conveyors.

- The 2.5 m adjustable span lets the crane reach different workstations without repositioning the base.

Productivity Gains

- Lifts are faster and smoother compared to manual handling or forklifts.

- Time per lift reduced by 30–40%, helping assembly lines maintain steady throughput.

- Fewer interruptions as the crane can serve multiple stations efficiently.

Client Feedback

Operators and supervisors at the plant report positive experiences with the 3-ton adjustable gantry crane.

- Ease of Use: Simple to maneuver and adjust, even in narrow aisles.

- Flexibility & Reliability: Adjustable height and 2.5 m span handle multiple parts types; operates smoothly with minimal issues.

- Maintenance: Routine checks are easy, spare parts readily available, and downtime is low.

Overall, the crane is praised for improving workflow, safety, and day-to-day efficiency in the plant.

Benefits & Outcomes

The introduction of the 3-ton adjustable gantry crane has brought clear improvements to workshop operations. Tasks that previously required manual effort or forklifts are now faster, safer, and more predictable. The crane’s design allows operators to handle a wide range of parts without constantly repositioning equipment.

Key benefits include:

- Operational Efficiency: Faster lifts, less downtime, and multi-station coverage without moving the base.

- Worker Safety: Overload protection, emergency stop, and stable lifting reduce injury risks.

- Flexibility: Adjustable height (1.85–3.7 m) and span (2.5 m) handle engines, gearboxes, chassis parts, and smaller assemblies.

- Cost-Effective: Low maintenance, easy relocation, and fewer additional lifting tools needed.

Conclusion

The 3-ton adjustable gantry crane successfully meets the plant’s lifting requirements, improving workflow while keeping workers safe. It integrates well into the workshop layout and adapts to various parts and production stations, making it a practical everyday tool.

Takeaways and recommendations:

- Recommendation: Ideal for small-to-medium auto parts plants with limited space and varied lifting tasks.

- Future Upgrades: Motorized travel, higher spans, or automation for faster and repetitive lifting.

Overall, the crane is a reliable, flexible, and efficient solution for auto parts handling.

Technical Table for Quick Reference

| Parameter | Specification |

|---|---|

| Lifting Capacity | 3 Ton |

| Adjustable Span | 2.5 m |

| Adjustable Height | 1.85–3.7 m |

| Voltage & Frequency | 220V, 60Hz, 3-Phase |

| Travel Type | Manual / Optional Motorized |

| Safety Features | Overload protection, emergency stop |

| Mobility | Easy to assemble and relocate |

How to Get a Custom 3-Ton Gantry Crane

Getting a customized 3-ton adjustable gantry crane starts with defining your specific requirements and selecting a qualified supplier. Follow the steps below to ensure the crane meets your workshop and operational needs perfectly.

1. Define Your Requirements

Start by outlining the specifications your workshop needs. These details help the supplier design the crane correctly.

- Lifting Capacity: 3 tons

- Adjustable Height: e.g., 1.85–3.7 meters

- Adjustable Span: e.g., 2.5 meters

- Power Supply: 220V, 60Hz, 3-phase

- Mobility: Manual or motorized travel

- Safety Features: Overload protection, emergency stop, locking pins

- Construction Material: Steel or aluminum

2. Identify Potential Suppliers

Research reliable manufacturers or distributors that offer customization options for gantry cranes:

- Spanco: Adjustable height and span with tailored designs for material handling.

- Wallace Cranes: Fully custom gantry cranes designed for safe, efficient operations.

- Prowinch: Models from 1 to 5 tons with extensive customization options.

3. Request a Detailed Quote

After shortlisting suppliers, request detailed quotations that include all customization details. Provide the following information:

- Dimensions and workspace requirements

- Types and weights of parts to be handled

- Environmental conditions (indoor/outdoor, temperature, etc.)

- Mobility preferences (manual or motorized)

- Required safety standards or certifications

4. Evaluate Supplier Proposals

Compare the proposals carefully to ensure they align with your technical, operational, and financial expectations. Key factors include:

- Cost and budget fit

- Delivery lead time

- Warranty and post-purchase support

- Flexibility of customization options

5. Confirm and Place the Order

Once you've selected the best proposal, place your order and ensure all specifications are clearly documented. This step helps avoid misunderstandings and guarantees the crane is delivered and installed accurately and efficiently.

How to Select a Gantry Crane for Auto Parts Handling

Choosing the right gantry crane for auto parts handling requires balancing lifting capacity, flexibility, safety, and workflow efficiency. Follow these key selection steps to ensure optimal performance and reliability.

1. Determine the Required Lifting Capacity

Assess the heaviest auto parts you'll be handling. For instance, if you're lifting engines, gearboxes, or chassis components, ensure the crane's capacity exceeds the maximum weight of these parts. It's advisable to select a crane with a capacity slightly higher than your heaviest load to account for any unforeseen weight variations.

2. Consider Adjustable Height and Span

Auto parts vary in size and shape. An adjustable gantry crane allows you to modify the height and span to accommodate different parts. For example, a crane with a height range of 1.85–3.7 meters and an adjustable span of 2.5 meters can handle a wide variety of components efficiently.

3. Evaluate Mobility Needs

Depending on your workshop layout, you may require a crane that can move between workstations. Portable gantry cranes with locking caster wheels or motorized travel options offer flexibility in positioning, enhancing workflow efficiency.

4. Ensure Compliance with Safety Standards

Safety is paramount when handling heavy auto parts. Choose a crane that complies with relevant safety standards and certifications, such as CE or ISO. Features like overload protection, emergency stop buttons, and locking pins for height adjustments are essential for safe operations.

5. Assess Durability and Maintenance Requirements

Auto parts manufacturing environments can be demanding. Opt for cranes constructed from durable materials like steel or aluminum with anti-corrosion coatings to withstand harsh conditions. Additionally, consider the ease of maintenance and availability of spare parts to minimize downtime.

6. Consider Integration with Existing Workflow

Ensure the gantry crane integrates seamlessly into your existing workshop layout. The crane should complement your workflow, allowing for smooth transitions between different stages of the manufacturing process.

Related Resoucres: How to Adjusting Your Gantry Cranes

Height adjustable gantry crane with manual pined telescoping design

Height adjustable gantry crane with manual winch adjustable design

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch