5 Ton Euro Hoist & CD/MD Hoist | Hot Sale Electric Wire Hoists

Electric wire rope hoist for sale.5 ton Euro hoist china vs. CD/MD 5 ton rope hoist for your reference to get most cost-effective & suitable crane hoist.

Category: Wire Rope Hoist Crane

Your Trusted Wire Rope Hoist Crane Manufacturer & Supplier

Wire Rope Hoist 5 Ton for Sale, Hot Sale Electric Hoist Comparison

5 Ton Euro Hoist & 5 Ton CD/MD Hoist

Electric wire rope hoist for sale.5 ton Euro hoist china vs. CD/MD 5 ton rope hoist for your reference to get most cost-effective & suitable crane hoist.

A comprehensive guide on the comparison of Europeans tyle wire rope hoist & cd/md electric hoist for your reference. 5 ton Euro hoist china vs. 5 ton CD/MD electric rope hoist for your reference to get most cost-effective & suitable crane hoist.

History and current situation of electric wire rope hoist development in China

- Initial period - It is also the imitation period. In 1949, the Shanghai factory began to imitate DEMAG to manufacture the first wire rope hoist in China, and then produced it in small batches. However, in 1954, the factory switched to other products and no longer manufactured electric hoists. In 1953, Tianjin Factory began to imitate the Soviet Union's TV-type electric rope hoist, and in 1957 formed a series of products from 0.25 ton to 5 ton, becoming the first generation of electric wire rope electric hoist in China.

- Development period - In 1964, the 0.25 ton ~10 ton CD/MD wire rope electric hoist was self-reliantly developed . The biggest difference from the TV type wire rope hoist is that the motor and brake were integrated, and at that period, the MD type double speed electric hoist is produced. This is the second generation electric hoist in China

- In 1975, the hoisting industry carried out the first drawing rectification, and the CD/MD electric hoist was named CDI/MDI type.

- Improvement period - In 1983, the relatively advanced wire rope electric hoist from STAHL in Germany and the electric chain hoist from DEMAG were introduced, and trial production was started and put on the market. Some enterprises cooperate with foreign enterprises to upgrade the technology of CD/MD wire rope hoist, so that its performance has been significantly improved, and mass production has begun.

- In the late 1990s, some foreign companies began to build factories in China to produce electric hoists, such as KONE and DEMAG.

- Current situation - At present, my country's European-style electric wire rope hoists are promising, but due to the low brand recognition in international market, the Euro hoist from China are widely welcomed by third world countries and developing countries, and some European countries and areas due to the low-price competition. The European-style electric hoists at the high end of the market mainly include KONE and DEMAG products, which much more expensive.

Comparison of European style wire rope hoist & CD/MD electric hoist

European style wire rope hoists and CD/MD wire rope hoists are both types of electric wire rope hoists commonly used in industrial settings.

European style wire rope hoists are known for their compact design and high lifting capacity. They are often used in applications where there is limited headroom. They also tend to be more expensive than CD/MD wire rope hoists.

CD/MD wire rope hoists, on the other hand, are more versatile and can be used in a wider range of applications. They are typically less expensive than European style wire rope hoists and are known for their durability and reliability.

Overall, the main differences between the two types of wire rope hoists are their design, lifting capacity, and price.

Main difference of Euro hoist and CD/MD wire rope hoist in China

European style electric wire rope hoist up to 80 ton

- 1. Low headroom, reduce the building height of the workshop, and the limit size is small, increasing the usable area of the workshop;

- 2.High precision gear, grinding processing, low working noise;

- 3. The reducer is small in size, maintenance-free design, well sealed without oil leakage, and low maintenance cost;

- 4. The motor has high efficiency, high energy output (speed can reach 3000r/min), and low energy consumption;

- 5. The hook forgings are quenched and tempered 34CrMov, anti-friction bearings lubricated throughout their life;

- 6. Electrical components Schneider;

- 7. Protection level: motor IP54/IP55,

- 8. Speed frequency conversion, wide range of options, wider application;

- 9. High-strength galvanized steel wire rope, no need to apply anti-rust oil, maintenance-free, clean, good flexibility, breaking force 2160kN/mm2, more wear-resistant;

- 10. Electric continuity rate 60%ED;

CD/MD style electric wire rope hoists up to 50 ton

- 1. Designed in the 1970s, the cd/md wire rope hoist was low in lifting height, and large in limit size for hoisting;

- 2. Gear , hobbing processing, large working noice.

- 3. The reducer is large in size, poorly sealed and prone to oil leakage, which requires regular lubrication and higher maintenance costs;

- 4. The efficiency of the motor is low (speed 1380r/min), and the energy consumption is large;

- 5. The hook is an ordinary forged piece;

- 6. Chint electrical components;

- 7. Protection level: all are IP44;

- 8. Speed single speed or double speed, the value is fixed, the selection range is limited.

- 9. Ordinary steel wire rope needs to be coated with anti-rust oil regularly, and the breaking force is 1360kN/mm2;

- 10. Electric continuity rate 25%ED;

Main types

There are several variants or types of both European style wire rope hoists and CD/MD wire rope hoists, each with their own specific features and capabilities. Here are some examples:

European style wire rope hoists:

- Single girder hoists: These hoists are designed to run on a single girder beam and are ideal for applications where space is limited.

- Double girder hoists: These hoists are designed to run on two girder beams and can handle heavier loads than single girder hoists.

- Low headroom hoists: These hoists are designed for applications where headroom is limited, such as in automotive and steel manufacturing.

- Explosion-proof hoists: These hoists are designed for use in hazardous environments, such as in the oil and gas industry.

CD/MD wire rope hoists:

- Low headroom hoists: These hoists are designed for applications where headroom is limited, but can handle heavier loads than European style low headroom hoists.

- Ultra-low headroom hoists: These hoists are designed for applications where headroom is extremely limited, such as in underground mining.

- High-speed hoists: These hoists are designed for applications where speed is important, such as in warehousing and logistics.

- Explosion-proof hoists: These hoists are designed for use in hazardous environments, such as in chemical and petrochemical plants.

It's important to note that these are just some examples of the variants or types of each type of hoist, and there may be others available depending on the manufacturer and model. It's always best to consult the manufacturer's specifications for the specific hoist you are interested in.

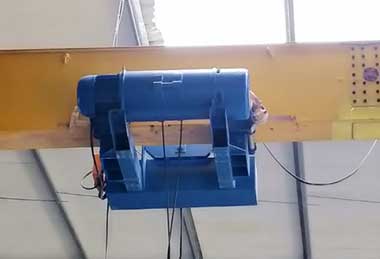

General type euro hoist China design

General design cd/md electric wire rope hoist

Low headroom euro hoist

cd/md wire rope hoist with low headroom design

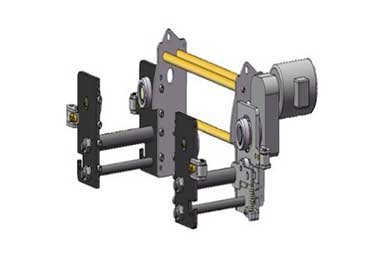

Euro hoist for double girder crane design

CD/MD type double girder hoist

Fixed type euro hoist , mounted on trolley frame

Fixed type cd/md wire rope hoist, mounted on hoist trolley frame

Constructions & parts

The construction and parts of European style wire rope hoists and CD/MD wire rope hoists are different from each other.

European style wire rope hoists are typically designed with a compact and lightweight construction, which makes them suitable for use in applications where space is limited. They are usually made with high-quality materials such as aluminum and stainless steel to ensure durability and longevity. The main parts of a European style wire rope hoist include the motor, gearbox, drum, wire rope, hook, and brake system.

CD/MD wire rope hoists, on the other hand, are designed with a more robust construction to handle heavier loads and more demanding applications. They are typically made with cast iron or steel components to provide strength and durability. The main parts of a CD/MD wire rope hoist include the motor, gearbox, drum, wire rope, hook, and brake system, as well as additional safety features such as limit switches and overload protection.

In summary, European style wire rope hoists are designed with a compact and lightweight construction while CD/MD wire rope hoists are designed with a more robust construction to handle heavier loads.

- Euro wire rope electric hoist design - Low headroom, reduce the building height of the workshop, small limit size, increase the usable area of the workshop;

- Height limiter of Euro hoist china - The screw-type height limiter has higher precision and a wide adjustment range, which can effectively realize the fast and slow switching and stop function when rising and falling, and there is no risk of collision to the hoist.

- Wiring - of european style electric rope hoist - Aviation plug, easy to install.

- Wire rope guide of euro hoist - Industrial plastic rope guide, light weight, good wear resistance, effectively reducing the wear of the wire rope

- CD/MD wire rope electric hoist design - Designed in the 1970s, large in size, with lower lifting height

- Height limiter of cd/md electric wire rope hoist - The old-fashioned limit device, and the limit accuracy can be affected by operation, installation and maintenance.

- The wiring of cd/md wire rope hoist is relatively complicate by connecting each wire one by one.

- Rope guide of Cd/md wire rope hoist - Ordinary cast iron rope guide

Advantages and disadvantages

European style wire rope hoists and CD/MD wire rope hoists both have advantages and disadvantages.

Advantages of European style wire rope hoists include:

- Compact design that requires less headroom

- High lifting capacity

- Smooth and precise operation

- Low maintenance requirements

- Suitable for use in a wide range of applications

Disadvantages of European style wire rope hoists include:

- More expensive than CD/MD wire rope hoists

- Limited availability of spare parts and accessories

- Not suitable for extremely heavy loads or harsh environments

Advantages of CD/MD wire rope hoists include:

- Versatile and can be used in a wide range of applications

- Durable and reliable construction

- Lower cost compared to European style wire rope hoists

- Available spare parts and accessories

- Suitable for heavy loads and harsh environments

Disadvantages of CD/MD wire rope hoists include:

- Require more headroom compared to European style wire rope hoists

- Less compact design compared to European style wire rope hoists

- Can be louder and less precise in operation compared to European style wire rope hoists

In summary, the advantages and disadvantages of each type of electric wire rope hoist depend on the specific application and requirements. European style wire rope hoists are ideal for applications with limited headroom and high lifting capacity, while CD/MD wire rope hoists are suitable for a wider range of applications and offer a lower cost option

Applications

LD type cd/md wire rope hoist crane

LH double girder cd/md rope hoist crane

MHO single girder euro hoist gantry crane

MH single gider hoist gantry crane

MGO double girder europ hoist crane

MG double girder cd/md rope hoist gantry crane

European style wire rope hoists and CD/MD wire rope hoists are both used in a wide range of industrial applications. Here are some typical applications for each type:

European style wire rope hoists:

- Automotive industry: for lifting engines, transmissions, and other heavy components

- Steel industry: for lifting steel plates, beams, and other heavy materials

- Construction industry: for lifting building materials and equipment to higher levels

- Manufacturing industry: for lifting heavy machinery and equipment during production

- Mining industry: for lifting heavy loads in underground mines

CD/MD wire rope hoists:

- Warehousing: for lifting and moving heavy pallets and containers

- Manufacturing: for lifting and moving heavy machinery and equipment during production

- Construction: for lifting building materials and equipment to higher levels

- Mining: for lifting heavy loads in open-pit mines

- Transportation: for loading and unloading cargo from trucks, ships, and trains

It's important to note that these are just some typical applications and both types of hoists can be used in a wide range of industries and applications depending on the specific requirements.

Hot sale markets

European style wire rope hoists are popular in many countries around the world, including:

- Germany: German manufacturers are known for producing high-quality European style wire rope hoists, and they are widely used in various industries in Germany.

- France: European style wire rope hoists are commonly used in the automotive and steel manufacturing industries in France.

- Italy: Italian manufacturers produce a range of European style wire rope hoists for various applications, including construction and mining.

- United Kingdom: European style wire rope hoists are used in various industries in the UK, including manufacturing, construction, and logistics.

CD/MD wire rope hoists are also popular in many countries around the world, including:

- China: Chinese manufacturers produce a wide range of CD/MD wire rope hoists for various applications, and they are widely used in manufacturing and construction industries in China.

- Japan: CD/MD wire rope hoists are commonly used in manufacturing and logistics industries in Japan.

- United States: CD/MD wire rope hoists are widely used in various industries in the US, including manufacturing, construction, and mining.

- Australia: CD/MD wire rope hoists are used in various industries in Australia, including mining and construction.

It's important to note that both European style wire rope hoists and CD/MD wire rope hoists are widely used in many countries around the world, and their popularity may vary depending on the specific industry and application.

Operation:

- European style wire rope hoists are designed for smooth and precise operation, with a focus on control and accuracy. They are often used in applications where precision is important, such as in manufacturing and automotive industries.

- CD/MD wire rope hoists are designed for heavy-duty operation, with a focus on durability and reliability. They are often used in applications where heavy loads need to be lifted and moved quickly, such as in construction and mining industries.

Installation:

- European style wire rope hoists are typically designed for easy installation and can be mounted in a variety of positions. They are often used in applications where space is limited, so they are designed to be compact and easy to install.

- CD/MD wire rope hoists are typically larger and heavier than European style wire rope hoists, so they require more space and may be more difficult to install. They are often used in applications where heavy loads need to be lifted and moved over long distances.

Maintenance:

- European style wire rope hoists require regular maintenance to ensure smooth operation and prevent wear and tear. They typically have fewer moving parts than CD/MD wire rope hoists, which makes them easier to maintain.

- CD/MD wire rope hoists require regular maintenance to ensure they remain durable and reliable. They have more moving parts than European style wire rope hoists, which means they require more maintenance. However, they are often designed with features that make maintenance easier, such as removable covers and easy access to components.

In summary, European style wire rope hoists are designed for smooth and precise operation, easy installation, and low maintenance requirements. CD/MD wire rope hoists are designed for heavy-duty operation, larger installation requirements, and more maintenance requirements.

Price

The price difference between European style wire rope hoists and CD/MD wire rope hoists can vary depending on several factors, such as the manufacturer, model, capacity, and features. Generally, European style wire rope hoists are more expensive than CD/MD wire rope hoists due to their compact design and higher lifting capacity.

The price range for European style wire rope hoists can range from a few thousand dollars for a small capacity hoist to tens of thousands of dollars for a high-capacity hoist with advanced features. A typical European style wire rope hoist with a lifting capacity of 5-10 tons can cost anywhere from 5,000 to 15,000

The price range for CD/MD wire rope hoists is generally lower than that of European style wire rope hoists. A typical CD/MD wire rope hoist with a lifting capacity of 5-10 tons can cost anywhere from 3,000 to 10,000 depending on the manufacturer and features.

It's important to note that the initial purchase price is not the only factor to consider when choosing between European style wire rope hoists and CD/MD wire rope hoists. Other factors such as maintenance costs, durability, reliability, and suitability for the specific application should also be taken into consideration.

Why European style electric wire rope hoist is more popular

It seems they are used in the same application conditions. But why the European style electric wire rope hoists are much more pupluar ? What are their typical users ?

European style wire rope hoists are more popular in some industrial applications due to their compact design and high lifting capacity. They are often used in applications where there is limited headroom, such as in automotive and steel manufacturing.

The typical users of European style wire rope hoists are those who require a high level of precision and control in their lifting operations, as well as those who need to lift heavy loads in a limited space. Some typical users of European style wire rope hoists include manufacturers, warehouses, construction companies, and mining companies.

CD/MD wire rope hoists are also widely used in industrial applications, but they are typically designed for heavier loads and more demanding environments. They are often used in applications where there is more space available for the hoist to operate.

The typical users of CD/MD wire rope hoists are those who require a durable and reliable hoist for heavy lifting operations. Some typical users of CD/MD wire rope hoists include manufacturing plants, construction sites, and mining operations.

Overall, the choice between European style wire rope hoists and CD/MD wire rope hoists depends on the specific application and requirements. European style wire rope hoists are more popular in some applications due to their compact design and high lifting capacity, while CD/MD wire rope hoists are designed for heavier loads and more demanding environments.

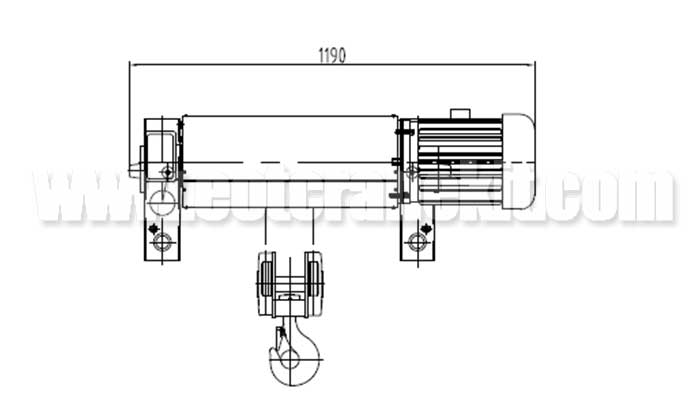

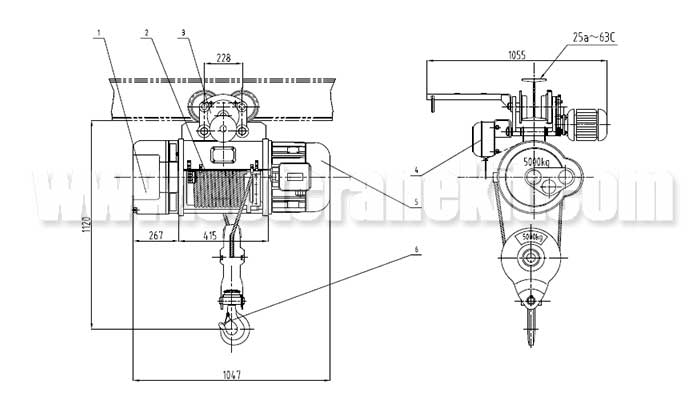

Dimensions and weight

The dimensions and weight difference between European style wire rope hoists and CD/MD wire rope hoists with the same lifting capacity and lifting height can vary depending on the manufacturer and specific model. However, there are some general differences to consider:

European style wire rope hoists are typically more compact and lighter in weight than CD/MD wire rope hoists with the same lifting capacity and lifting height. This is due to their design, which focuses on a compact and lightweight construction to allow for use in limited space applications.

CD/MD wire rope hoists are typically larger and heavier than European style wire rope hoists with the same lifting capacity and lifting height. This is due to their design, which focuses on durability and reliability for heavy-duty lifting applications.

The specific dimensions and weight of each type of hoist will depend on the manufacturer and model. It's important to consult the manufacturer's specifications to determine the exact dimensions and weight of a specific hoist.

It's also important to note that the dimensions and weight of the hoist are just one factor to consider when selecting the appropriate hoist for a specific application. Other factors such as lifting speed, control options, and maintenance requirements should also be taken into consideration.

5 Ton electric wire rope hoist comparison : European style vs. Cd/MD Types

5 ton european style electic wire rope hoist

Item | Electric wire rope hoist European style | ||

Rated lifting capacity | t | 5 | |

Lifting height | m | 7 | |

Speed | Hoist traveling speed | m/min | 2.0~20 (inverter control) |

Lifting speed | 0.8/5.0 (dual speed) | ||

Working class | / | FEM2M (ISO M5) | |

Power supply | V/Hz/Ph | 380V 50Hz 3Ph | |

Control voltage | V | 36 | |

Hoist traveling power | KW | 0.64 | |

Hoisting power | 1.0/6.1 | ||

Recommended track width | mm | 120-450 | |

Total design weight | kg | 430 | |

Protection class | / | IP54 | |

Insulation grade | / | F | |

Ambient temperature | / | -20℃-+40℃ | |

Control method | / | Pendant control | |

Lifting motor & Travelling motor

Squirrel Cage and three-in-one hoist motor.

Light alloy shell, low carbon alloy forged steel.

High quality seals, heavy duty industrial gear oil.

Electromagnetic disc type brake system

Protection class IP54, Insulation grade F

Main frame with trolley

Main structure material high strength Q235B, with travelling system. Rational and compact design,Increase the hoist lifting height; make full use of the vertical space.

Rope guide

High strength nylon rope guide, installed on the winding drum to guide the wire rope to prevent constant winding of steel wire and prolong the life of the drum

Overload limiter

Under overload condition, cut off the power of the crane

5 ton cd/md electic wire rope hoist

Item |

| Electric wire rope hoist | |

Rated lifting capacity | t | 5 | |

Testing capacity | 6.25 | ||

Lifting height | m | 21.41 | |

Speed | Cross traveling speed | m/min | 20 |

Lifting speed | 8 | ||

Working class | / | A3 | |

Power supply | V/Hz/Ph | 380V 50Hz 3Ph | |

Control voltage | V | 36 | |

Hoist traveling power | KW | 0.8 | |

Hoisting power | 7.5 | ||

Total power | 8.3 | ||

Recommended Track width | mm | 116-160 | |

Wire rope diameter | mm | 15 | |

Net Weight | kg | 686 | |

Protection class | / | IP54 | |

Insulation grade | / | F | |

Ambient temperature | / | -20℃-+40℃ | |

Control method | / | Pendant control | |

Country of origin | / | China | |

Motor

Special designed Squirrel-cage motor for the electric hoist.

Maintenance free.

Insulation grade F.

Protection class IP54.

Electromagnetic brake system

Hoist lifting reducer

Totally enclosed type with Splash Lubrication, gear box shell pressure casting

Electric trolley

Alloy gear and wheels, 125% testing load of the rated capacity. Braking method please see the travelling motor details.

Rope guide

Installed on the winding drum to guide the wire rope, nodular cast iron

Overload limit

For lifting protection, monitor the hoist situation

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch