Single pole busbar, your overhead crane electric busbar system

Single pole busbar for overhead travelling cranes, your overhead crane electric busbar system, safe, reliable & insulated single pole crane busbar system.

| Crane part | Single pole busbar, crane busbar system |

| Minimum of order | 1000 m |

Category: Crane Kit Parts

Single pole bus bar, also named single pole sliding wire or single pole conductor bar is a modern and advanced crane power supply system for overhead travelling cranes, fabricated in compliance with the latest regulations to ensure crane power supply safety, efficient and stable. The single pole busbars feed the power to your overhead travelling cranes through four lines which are available with copper crane conductor bar and aluminum crane conductor bar.

Single pole busbar can be adopted in indoor or outdoor applications and can be installed vertically or horizontally, on straight or curved system. For outdoor applications or harsh conditions, the single pole busbars are available with a protective cover of different sizes to protect crane conductor bars of various sizes to ensure overhead travelling crane safety which is antioxidant, UV resistant, impact resistant and is applicable to environments with the temperature of -40 ~ 115℃.

Features ofsingle polecrane conductor busbar

- Single pole crane conductor barscanbefreelyassembledorcombined to fit your powerfeeding and distribution systems.

- Coppercrane conductor bar and aluminumcrane conductor bar are optional for your applications.

- Copper crane busbar of 200A-5000A and aluminum crane busbar of 150A-3000A are available.

- Adoptingthecoldweldingtechnology, the single pole aluminum conductor barsare integrated withstainlesssteelstrip to prevent electric corrosion.

- The"V"or"U"groovecontactfaceensuresthecurrentcollectorrunsmoothly.

- Fast,largeloadingcapacity,high heatresistant and with protection levelofIP23.

Single pole busbar, crane busbar system

Single pole busbar, crane busbar system

Single pole busbar, crane busbar system

Advantages ofsingle pole electric busbar system

- Insulated single pole busbar with PVChousing protection.

- Safejointing kitsbetweentheconductors,withPVCorAluminumhousing.

- Insulated,safe,lowresistance,every-saving,small,light,simpletoinstall,etc.

- Dust-proof,rain-proof,dew-proof,snow-proof,high safety to ensure outdoor application

- Wide application for Overhead Travelling Cranes, EotCranes,Electric Hoist, JibCranes, etc. ,

Application of overhead crane electric busbar system

The, single pole busbars have a widely applications which are frequently used on overhead travelling cranes, eot crane, electric hoists, jib crans and other lifting equipment. As for overhead travelling cranes, the single pole bus bars are widely used on double girder overhead crane systems for there is no limitations on the travelling length of overhead travelling cranes which usually require four current conductors .

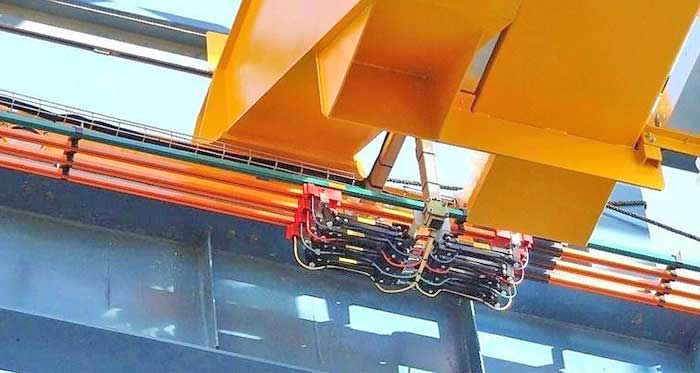

Single pole busbar for overhead travelling crane system

Single pole busbar system for overhead crane

Overhead crane electric busbar system

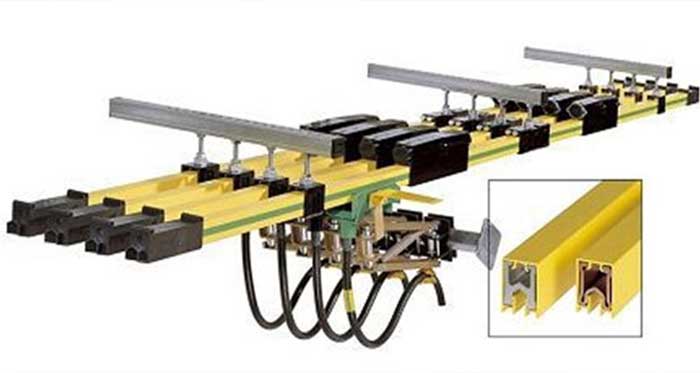

Main Components of overhead crane electric busbar system

Single pole crane conductor barscanbefreelyassembledorcombined to fit your powerfeeding and distribution systems.Copper crane busbar of 200A-5000A and aluminum crane busbar of 150A-3000A are available are available for meet the requirements of your applications. And also, full set of overhead crane electric busbar systems are available which are consisted of conductor bar, protective housing cover, jointing kits, feed sets, end caps, hangers, expansion section, current collector, tow arm, support bracket, isolation section, etc.

Overhead crane electric busbar system

- Housing: 4m or 6m standard section and customized are available.

- Snap-in joint :to ensure mechanical and electrical continuity, provided with insulated protection cover

- Feed set: available with End feeds or line feeds

- End caps to close the open ends of the conductor bars.

- Hangers:-to attach crane busbar to crane girders which are available with sliding and fix point hangers, with standard distance between suspension appoints of 1500mm to 2000mm, for indoor and outdoor applications.

- Expansion: to compensate the different expansions between copper conductors and steel-or concrete structures, in varying temperatures to ensure electrical power supply without interruption.

- Expansion joints are installed based on actual installation when the length between feeds, curves, switches or other fix points is exceeding 20m.

- Isolating section -Isolating sections are required if parts of the system or individual rails are to be de-energized within a conductor rail system.

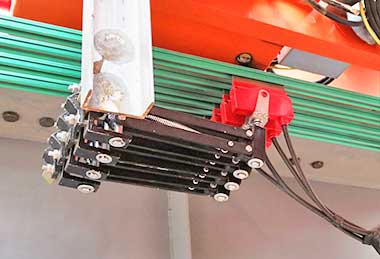

- Collectors - made of carbon brush, reinforced nylon and galvanized or spray-paint metal .

Single pole busbar, crane busbar system

Single pole busbar, crane busbar system

Single pole busbar, crane busbar system

Select the right crane power line to your overhead travelling cranes

For power line supply, we can provided you the Seamless crane busbar, Multipolar crane busbar and Single pole busbar, and complete overhead crane electrical busbar system, etc. Usually, seamless crane busbar is adopted in single girder overhead travelling crane system, single pole crane busbar is used in double girder overhead overhead travelling crane system. According to your particular application and your requirements, we can select the most suitable power supply lines for your overhead travelling cranes.

If you need the single pole crane busbar for your overhead crane system, please feel free to contact us to confirm the details of the single pole busbar.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch