5 Ton Storage Bridge Crane for Steel Coil Handling in Steel Plant

5 ton storage bridge crane and overhead crane for 5 ton steel coils and rolled steels handling and transporting in a steel production plant.Click it now!

Category: Bolivia

Your Trusted Storage Bridge Crane Manufacturer & Supplier

5 Ton Storage Bridge Crane for Steel Coil Handling

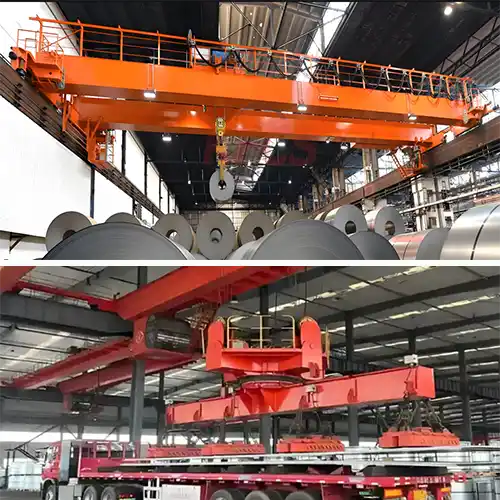

5 ton Stroage Bridge Crane and Overhead Crane for 5 Ton Steel Coils and Rolled Steels Handling and Transporting

5 ton stroage bridge crane and overhead crane for 5 ton steel coils and rolled steels handling and transporting in a steel production plant.

5 Ton Storage Bridge Crane for Steel Coil Handling:

In the intricate realm of steel production, where precision and efficiency intertwine, the role of material handling cannot be overstated. At the heart of this industrial dance is the 5 Ton Storage Bridge Crane, a robust apparatus designed for the nuanced task of handling steel coils within a production plant. As we delve into the importance of efficient material handling in steel production, the spotlight falls on the indispensable role played by this stalwart crane.

The 5 Ton Storage Bridge Crane is a specialized machinery crafted for lifting and transporting substantial steel coils seamlessly. Its load-bearing capacity is a testament to its prowess in navigating the demands of a steel production environment.

Importance of Efficient Material Handling in Steel Production

Efficient material handling stands as the cornerstone of a well-oiled steel production process. As raw materials traverse various stages of manufacturing, the need for a streamlined, reliable, and swift handling system becomes paramount. The 5 Ton Storage Bridge Crane emerges as a hero in this narrative, offering a solution that goes beyond mere transportation.

In the dynamic landscape of steel production, time is of the essence. Swift and precise handling of steel coils ensures a continuous flow in the production of rolled steel. This not only optimizes operational efficiency but also contributes significantly to meeting production deadlines and maintaining a competitive edge in the market.

The significance of efficient material handling is not confined to speed alone. Safety, an ever-present concern in industrial settings, is also addressed by the 5 Ton Storage Bridge Crane. By providing a reliable and controlled means of moving heavy steel coils, the crane minimizes the risk of workplace accidents, enhancing the overall safety standards within the production plant.

As we unravel the layers of this industrial marvel, the subsequent sections will delve deeper into the application, project s, benefits, technical specifications, and the promising future of the 5 Ton Storage Bridge Crane. Join us on this journey through the intricacies of steel production efficiency, where every coil lifted by the crane propels the industry forward.

5 Ton Storage Bridge Crane for Steel Coil Handling

The 5 Ton Storage Bridge Crane is a types of steel coil handling cranes which is a mechanical powerhouse meticulously designed for the specific task of handling and transporting steel coils within the confines of a steel production plant. It stands as a testament to precision engineering, combining strength, agility, and control to seamlessly navigate the challenges inherent in the industrial landscape.

This crane operates on the principle of a bridge-like structure that spans the workspace, providing a stable and secure platform for lifting and moving heavy loads. The term "storage" in its nomenclature alludes to its capacity not just for transport but also for strategic placement, contributing to an organized and efficient material flow.

The steel coil storage overhead crane is equipped with a robust hoisting system that ensures the precise lifting and lowering of steel coils, allowing for intricate maneuvers essential in the production process. Its design is a marriage of strength and finesse, making it a versatile asset in the hands of steel manufacturers.

Significance of the Crane's Load Capacity

At the core of the 5 Ton Storage Bridge Crane's functionality is its impressive load capacity. The ability to handle 5-ton steel coils speaks volumes about its strength and reliability. This load-bearing prowess is a critical factor in its effectiveness within a steel production plant.

In an environment where large-scale operations are the norm, the crane's capacity becomes a determining factor in the scale of production it can facilitate. The 5-ton limit ensures that it can handle substantial loads, contributing to a continuous and uninterrupted production flow. This not only enhances efficiency but also positions the crane as a key player in meeting the demands of a high-volume steel production setting.

As we navigate further into the realms of application and project s, the real-world impact of this load capacity will become even more apparent. Join us on this journey as we uncover the practical applications and success stories of the 5 Ton Storage Bridge Crane in the dynamic world of steel coil handling.

Application of 5 Ton Storage Bridge Cranes

Handling and Transporting Steel Coils

The primary application of the 5 Ton Storage Bridge Crane lies in its adept handling and transportation of steel coils. As foundational components in steel production, coils are unwieldy and heavy, requiring specialized equipment for efficient movement. This is where the crane steps in with its precision and strength.

The crane's hoisting system allows it to delicately lift steel coils, ensuring a secure grip and controlled movement. Its bridge-like structure facilitates the transportation of these coils across the production plant, seamlessly navigating the often intricate layout of machinery and workstations. This capability is crucial in maintaining a steady and organized flow of materials, a prerequisite for a streamlined production process.

Importance in a Steel Production Plant

Within the dynamic landscape of a steel production plant, the 5 Ton Storage Bridge Crane plays a pivotal role. Its importance can be understood through various lenses:

- Operational Efficiency: The crane contributes to operational efficiency by reducing downtime in material handling. Swift and precise movement of steel coils ensures that the production line operates at an optimal pace, minimizing delays and maximizing output.

- Continuous Flow: Steel production is a continuous process, and any interruption in material handling can disrupt the entire workflow. The crane's ability to handle 5-ton steel coils ensures a continuous and seamless flow, preventing bottlenecks and optimizing overall production.

- Strategic Placement: The crane's capacity for strategic placement of steel coils is instrumental in organizing the workspace. By precisely positioning materials where they are needed, it enhances accessibility and minimizes the need for additional manual handling.

- Safety: In an industrial setting, safety is paramount. The crane's role in handling heavy loads mitigates the risk of accidents associated with manual handling. This not only safeguards the workforce but also contributes to a safer working environment.

As we explore further into real-world project s and delve into the benefits of employing this crane, the multifaceted importance of the 5 Ton Storage Bridge Crane in a steel production plant will become even more apparent. Join us on the next leg of our journey to uncover the practical implications and success stories tied to this indispensable industrial asset.

Overview of a Specific Project of Storage Bridge Crane

To illustrate the real-world impact of the 5 Ton Storage Bridge Crane, let's delve into a specific project where this robust machinery played a central role. In a bustling steel production plant, a project was initiated to optimize material handling processes and enhance overall efficiency.

The challenge at hand was the handling of 5-ton steel coils, a task that demanded precision, speed, and reliability. The solution came in the form of the 5 Ton Storage Bridge Crane, strategically deployed to streamline the movement of these hefty coils within the production facility.

Details on the Handling of 5-Ton Steel Coils

The crane's hoisting system, fortified by its 5-ton load capacity, proved instrumental in the successful execution of the project. The detailed handling process involved:

- Lifting: The crane delicately lifted 5-ton steel coils with its precision-engineered hoisting mechanism. This ensured a secure grip on the coils, minimizing the risk of damage during transit.

- Transportation: Once hoisted, the crane smoothly transported the steel coils across the production plant. Its bridge structure allowed it to navigate through tight spaces and intricate layouts, reaching designated workstations with ease.

- Placement: The strategic placement of steel coils at specific points within the production line was a key focus. The crane's ability to position the coils precisely contributed to a more organized and efficient workspace.

Contribution to Seamless Flow in Rolled Steel Production

The impact of the 5 Ton Storage Bridge Crane on the seamless flow of rolled steel production was remarkable. By expediting the handling and transportation of 5-ton steel coils, the crane played a pivotal role in:

- Minimizing Downtime: The swift and controlled movement of materials reduced downtime associated with manual handling or less efficient equipment. This optimization translated to a continuous production flow.

- Optimizing Production Rates: The crane's ability to handle substantial loads meant that the production plant could operate at optimal capacity. This, in turn, contributed to higher production rates and met the demands of a competitive market.

- Reducing Errors: The precision of the crane's movements reduced the likelihood of errors in material placement. This not only improved the overall quality of the rolled steel but also minimized the need for corrective measures.

In this project , the 5 Ton Storage Bridge Crane emerged as a catalyst for efficiency, demonstrating its capacity to enhance material handling and contribute to the seamless flow of rolled steel production. As we continue our exploration, we will uncover the broader benefits of using this crane, touching on increased efficiency, enhanced safety, cost-effectiveness, and the technical specifications that make it a standout asset in the realm of steel production. Join us on this journey of industrial innovation and optimization.

Benefits of Using a 5 Ton Storage Bridge Crane

Increased Efficiency

Streamlining Material Handling Processes

Efficiency is the lifeblood of any industrial operation, and the 5 Ton Storage Bridge Crane stands as a beacon of efficiency in the realm of steel production. One of its primary benefits lies in the seamless streamlining of material handling processes.

- Swift Operations: The crane's precision-engineered hoisting system and bridge-like structure facilitate the swift and controlled handling of 5-ton steel coils. This expedites the movement of materials across the production plant, reducing the time required for manual transportation.

- Optimized Workflows: By providing a reliable and efficient means of lifting and transporting materials, the crane optimizes workflows. This optimization ensures that each step of the production process seamlessly transitions into the next, creating a harmonious and well-coordinated operation.

Minimizing Downtime

Downtime in industrial settings can be a significant impediment to productivity. The 5 Ton Storage Bridge Crane acts as a catalyst in minimizing downtime through various mechanisms.

- Continuous Material Flow: The crane's ability to handle 5-ton steel coils ensures a continuous material flow. This is crucial in preventing bottlenecks and interruptions in production, as materials move seamlessly from one stage to another.

- Reduced Manual Handling: Manual handling of heavy materials is not only time-consuming but also prone to errors and accidents. By automating the lifting and transportation of steel coils, the crane eliminates the need for extensive manual labor, reducing the risk of injuries and ensuring consistent production.

- Efficient Changeovers: In scenarios where different coil sizes or materials are required for production, the crane's adaptability and speed in handling changes contribute to quick changeovers. This agility further minimizes the downtime associated with transitions between different production requirements.

As we explore further into the benefits of the 5 Ton Storage Bridge Crane, the focus will shift to its role in enhancing safety within the industrial environment. Join us as we unravel how this crane becomes not just an efficiency enhancer but also a guardian of workplace well-being.

Enhanced Safety

Features Ensuring Safe Coil Handling

In the high-stakes environment of a steel production plant, safety takes precedence. The 5 Ton Storage Bridge Crane is not merely a workhorse for material handling; it is also equipped with features meticulously designed to ensure safe coil handling.

- Precision Controls: The crane's control mechanisms are engineered for precision. This allows operators to have fine-tuned control over the lifting, lowering, and movement of steel coils. The ability to maneuver with accuracy ensures that materials are handled with utmost care.

- Overload Protection: To mitigate the risk of overburdening the crane, modern models are often equipped with overload protection features. These mechanisms automatically detect when the load exceeds the designated capacity, triggering safeguards to prevent accidents and equipment damage.

- Emergency Stop Systems: In unforeseen circumstances or emergencies, the crane is equipped with emergency stop systems. This allows for immediate halting of operations, preventing potential accidents or damage to materials and equipment.

Reduction of Potential Workplace Accidents

The deployment of the 5 Ton Storage Bridge Crane contributes significantly to the reduction of potential workplace accidents within a steel production plant.

- Minimized Manual Handling: The crane's primary role is to automate the lifting and transportation of heavy steel coils. By minimizing manual handling, it reduces the risk of musculoskeletal injuries and accidents associated with the physical strain of moving substantial loads.

- Controlled Movements: The crane's controlled and automated movements reduce the likelihood of collisions or accidents during material handling. Operators can navigate the crane with precision, avoiding obstacles and ensuring a safe passage for materials.

- Training and Compliance: Operators undergo specialized training to operate the crane safely. Additionally, the design and features of the crane often align with industry safety standards and regulations. This commitment to compliance further enhances the overall safety culture within the production environment.

The 5 Ton Storage Bridge Crane, beyond its efficiency-driven benefits, emerges as a guardian of workplace safety. Its features and mechanisms are a testament to the commitment to creating a secure environment for both the workforce and the materials being handled. As we delve deeper into the economic advantages and technical specifications of the crane, the holistic picture of its significance in steel production will come into sharper focus. Join us as we uncover the layers of this industrial marvel.

Cost-Effectiveness

Resource Optimization in Steel Production

The utilization of the 5 Ton Storage Bridge Crane extends beyond its immediate operational benefits—it becomes a cornerstone in the broader strategy of resource optimization within the realm of steel production.

- Labor Efficiency: By automating the lifting and transportation of steel coils, the crane reduces the reliance on manual labor for these physically demanding tasks. This not only minimizes labor costs but also ensures that human resources are utilized for more intricate and value-added aspects of the production process.

- Energy Efficiency: The precision controls of the crane contribute to energy efficiency. Its ability to move materials swiftly and with minimal waste translates to reduced energy consumption, aligning with sustainability goals and cutting operational costs associated with energy use.

- Material Utilization: The crane's controlled movements and strategic placement of materials contribute to optimized material utilization. This not only minimizes material waste but also ensures that resources are used efficiently, reducing the overall costs associated with raw materials.

Long-Term Economic Advantages

Investing in a 5 Ton Storage Bridge Crane offers compelling long-term economic advantages for steel production plants.

- Equipment Longevity: These cranes are built with durability in mind. The robust construction and quality materials ensure a long lifespan, minimizing the need for frequent repairs or replacements. This longevity translates to sustained operational efficiency and cost savings over time.

- Increased Production Capacity: The crane's ability to handle 5-ton steel coils enhances the overall production capacity of a plant. This increased capacity positions the facility to meet growing demands, capitalize on market opportunities, and achieve economies of scale, ultimately leading to long-term economic benefits.

- Adaptability to Changing Needs: The crane's adaptability to different coil sizes and materials ensures that it remains a relevant and valuable asset even as production requirements evolve. This adaptability safeguards the initial investment, allowing the crane to seamlessly integrate into changing operational landscapes.

In the complex dance of resource management and economic sustainability, the 5 Ton Storage Bridge Crane emerges as a strategic investment. Its role in optimizing labor, energy, and material resources contributes not only to immediate operational efficiency but also to the long-term economic viability of a steel production plant. As we transition to the exploration of the crane's technical specifications, we delve into the engineering marvel that underpins its functionality. Join us on this journey through the intricate details that make the 5 Ton Storage Bridge Crane an indispensable asset in the world of steel production.

Technical Specifications of Steel Coil Storage Bridge Crane

Structural Components

Description of Key Structural Elements

The 5 Ton Storage Bridge Crane's efficiency and reliability are rooted in its meticulously engineered structural components, each serving a specific purpose to ensure optimal functionality.

- Bridge Girder: The bridge girder forms the horizontal beam that spans the workspace, providing the crane with its characteristic bridge-like structure. This component supports the trolley and hoist, allowing for the horizontal movement of the crane along the length of the facility.

- Trolley: Mounted on the bridge girder, the trolley is responsible for the lateral movement of the crane. It facilitates the precise positioning of the hoist and load, allowing for flexible and strategic material handling within the production plant.

- Hoist: The hoist is the lifting mechanism responsible for elevating and lowering heavy loads, such as the 5-ton steel coils. Equipped with precision controls, the hoist ensures a secure grip on materials and enables controlled movements during the handling process.

- End Trucks: Positioned at either end of the bridge girder, the end trucks house the wheels and motors necessary for the horizontal movement of the crane. These trucks play a crucial role in the overall stability and mobility of the crane.

Materials Used in Construction

The durability and reliability of the 5 Ton Storage Bridge Crane are intrinsically tied to the quality of materials used in its construction.

- Steel Alloys: The structural components, including the bridge girder, trolley, and end trucks, are often constructed using high-strength steel alloys. These alloys provide the necessary combination of strength and resilience required to support heavy loads and withstand the rigors of industrial usage.

- Electrical Components: The electrical components, including motors, controls, and wiring, are designed with materials that prioritize longevity and performance. Corrosion-resistant coatings and robust insulation ensure the continued functionality of these elements in challenging environments.

- Load-Bearing Elements: Components directly involved in load-bearing, such as hooks and cables in the hoist mechanism, are typically constructed from high-tensile materials. These elements undergo rigorous testing to ensure they meet safety standards and can withstand the stresses of lifting heavy loads.

The careful selection of materials and the robust construction of key structural elements contribute to the crane's ability to handle 5-ton steel coils efficiently. As we conclude our exploration of the technical specifications, we pivot towards the future developments and innovations in material handling technologies. Join us in anticipating the advancements that may shape the landscape of steel production and crane design.

Operational Features

Control Mechanisms and Automation

The operational prowess of the 5 Ton Storage Bridge Crane is enhanced through sophisticated control mechanisms and automation, making it a versatile and efficient tool in steel production.

- Variable Frequency Drives (VFD): The incorporation of VFD in the crane's motors allows for precise control over the speed and acceleration of movements. This not only ensures smooth and controlled material handling but also contributes to energy efficiency by adjusting power consumption based on the load and operational requirements.

- Radio Remote Control: Many modern cranes are equipped with radio remote control systems. This technology enables operators to control the crane from a safe distance, providing a clear vantage point for maneuvering. The wireless remote control enhances operational flexibility and ensures that operators have a comprehensive view of the workspace.

- Automation Systems: Automation plays a pivotal role in the crane's operational efficiency. Automated functions, such as programmed lifting and transport sequences, contribute to the seamless execution of tasks. Automation not only reduces the dependency on manual operation but also enhances the precision and repeatability of movements.

Adaptability to Different Coil Sizes

The 5 Ton Storage Bridge Crane exhibits a remarkable level of adaptability to varying coil sizes, adding to its versatility in the ever-changing landscape of steel production.

- Adjustable Trolley Positioning: The trolley's lateral movement along the bridge girder is often adjustable, allowing for flexible positioning to accommodate different coil sizes. This adaptability ensures that the crane can efficiently handle various materials without the need for extensive adjustments.

- Variable Spreaders or Hooks: The crane's hoisting mechanism may feature variable spreaders or hooks that can be adjusted to securely grip different sizes of steel coils. This adaptability eliminates the need for frequent changes in equipment, streamlining the handling process for diverse materials.

- Load Sensing Technology: Some cranes are equipped with load sensing technology that automatically adjusts operational parameters based on the weight of the load. This ensures optimal performance and safety, regardless of the specific dimensions of the steel coils being handled.

As we conclude our exploration of the operational features, we transition to the final section of our journey—anticipating future developments and innovations in material handling technologies. Join us as we peer into the horizon of possibilities that may shape the next generation of industrial equipment, including the role of advanced technologies in enhancing efficiency and safety.

Conclusion

In the intricate choreography of steel production, the 5 Ton Storage Bridge Crane emerges as a linchpin, orchestrating the seamless handling and transportation of 5-ton steel coils within the confines of a production plant. Its importance reverberates through the corridors of efficiency, safety, and resource optimization, reshaping the landscape of industrial operations.

As we reflect on our journey through the realms of application, project s, benefits, and technical specifications, a comprehensive summary of the benefits and key features of the 5 Ton Storage Bridge Crane takes center stage:

- Efficiency: The crane streamlines material handling processes, minimizing downtime and ensuring a continuous flow in rolled steel production.

- Safety: Equipped with features ensuring safe coil handling, the crane reduces potential workplace accidents through precision controls and strategic design.

- Cost-Effectiveness: By optimizing resources in steel production, the crane contributes to labor efficiency, energy efficiency, and material utilization, offering long-term economic advantages.

- Technical Specifications: The crane's structural components, including the bridge girder, trolley, hoist, and end trucks, are meticulously crafted from high-strength steel alloys, ensuring durability. Operational features, such as VFD, radio remote control, and automation, enhance its adaptability and precision.

In the ever-evolving landscape of steel production, the 5 Ton Storage Bridge Crane stands as a beacon of innovation and efficiency. Its role in optimizing steel production extends beyond the lifting and transport of steel coils—it encapsulates a commitment to precision, safety, and sustainability.

As technology continues to advance, and the demands of the industry evolve, the crane remains a stalwart companion in the pursuit of excellence. Its adaptability to different coil sizes, automation capabilities, and long-term economic advantages position it as a vital asset in the arsenal of steel manufacturers.

In conclusion, the 5 Ton Storage Bridge Crane is not just a mechanical marvel; it is a catalyst for progress, propelling the steel production industry towards new heights of efficiency, safety, and economic sustainability. As we bid farewell to this exploration, we anticipate a future where innovation continues to redefine the boundaries of industrial achievement, and the crane continues to play a pivotal role in shaping the steel production landscape.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch