Your Trusted Overhead Crane Manufacturer & Supplier

30 Ton Overhead Crane for Sale

30 Ton Overhead Cranes Tailored for Your Industrial Needs

Cheaper Eot Crane Kits & Afforable Overhead Bridge Crane Turnkey Solutions

30 Ton Overhead Crane for Sale

30 ton overhead cranes are a practical solution for handling heavy materials in industrial settings. They are built to lift large loads safely, move them efficiently across workshops, and support daily operations where tons of steel, machinery, or molds need to be transported.

Choosing the right crane is not just about the weight it can lift. You also need to decide between a crane kit or a turnkey system. A kit gives flexibility for local fabrication and can reduce shipping costs, but it requires precise installation and some technical know-how. A turnkey solution, on the other hand, arrives fully assembled and tested, ready to operate immediately—simplifying installation but usually at a higher upfront cost.

Typical Applications

30 ton overhead cranes are widely used across industries that demand heavy lifting and precise handling:

- Steel mills: For moving slabs, billets, and coils. High temperatures and heavy loads make a robust crane essential.

- Metal fabrication: Handling large assemblies, machine parts, and structural components efficiently within a workshop or warehouse.

- Shipbuilding: Transporting hull sections, engines, and other bulky parts across long spans.

- Plastic injection and mold handling: Safely lifting large molds and presses, often with dual-hook setups for precision.

- Heavy machinery plants: Moving large engines, presses, or fabrication tools for assembly and maintenance.

Design Note

30 ton, 32 ton, and 35 ton overhead cranes often share similar structural designs. The main differences are usually in strengthened girders, upgraded hoists, or more powerful motors to safely handle heavier loads. This similarity makes planning, maintenance, and even operator training easier when working with cranes in this range.

30 Ton Overhead Cranes: Types and Typical Configurations

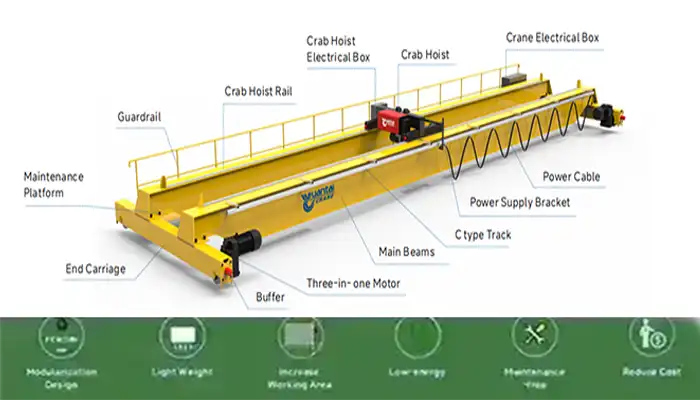

A. Structural Design

Heavy-duty 30 ton overhead cranes usually adopt a double girder configuration, with the double box girder design being the most common. This structure provides the strength and rigidity needed for lifting very heavy loads while minimizing deflection over long spans.

The lifting system can be configured in different ways depending on the specific needs of your facility:

- Hoist crab trolley: Compact, suitable for moderate lifting heights, and ideal for precise positioning.

- Open winch trolley: Designed for higher lifting heights and larger spans, offering more flexibility for heavy industrial applications.

Choosing the right trolley depends on the weight of the load, the travel distance, and the operational frequency

Hoist Trolley Options

Selecting the correct hoist trolley is crucial for both efficiency and safety. Here's a comparison:

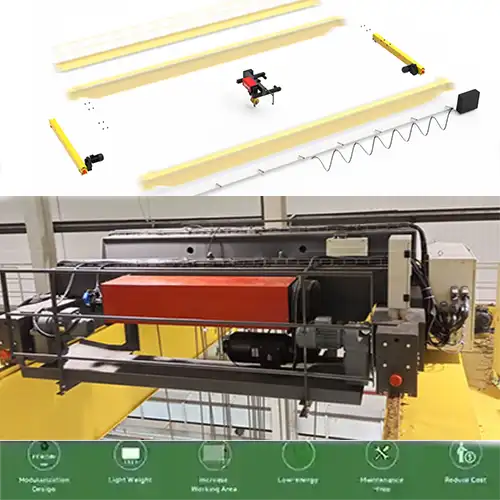

Hoist crab trolley, the one in the picture is the European style low headroom hoist trolley for your reference

- Pros: Precise load positioning, easier maintenance, compact design.

- Cons: Limited lifting height, may require additional structural reinforcement for very heavy loads.

- Pros: Capable of very high lifting heights, suitable for long spans, handles heavier loads.

- Cons: Larger footprint, more complex maintenance, and higher initial cost.

Specialized Designs

Some applications require cranes that go beyond standard configurations. Specialized 30 t overhead cranes include:

- Explosion-proof cranes for hazardous environments such as chemical plants or areas with flammable materials.

- Outdoor cranes with protective coatings and weatherproof components for long-term durability.

- Cranes equipped with grab buckets or magnetic spreaders, which are often used in steel mills, scrap handling, or material sorting operations.

explosion proof open winch trolley for explosion proof cranes

Overhead Crane Kits vs Overhead Bridge Crane Turnkey Solutions

When purchasing a 30 t overhead crane, buyers generally have two options:

Crane Kit

- Supplied components: hoist, trolley, end carriages, control system.

- Buyer provides: steel girders, runway beams, and installation.

- Benefits: Lower shipping cost, flexibility for local fabrication, easier long-term maintenance.

- Considerations: Requires technical expertise for installation, precise alignment, and quality control.

Turnkey Overhead Crane System and Projects for Yours

- Supplied as a complete system including girders, installation, testing, and commissioning.

- Benefits: Ready to operate immediately, reduced installation complexity, supplier guarantees performance.

- Considerations: Higher upfront cost, more complex shipping logistics.

Comparison Summary:

- Cost: Kits generally lower upfront cost, turnkey higher.

- Lead time: Turnkey may take longer to deliver but saves time during installation.

- Customization: Kits allow local adjustments; turnkey is mostly fixed.

- Local fabrication: Kit requires fabrication capability; turnkey does not.

Selecting the right option depends on your facility's capabilities, budget, and operational priorities.

Key Specifications and Buyer Considerations

When evaluating a 30 ton overhead crane, understanding the key specifications is essential. Each factor affects not only the crane's lifting performance but also its safety, longevity, and suitability for your facility. Buyers often focus on load capacity, operational height, environmental conditions, and compliance with industry standards. Taking the time to assess these elements before purchase can prevent costly mistakes and downtime later.

Here are the main specifications and considerations for a 30 t overhead crane:

- Lifting capacity: Main hook rated at 30 t. For facilities that handle varying load sizes, an auxiliary hook or dual-hook configuration may be required for lighter, repetitive lifts.

- Span & height: The crane's span and lifting height affect both the structural design of the girders and the overall stability of the system. Longer spans may require stronger girders and reinforced runway beams.

- Duty class: Typically A5 or A6, depending on the frequency of lifts and operational intensity. Heavier, repeated lifts demand a higher duty class to ensure safe operation over time.

- Power supply & control: Voltage, phases, and control options must match your facility's infrastructure. Pendant, wireless remote, or cabin controls are all possible depending on operational preference and safety requirements.

- Environmental factors: Cranes may be installed indoors or outdoors, and conditions such as temperature extremes, dust, or corrosive atmospheres must be considered when selecting materials, coatings, and protective features.

- Hoist and trolley selection: Choose between single or double trolley setups, and select motors and gearboxes that provide smooth operation under full load. Matching hoist speed and trolley travel to your workflow improves efficiency.

- Safety and compliance: Ensure mechanical, electrical, and structural certifications meet industry standards. Compliance guarantees safe operation and often affects insurance coverage and regulatory approval.

30 Ton Overhead Crane Kit for Sale and Buyer Considerations

A 30 ton overhead crane kit is an attractive option for industrial buyers who have local fabrication capabilities. It allows facilities to take advantage of lower shipping costs and to customize the steel structure to fit their specific workshop or plant layout. However, purchasing a crane kit also requires careful planning to ensure safe installation, proper alignment, and long-term operational reliability.

Suitability

Crane kits are best suited for buyers who can fabricate girders and prepare the runway locally. If your facility has welding expertise, structural fabrication capacity, and skilled technicians, a crane kit offers flexibility and cost savings.

Advantages

Purchasing a crane kit offers several practical benefits:

- Lower freight cost: Transporting components rather than a fully assembled crane reduces shipping expenses significantly.

- Local customization of steel structure: Buyers can adapt the crane's dimensions or design to fit unique plant layouts or workflow requirements.

- Easier maintenance and component replacement: With locally fabricated girders, components can be accessed, serviced, or replaced without depending on long-distance supplier support.

Challenges

While crane kits provide flexibility, there are some challenges buyers should anticipate:

- Precise installation required: Proper alignment and assembly are critical to ensure safe and smooth crane operation.

- Quality control for locally fabricated girders: Ensuring welding and structural standards meet design specifications is essential.

- Coordination with supplied components: Hoist, trolley, and control systems must integrate perfectly with the fabricated girders and runway.

Checklist for Kit Buyers

Before committing to a crane kit, buyers should verify the following:

- Confirm fabrication capability and welding standards at the local facility.

- Ensure runway beams are prepared accurately and aligned properly.

- Verify that installation and commissioning support from the supplier is available if needed.

Turnkey Solution Considerations

A turnkey 30 ton overhead crane is designed for buyers who want a fully installed, ready-to-use system with minimal onsite assembly. This solution is ideal for facilities that may not have local fabrication capability or prefer to rely on the supplier for complete installation and testing. Turnkey cranes are particularly attractive for projects where time, reliability, and guaranteed performance are top priorities.

Suitability

Turnkey cranes are best suited for buyers who want a hassle-free installation process and a fully operational crane without the need for local fabrication. Facilities with tight deadlines, limited technical staff, or complex operational requirements often find turnkey solutions more practical.

Advantages

Purchasing a turnkey crane offers several clear benefits:

- Quick deployment: The crane arrives largely pre-assembled, reducing the time needed for onsite installation.

- Supplier guarantees for installation and performance: Buyers can rely on the supplier for correct assembly, calibration, and initial testing.

- Integrated testing and commissioning: The crane is tested under real load conditions before being handed over, ensuring it meets safety and performance standards.

Considerations

Despite the advantages, turnkey solutions also have factors buyers should consider:

- Higher upfront cost: Complete installation and testing are included in the price, which can be higher than a kit-based approach.

- Limited local customization: The crane design is mostly fixed, which may limit adjustments for specific plant layouts.

- Shipping and logistics: Moving fully assembled components may require careful planning, particularly for large spans or remote locations.

Choosing between a crane kit and a turnkey solution ultimately depends on your facility's technical capabilities, budget, and project timeline. Turnkey cranes provide convenience and reliability, while kits offer flexibility and cost savings when local fabrication is feasible.

Your Trusted 30 Ton Overhead Crane Manufacturer & Supplier